Marco den Engelsman

Blooming Bryony Designs printed onto cotton bags and cushion covers.Direct-to-garment printing, or DtG, is one of the buzzwords we are starting to hear more and more often in wide format circles. It basically means using a digital printer to print directly onto clothes and accessories, and the process is turning a lot of heads.

For entrepreneurial designers and printers looking to provide new services, DtG is a no brainer because it is ideal for short runs. DtG makes garment design and printing simple, accessible and cheap, especially compared to traditional screen printing. Put a DtG printing system at the back of a web to print platform, supporting online customisation and order processing, and you have all the ingredients for an exciting new business model.

DtG print using inkjet technology is attractive because the process of creating a printed garment from scratch using traditional technologies can be long and complicated. The printers are easy to use, affordable and print great quality images directly onto a variety of small to medium format shirts and accessories quickly.

Killer apps

Different fabrics will have different characteristics making them suitable for different types of design and the printed result must also be able to withstand washing. The inks must stick to the fibres and not lose their colour too readily despite the weather or how often they are washed. And, of course, the fabric must look and feel natural and not irritate its wearer.

Inkjet printing technologies are available in many flavours and can be configured to print on natural fibres, polyesters and blends, without compromising the feel of the end result. The reduction in production steps, compared to traditional processes, and the technology options also means that the cost of production can come down. This makes it possible for anyone to print their own garments – with relatively little expertise – and supports business models that offer a high profit per garment.

Along with reliability and productivity, cost is one of the main drivers when it comes to choosing the right production technology for your wide format project. But cost can be subjective and is always relative. For instance, if you are printing more than a couple of hundred T-shirts, all of which are the same, you are probably better off with conventional screen printing. If you want each T-shirts to be different and you want them printed in a four-colour photographic process, digital printing using a compact, DtG desktop printer is really your only cost effective option. This is especially true if you have a multilayered halftoned design and you are not using specialty inks such as metallics. The high worth nature of bespoke garments is also something to consider in your DtG project planning. This is one of the reasons why DtG digital printing is rapidly taking off.

Cushions pinted live at Heimtextil 2015 using the Epson SureColor SC-F2000 direct to fabric printer wrapped in personalised ribbons printed on the Epson LabelWorks LW-400 QZ.

Suits you sir!

Compared to conventional garment printing DtG has a much shorter supply chain and has a much quicker production turnaround. Unlike screen printing, which requires the preparation of a screen per colour, digital inkjet printing enables you to print a multicoloured image direct to the garment in just a few minutes. Plus, with a DtG production line, digital colour management ensures that the colours a designer intends are the colours the printing system delivers.

DtG printing systems can exploit the sophisticated and widespread modern prepress workflow technologies used in commercial print and publishing. These workflows can handle a wide range of output options, and although the workflow management technologies are relatively new to DtG production, the basic principles of production and colour management can still be applied.

Digital DtG printing systems are available that handle all pre- and post-treatment to produce T-shirts, sportswear and other items of clothing and accessories – such as baby grows, hats, bags, napkins and T Towels – on demand. Manufacturers large and small, are getting into the DtG act, but the biggest is Epson which has been involved in this field for several years and is fast becoming the best known name in the DtG field. The SureColor SC-F2000 for instance is a DtG digital printer that Epson has specifically designed to print direct to garments. Other devices available include the Anajet which is distributed by Ricoh. This printer requires pre and post treatments, using heat to cure the water based pigment inks. Kornit is another option, with platforms designed for on-demand DtG as well as mass production.

Planning your move

Workflow is what makes or breaks pretty much any project, so make sure you think things through beforehand. When you create your design, consider the application you will use to do it. Ideally you want something that supports different output formats, so that you can optimise your files for different printing systems. At the very least you need to be able to create raster files as JPEGs and TIFFs. Consider the output size of your garment and make sure that the printing system can support it. Look for a system that provides a choice of platen sizes and that the system’s layout software can position your file as you want it. Your design may need to scaled or otherwise adjusted to fit the platen.

Also ensure that the layout tool can adjust colours as needed and control the amount of ink that is laid down. Apart from concerns about quality, such as infilling in your design, using more ink than you need means you may be spending more than you should. The materials you are printing onto should also be rated for stain and rub resistance, ideally with a rating from the AATCC which has a international standard method for testing fibers and fabrics. These tests measure a range of performance criteria such as visual appearance, colour fastness, water resistance and dimensional change. ISO 105-E01 is another standard test for colour fastness in water.

DtG shops are starting to popup on high streets and on line. Mad-in-Berlin for example has two locations in the city digitally printing souvenirs and T-shirts on demand, and has a healthy online business too. Basic products such as a Yoko backpack can be customised with your name and images, or you can create your own products from blank generics either at the website or in one of the Mad-in-Berlin shops. Perhaps you want high visibility jackets with your logo and web address? Or rain ponchos with the map of where you want to go hiking? Maybe you even want to sell ponchos printed with local maps from a village shop out in the countryside? Creating such high value items is what DtG is all about and it’s a perfect way to come up with ideas that capitalise on bespoke, customised and localised production.

In much the same way as digital printing technologies are upending conventional print, so the same thing is starting to happen with garment printing. It’s too early to say when DtG printing will become a totally digital industry. But if you are interested in short runs, prototyping and customised garments the possibilities available to you are about to get very interesting.

Sophie Matthews-Paul

The Wild Format guides are intended to expand awareness and understanding of the craziness that can be created on wide format digital printing devices, from floors to lampshades and everything in between.

These guides are made possible by a group of manufacturers working together with Digital Dots.

This article is supported by Mimaki (www.mimakieurope.com) and Digital Dots (www.digitaldots.org).

Together we hope you enjoy the articles and that you put into practise what you learn. If you want to talk about it, go to our LinkedIn group via this link.

Enjoy and Go Wild!

Lees verder.... Verpakkingsdrukkerij Acket in Oss investeert in een grote nieuwe hal en een splinternieuwe drukpers, zo meldt de Brabantse nieuwssite BD.

Verpakkingsdrukkerij Acket in Oss investeert in een grote nieuwe hal en een splinternieuwe drukpers, zo meldt de Brabantse nieuwssite BD.

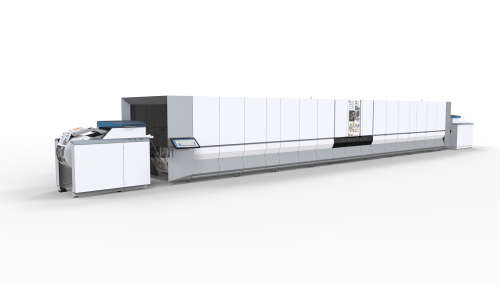

De buitenkant is zo goed als af, de vloer ligt er in en ook het fundament voor de drukpers is al gestort. In een nieuwe hal van zo’n duizend vierkante meter kan Acket aan de Gasstraat-Oost straks sneller drukken dan ooit tevoren. Vanaf komende zomer rollen er verpakkingen voor onder meer koffie, hagelslag en rijst van de band.

Tel er de nieuwe vouwplakmachine en het nieuwe recyclingsysteem van het bedrijf bij op en je spreekt van een miljoeneninvestering. Een stap die Acket kan zetten dankzij een gestage groei in de laatste jaren. Het exacte bedrag dat besteedt wordt aan hal en machines houdt het bedrijf geheim.

Acket werkt onder meer voor Lidl, Plus, De Ruyter en Lassie. Jaarlijks rollen er zo’n 600 miljoen verpakkingen van de band. Via de klanten van Acket belanden die in keukenkastjes over de hele wereld. Bij het bedrijf werken ongeveer 135 mensen. Dat aantal blijft na de uitbreiding gelijk.

Blooming Bryony Designs printed onto cotton bags and cushion covers. Direct-to-garment printing, or DtG, is one of the buzzwords we are starting to hear more and more often in wide format circles. It basically means using a digital printer to print directly onto clothes and accessories, and the process is turning a lot of heads.

For entrepreneurial designers and printers looking to provide new services, DtG is a no brainer because it is ideal for short runs. DtG makes garment design and printing simple, accessible and cheap, especially compared to traditional screen printing. Put a DtG printing system at the back of a web to print platform, supporting online customisation and order processing, and you have all the ingredients for an exciting new business model.

DtG print using inkjet technology is attractive because the process of creating a printed garment from scratch using traditional technologies can be long and complicated. The printers are easy to use, affordable and print great quality images directly onto a variety of small to medium format shirts and accessories quickly.

Killer apps

Different fabrics will have different characteristics making them suitable for different types of design and the printed result must also be able to withstand washing. The inks must stick to the fibres and not lose their colour too readily despite the weather or how often they are washed. And, of course, the fabric must look and feel natural and not irritate its wearer.

Inkjet printing technologies are available in many flavours and can be configured to print on natural fibres, polyesters and blends, without compromising the feel of the end result. The reduction in production steps, compared to traditional processes, and the technology options also means that the cost of production can come down. This makes it possible for anyone to print their own garments – with relatively little expertise – and supports business models that offer a high profit per garment.

Along with reliability and productivity, cost is one of the main drivers when it comes to choosing the right production technology for your wide format project. But cost can be subjective and is always relative. For instance, if you are printing more than a couple of hundred T-shirts, all of which are the same, you are probably better off with conventional screen printing. If you want each T-shirts to be different and you want them printed in a four-colour photographic process, digital printing using a compact, DtG desktop printer is really your only cost effective option. This is especially true if you have a multilayered halftoned design and you are not using specialty inks such as metallics. The high worth nature of bespoke garments is also something to consider in your DtG project planning. This is one of the reasons why DtG digital printing is rapidly taking off.

Cushions pinted live at Heimtextil 2015 using the Epson SureColor SC-F2000 direct to fabric printer wrapped in personalised ribbons printed on the Epson LabelWorks LW-400 QZ.

Suits you sir!

Compared to conventional garment printing DtG has a much shorter supply chain and has a much quicker production turnaround. Unlike screen printing, which requires the preparation of a screen per colour, digital inkjet printing enables you to print a multicoloured image direct to the garment in just a few minutes. Plus, with a DtG production line, digital colour management ensures that the colours a designer intends are the colours the printing system delivers.

DtG printing systems can exploit the sophisticated and widespread modern prepress workflow technologies used in commercial print and publishing. These workflows can handle a wide range of output options, and although the workflow management technologies are relatively new to DtG production, the basic principles of production and colour management can still be applied.

Digital DtG printing systems are available that handle all pre- and post-treatment to produce T-shirts, sportswear and other items of clothing and accessories – such as baby grows, hats, bags, napkins and Tea Towels – on-demand. Manufacturers large and small, are getting into the DtG act, but the biggest is Epson which has been involved in this field for several years and is fast becoming the best known name in the DtG field. The SureColor SC-F2000 for instance is a DtG digital printer that Epson has specifically designed to print direct to garments. Other devices available include the Anajet which is distributed by Ricoh. This printer requires pre and post treatments, using heat to cure the water-based pigment inks. Kornit is another option, with platforms designed for on-demand DtG as well as mass production.

Planning your move

Workflow is what makes or breaks pretty much any project, so make sure you think things through beforehand. When you create your design, consider the application you will use to do it. Ideally you want something that supports different output formats, so that you can optimise your files for different printing systems. At the very least you need to be able to create raster files as JPEGs and TIFFs. Consider the output size of your garment and make sure that the printing system can support it. Look for a system that provides a choice of platen sizes and that the system’s layout software can position your file as you want it. Your design may need to scaled or otherwise adjusted to fit the platen.

Also ensure that the layout tool can adjust colours as needed and control the amount of ink that is laid down. Apart from concerns about quality, such as infilling in your design, using more ink than you need means you may be spending more than you should. The materials you are printing onto should also be rated for stain and rub resistance, ideally with a rating from the AATCC which has a international standard method for testing fibers and fabrics. These tests measure a range of performance criteria such as visual appearance, colour fastness, water resistance and dimensional change. ISO 105-E01 is another standard test for colour fastness in water.

DtG shops are starting to popup on high streets and on line. Mad-in-Berlin for example has two locations in the city digitally printing souvenirs and T-shirts on demand, and has a healthy online business too. Basic products such as a Yoko backpack can be customised with your name and images, or you can create your own products from blank generics either at the website or in one of the Mad-in-Berlin shops. Perhaps you want high visibility jackets with your logo and web address? Or rain ponchos with the map of where you want to go hiking? Maybe you even want to sell ponchos printed with local maps from a village shop out in the countryside? Creating such high value items is what DtG is all about and it’s a perfect way to come up with ideas that capitalise on bespoke, customised and localised production.

In much the same way as digital printing technologies are upending conventional print, so the same thing is starting to happen with garment printing. It’s too early to say when DtG printing will become a totally digital industry. But if you are interested in short runs, prototyping and customised garments the possibilities available to you are about to get very interesting.

Sophie Matthews-Paul

The Wild Format guides are intended to expand awareness and understanding of the craziness that can be created on wide format digital printing devices, from floors to lampshades and everything in between.

These guides are made possible by a group of manufacturers working together with Digital Dots.

This article is supported by Mimaki (www.mimakieurope.com) and Digital Dots (www.digitaldots.org).

Together we hope you enjoy the articles and that you put into practise what you learn. If you want to talk about it, go to our LinkedIn group via this link.

Enjoy and Go Wild!

Lees verder....

De Persgroep heeft 2016 afgesloten met een recordomzet en een winststijging.

De Persgroep heeft 2016 afgesloten met een recordomzet en een winststijging.

De groei is voornamelijk te danken aan overnames die in de loop van 2015 werden gedaan en die voor een volledig jaar meetelden in 2016, zoals die van Wegener in Nederland, Berlingske Media in Denemarken en onder meer Humo en Story in België (die van Sanoma werden overgenomen).

De omzet was ruim 1,4 miljard euro.

De netto courante winst steeg tot 117 miljoen euro (+7%). De ‘netto financiële schuld’ van de groep bedroeg 22 miljoen euro.

De kranten van de groep wisten hun lezersomzet stabiel te houden. De inkomsten uit printabonnementen vielen licht terug, maar dat werd gecompenseerd door een groei uit digitale en hybride (digitaal plus zaterdagkrant) abonnementen.

(bron: Adformatie)

Voor de tweede keer in vier jaar organiseert de internationale Ghent Workgroup (GWG) de PDF Survey, een grote enquête naar de toepassing van PDF workflows onder zoveel mogelijk gebruikers.

Voor de tweede keer in vier jaar organiseert de internationale Ghent Workgroup (GWG) de PDF Survey, een grote enquête naar de toepassing van PDF workflows onder zoveel mogelijk gebruikers.

Door middel van dit onderzoek wil de GWG zicht krijgen op de manier waarop die workflows in de afgelopen jaren zijn veranderd, welke specificaties er worden toegepast en hoe de processen onderling verschillen. De uitkomsten worden gebruikt om de PDF-specificaties en de overige tools en aanbevelingen van de GWG te optimaliseren. In deze video legt David Zwang van de GWG nog een keer uit waarom deelname aan de survey van belang is. Als dank voor je tijd maak je kans op een aantal mooie prijzen, die onder de deelnemers worden verloot. Doe dus mee en klik hier om de survey te starten.

In Eindhovens Dagblad staat een artikel over de specialist in Super grootformaat printen Big Impact in Eindhoven.

In Eindhovens Dagblad staat een artikel over de specialist in Super grootformaat printen Big Impact in Eindhoven.

Samen met fabrikant Durst ontwikkelde het bedrijf een UV printtechniek die reliefprinten op grote formaten mogelijk maakt

Pionier Marc Schoenmakers is met zijn bedrijf Big Impact in Eindhoven weer een nieuw avontuur begonnen.

Schoenmakers heeft een nieuwe markt voor ogen voor wat hij printen in 2,5 D noemt. Printen in braille. Een plattegrond voelbaar maken. Een kunstreproductie met reliëf. Tastbare objecten in musea voor kinderen. ,,Dat moet nieuwe kansen geven”, is zijn overtuiging.

Big Impact ontwikkelde de machine samen met zijn leverancier, Durst De machine voor zogenoemde haptic (voelbaar) printing van Durst wordt bij Big Impact verder uitontwikkeld. Eind dit jaar zou het ontwikkeltraject van alles bij elkaar twee jaar moeten zijn afgerond. De inkt die uithardt onder invloed van UV-licht kan nu laagje voor laagje worden gestapeld tot een hoogte van 0,6 millimeter. De machine kan nu met een snelheid van 6 vierkante meter per uur in reliëf drukken. Daar moeten nog stappen in worden gezet.

Uit de machine die een investering van 500.000 euro vergt, komen nu testproducten. ,,We zijn ons aan het bekwamen in het maken van ontwerpen waarbij de techniek tot zijn recht komt.”

De nieuwe boekenbarometer en e-bookbarometer van CB laten zien dat de groei in e-bookverkoop geleidelijk aan minder hard stijgt en dat het aandeel fysieke boeken dat via internet is verkocht gegroeid is met 3,4%.

De nieuwe boekenbarometer en e-bookbarometer van CB laten zien dat de groei in e-bookverkoop geleidelijk aan minder hard stijgt en dat het aandeel fysieke boeken dat via internet is verkocht gegroeid is met 3,4%.

Het genre romantiek is naar verhouding beter vertegenwoordigd in de e-bookafzet dan in de afzet van fysieke boeken. Voor het fysieke boek geldt dat fictie, kinderen en Young Adult het sterkst vertegenwoordigd zijn. De afzet van het fysieke boek laat in genres een bredere spreiding zien, dan de afzet van e-books.

Het aantal beschikbare e-booktitels stijgt flink voor uitleen (bibliotheken): een plus van 6.180 ofwel 68% ten opzichte van het vorige kwartaal. Ondanks dat er nog te weinig omzetcijfers beschikbaar zijn rondom e-bookabonnementen, zien we ook daar het aantal beschikbare titels stijgen: met 5.769 ofwel 67%.

Nieuw is de grafiek waarin zichtbaar wordt in welk prijssegment de meeste e-books en boeken verkocht zijn. Voor e-books geldt dat in het prijssegment €8,00 – €9,99 het grootste aantal is verkocht. Voor fysieke boeken zijn het prijssegment €12,50 – 14,99 en €17,50 – 19,99 het meest omvangrijk. De gemiddelde prijs van een e-book daalt bovendien nog steeds (is nu 50,3% van de gemiddelde fysieke prijs).

Andere opvallende zaken zijn de afwisseling tussen koop en huur in de e-bookbarometer en de daling van de afzet van het fysieke met boek met -3,6% ten opzichte van hetzelfde kwartaal in 2016.

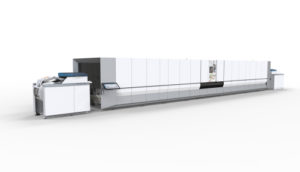

Ipskamp Printing breidt haar printerpark uit met de Océ ProStream 1000: de ‘next generation’ rotatieve kleuren inkjet-productieprinter van Canon. De ProStream combineert de beste eigenschappen van bestaande high performance inkjettechnologieën met Canon-innovaties, om de kleurkwaliteit en flexibele inzetbaarheid van snelle, rotatieve inkjet-productieprinters naar een nog hoger niveau te tillen. Voor Ipskamp Printing biedt dit mogelijkheden om klanten hoogwaardige producten met variabele content aan te bieden. Ipskamp Printing is het eerste bedrijf in Nederland dat investeert in de nieuwe ProStream.

Ipskamp Printing breidt haar printerpark uit met de Océ ProStream 1000: de ‘next generation’ rotatieve kleuren inkjet-productieprinter van Canon. De ProStream combineert de beste eigenschappen van bestaande high performance inkjettechnologieën met Canon-innovaties, om de kleurkwaliteit en flexibele inzetbaarheid van snelle, rotatieve inkjet-productieprinters naar een nog hoger niveau te tillen. Voor Ipskamp Printing biedt dit mogelijkheden om klanten hoogwaardige producten met variabele content aan te bieden. Ipskamp Printing is het eerste bedrijf in Nederland dat investeert in de nieuwe ProStream.

De Ghent Workgroup vindt dat het tijd is voor een update rond het gebruik van de nieuwe PDF-standaarden in de grafische industrie.

De Ghent Workgroup vindt dat het tijd is voor een update rond het gebruik van de nieuwe PDF-standaarden in de grafische industrie.

Klanten of ontwerpers zijn (soms) moeilijk te overtuigen om opmaakfiles op een goede manier te controleren. De foutmeldingen of omschrijvingen zijn soms te technisch voor een leek om te begrijpen wat er juist mis is met een file.

Toch zijn de PDF-standaarden belangrijk. Ze voorkomen dat er een aantal veel voorkomende problemen in files zitten, dat er misinterpretaties zijn omtrent de visualisatie of verwerking van een PDF.

Zijn PDF workflows of tools geëvolueerd? Gebruiken designers of drukkers de nieuwe op PDF/X-4 gebaseerde preflight-profielen, of werkt iedereen nog altijd met PDF/X-1a?

Graag willen we u vragen om de nieuwe GWG-enquête rond het gebruik van PDF-standaarden in te vullen via deze link. Deelname duurt niet lang! Daarnaast maakt u kans om één van de interessante prijzen te winnen, aangeboden door de Ghent Workgroup-leden.

Bedankt alvast voor uw deelname! De resultaten delen we graag in één van de volgende edities van onze nieuwsbrief Eye-Opener met u mee.

Lees verder.... Californian student Aaron Levie started his cloud services business Box 12 years ago. Box now has more than 70,000 customers of which 64% are the 500 biggest companies on the planet.

Californian student Aaron Levie started his cloud services business Box 12 years ago. Box now has more than 70,000 customers of which 64% are the 500 biggest companies on the planet.

During the Box World Tour Levie talks, together with visionaries from Google and IBM, about the future of digitalisation. Visions that are interesting for any company.

Mobility

“Mobility is the greatest change of the past 10 years. It is a reality that everyone can work from any location and that every person can use on demand services at any moment suitable to them. That is no longer science fiction, it is now.” according to Aaron Levie. “It is a trend that has completely changed doing business. It is available for any company. Apart from that the cost of storage is so low that everyone can use the cloud for storage. More and more people work via a global company network.”

Digital thinking

“Every company will have to become digital. And companies that are already digital will have to become even more digital” says Levie. “But it´s not that simple. We see many companies that think that digital business is just a layer of software. They think that if you have good internet access and clients can order online they have made the step to digital. What we see is that these companies have not changed. Everything remains the same.”

“Clients, however, are dealing with this new freedom in a completely different way. Netflix is a good example. The success of this company is not because of their cool app. Netflix was born from the idea of offering content to people when they want it in an affordable way. On top of that they have cool unique content which makes it a new personalised business model. All others who have only made the change from lending DVDs to an online model have missed the boat. They continued with their current business model and made it digital.”

New capabilities

“The capabilities we developed during the industrialisation are now under pressure. The time that we produced first and then sold is completely over. But models such as optimisation and work flow control are based on that. If you want to go digital you will have to do this together with your partners because you are as fast as your slowest partner. Every branche will be affected by these new digital companies and platforms which disrupt current industries. Examples such as Netflix, AirBnB and Uber can be found in any industry. It is because these sort of platforms that give clients a new experience which they then expect elsewhere.”

On demand

“The digital business model consists of services on demand. Paying only when using. Everything is for rent and nothing has to be bought. Everything can be used only when we need it. IT used to be a part of the balance sheet with software according to tradition. Other parts such as sales, production and management have their own software solutions geared towards process control.

Now the world is flat. IT will be the thing that makes the organisation grow.

In the near future the organisation will become flat and intelligent software will make the choices before you can make them. In the future technology such as is being used within Google will become available for everyone. Software such as artificial intelligence will find what is relevant for the user.

Cognitive

IBM have been working on this for a long time in project Watson. “Cognitive computing has changed the way employees work, in big and in small companies. One of the reasons is the possibility of direct access to knowledge which is buried deep within the company.” says Christopher C Crummey, global Executive Director of Evangelism and Customer Experience at IBM´s Watson Work Collaboration Services. “Using Cognitive Bots can help new employees during their first days at a company. New employees can use Cognitive Bots to get answers about subjects such as HR processes, IT tools, policies, procedures and get immediate answers.

Artificial intelligence

“We are facing a new computer era. The convergence of working in the cloud, more powerful mobile devices, bots and artificial intelligence can change productivity step by step” says Johann Butting, Head of Sales, EMEA, Slack. “By embracing this technology and use it for simple, daily tasks we can use our brains and creativity to solve difficult problems. The future of work is a universe in which technology offers discrete and personalised support for everyone. We are looking forward to being part of this journey.”

De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK