Rob van den Braak

Volgens KBA heeft zijn klant Winston Packaging het wereldrecord karton bedrukken. Op een zes kleuren Rapida106 bereikte de Amerikaanse drukker een gemiddelde snelheid van 18.964 druk per uur. De pers, geïnstalleerd in 2012, haalt normaal een gemiddelde snelheid van 17.000 druks. Het record was mogelijk door een perfecte partij 8pt C1S board en een op elkaar ingespeeld team van dit 103 jaar oude familie bedrijf in Salem, NC. Winston Packaging heeft nog een record wat zeker zo belangrijk is, het bedrijf heeft tot op heden 500.000 uren gewerkt zonder ongelukken en kreeg daarvoor een prijs van de Paperboard Packaging Council.

Volgens KBA heeft zijn klant Winston Packaging het wereldrecord karton bedrukken. Op een zes kleuren Rapida106 bereikte de Amerikaanse drukker een gemiddelde snelheid van 18.964 druk per uur. De pers, geïnstalleerd in 2012, haalt normaal een gemiddelde snelheid van 17.000 druks. Het record was mogelijk door een perfecte partij 8pt C1S board en een op elkaar ingespeeld team van dit 103 jaar oude familie bedrijf in Salem, NC. Winston Packaging heeft nog een record wat zeker zo belangrijk is, het bedrijf heeft tot op heden 500.000 uren gewerkt zonder ongelukken en kreeg daarvoor een prijs van de Paperboard Packaging Council. In haar Verdigris blog geeft Laurel Brunner een voorbeeld van hoe snel milieuregels kunnen veranderen. Het Ecoedicion Office, een Spaanse overheidsorganisatie, heeft Product Category Rules voor drukwerk bedacht. In deze regels staat hoe drukwerkmakers moeten omgaan met zaken als Life Cycle Management en milieuzorg als ze overheidsopdrachten willen vergaren. Lees hier hoe je het document kunt downloaden en waarom deze regelveranderingen die net zo snel en overwacht komen als variaties op rockmuziek belangrijk zijn voor de samenleving en de grafische industrie.

In haar Verdigris blog geeft Laurel Brunner een voorbeeld van hoe snel milieuregels kunnen veranderen. Het Ecoedicion Office, een Spaanse overheidsorganisatie, heeft Product Category Rules voor drukwerk bedacht. In deze regels staat hoe drukwerkmakers moeten omgaan met zaken als Life Cycle Management en milieuzorg als ze overheidsopdrachten willen vergaren. Lees hier hoe je het document kunt downloaden en waarom deze regelveranderingen die net zo snel en overwacht komen als variaties op rockmuziek belangrijk zijn voor de samenleving en de grafische industrie.

Lees verder....

In most progressive rock music, movement through its sound doesn’t necessarily happen smoothly or obviously. Often it is made in unexpected and unanticipated ways, which is the way of progress in most situations. Progress happens with little steps. We recently came across a lovely example of how it works in the real world of printing and publishing, in the Life and Ecoedicion office of the regional Ministry of the Environment for Andalucia in Spain. This is a local government office that wants to provide an example of green procurement and services. The office has set up a project to improve publishing and production processes and goods procurement, so that they are more environmentally friendly.

The idea is to produce a reference brand that printers and publishers recognise and support. The administration in Andalucia wants to promote sustainable publications and to provide consumers with complete and consistent environmental impact data. They expect this information to be a factor in purchasing decisions. The Ecoedicion Manual is a guidance document the adminstration has produced for its own publishing and distribution activities, however it is hoped that other publishers and municipalities will also use the manual. A campaign is underway to encourage other companies to join the network and nearly 80 Spanish printers and publishers from all over Spain have signed up so far. A pilot project is underway that includes various regional ministeries who have committed to publishing and printing green publications that will bear the Ecoedition ecolabel.

As part of this project the Life and Ecoedicion Office is developing Product Category Rules (PCR) for printed books. This is ambitious because Product Category Rules are difficult to develop for print media products. As far as we are aware only the Japanese Printers Federation is making a stab at it for the graphic arts. PCRs are important because they provide the basis for determining what should be covered in an environmental impact calculation. The work in Spain is intended to provide the partners in Ecoedicion with a common framework on which to base their calculations.

Having a PCR for printed books makes it possible for publishers to produce consistent Life Cyce Assessments for their products. The Ecoedicion Office’s PCR covers printed books of various types and provides the information to be addressed in an environmental impact calculation. If this work is of interest to you, you can find out more about it at http://www.environdec.com/en/PCR/Detail/?Pcr=7927#.VDJsBudYU7E, where the PCR is available for public comment. We are taking tiny steps but we can be confident that, like progressive rock, they will eventually make sense. Such is the way of progress.

Laurel Brunner

Dit blog wordt mogelijk gemaakt dankzij de bijdrage van: Agfa Graphics (www.agfa.com), Digital Dots (http://digitaldots.org), drupa (www.drupa.com), EFI (www.efi.com), Fespa (www.fespa.com), Heidelberg (www.uk.heidelberg.com), Kodak (www.kodak.com/go/sustainability), Mondi (www.mondigroup.com/products), Pragati Offset (www.pragati.com), Ricoh (www.ricoh.com), Shimizu Printing (www.shzpp.co.jp), Splash PR (www.splashpr.co.uk), Unity Publishing (http://unity-publishing.co.uk) and Xeikon (www.xeikon.com).

BlokBoek.com is de Nederlandse media-partner van Verdigris, een non-profit initiatief dat de werkelijke voetprint van druk- en printwerk die drukwerk achterlaat eerlijk in kaart wil brengen en dat bedrijven en organisatie steunt om die voetprint te verlagen.

Meer informatie over Verdigris vindt je via deze link.

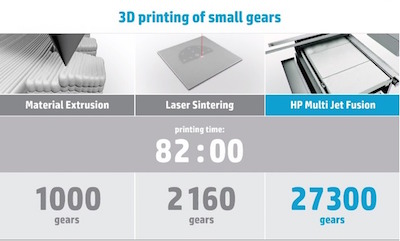

Met de vooraankondiging van zijn zelf ontwikkelde 3D printtechniek, beschikbaar 2e helft van 2016, neemt HP eindelijk zijn eerste stapje in de groeiende 3D markt. Met vijf klanten test HP zijn thermal inkjet 3D printtechniek die met multi jet fusion volgens vice president en general manager Ramon Pastor moet kunnen concurreren met marktleiders zoals Stratasys en 3D Systems. HP Multi Jet Fusion moet productieve en kwalitatief hoogwaardige 3D printsystemen opleveren die rond de 1 miljoen dollar gaan kosten. Of HP ook aan betaalbare ‘tafelmodellen’ werkt is niet bekend, maar dat zou niemand verbazen als je kijkt naar hoe de HP Deskjet printers de markt voor grotere systemen opengebroken heeft.

Met de vooraankondiging van zijn zelf ontwikkelde 3D printtechniek, beschikbaar 2e helft van 2016, neemt HP eindelijk zijn eerste stapje in de groeiende 3D markt. Met vijf klanten test HP zijn thermal inkjet 3D printtechniek die met multi jet fusion volgens vice president en general manager Ramon Pastor moet kunnen concurreren met marktleiders zoals Stratasys en 3D Systems. HP Multi Jet Fusion moet productieve en kwalitatief hoogwaardige 3D printsystemen opleveren die rond de 1 miljoen dollar gaan kosten. Of HP ook aan betaalbare ‘tafelmodellen’ werkt is niet bekend, maar dat zou niemand verbazen als je kijkt naar hoe de HP Deskjet printers de markt voor grotere systemen opengebroken heeft. Multi Jet Fusion is niet de enige 3D printing aankondiging van HP. Het kondigde ook Sprout aan, een iMac-achtig werkstation met ingebouwde 3D scanner en in plaats van en toetsenbord een aanraakgevoelig tekenbord. Voor een kleine 2000 euro krijg je met Sprout een op Windows 8 gebaseerd 3D werkstation uitgerust met alle software om 2D en 3D afbeeldingen te digitaliseren, te bewerken of zelf te tekenen. Sprout is al eind dit jaar beschikbaar en moet de basis vormen van de verovering van de 3D markt in 2016. Of gebruikers daar zo lang op zullen wachten is een vraag die alleen de tijd kan beantwoorden.

Multi Jet Fusion is niet de enige 3D printing aankondiging van HP. Het kondigde ook Sprout aan, een iMac-achtig werkstation met ingebouwde 3D scanner en in plaats van en toetsenbord een aanraakgevoelig tekenbord. Voor een kleine 2000 euro krijg je met Sprout een op Windows 8 gebaseerd 3D werkstation uitgerust met alle software om 2D en 3D afbeeldingen te digitaliseren, te bewerken of zelf te tekenen. Sprout is al eind dit jaar beschikbaar en moet de basis vormen van de verovering van de 3D markt in 2016. Of gebruikers daar zo lang op zullen wachten is een vraag die alleen de tijd kan beantwoorden. Does this sound like an impossible task? Of course it does, but it has to be done if the media industry wants to be able to benchmark and monitor its carbon footprint. We have managed to develop an ISO standard for calculating the carbon footprint of print media (ISO 16759), so now all eyes are on electronic media.

Does this sound like an impossible task? Of course it does, but it has to be done if the media industry wants to be able to benchmark and monitor its carbon footprint. We have managed to develop an ISO standard for calculating the carbon footprint of print media (ISO 16759), so now all eyes are on electronic media.

The idea has been knocking around for a while within Working Group 11 (WG11) of TC130, the ISO technical committee responsible for graphics technology standards. Most of the TC130 work relates to print but some of it, for instance in PDF standards, also relates to electronic communications. The problem is that understanding electronic media’s carbon footprint depends on a different knowledge base that than of print media. It requires understanding of all the stuff related to content that happens in prepress, from content creation to colour management. But it also requires an understanding of networks, servers, archiving, data distribution and of course the devices used to view electronic media.

Quantifying the carbon footprint of all of this is hard, however it can be done if enough brainpower is thrown at the problem. A document is already under development based on the same methodology as ISO 16759. It specifies a consistent method that should provide defensible, trustworthy and above all accurate data. This document is now in the hands of a Joint Working Group (JWG) set up between ISO and the International Electrotechnical Commission’s committee responsible for audio, video and multimedia systems and equipment. The IEC is already working on a quantification methodology for calculating the greenhouse gas emissions of electrical and electronic products and systems. The new JWG combines the expertise of WG11 and IEC members to develop a robust standard for calculating the carbon footprint of electronic media.

It won’t be easy because the document must specify how organisations and end users should define the parameters for calculating the carbon footprint of electronic media. The document will be published as an ISO standard, and will provide specifications for how to calculate the carbon footprint. This includes information about the carbon footprint of the viewing hardware and of the data load associated with a given electronic media product and its use. The creation, publication, distribution, storage, archiving and use of electronic media on any digital device are all to be included. This work is expected to depend on expertise sourced from the electronics and graphic arts industries and to take two years to complete. The timeline is subject to the availability of required expertise for developing the document. Experts specialised in data, server, network and content management, and publishing, are requested to express their interest to participate in this work. Experts are required to attend two one day international meetings per year, plus additional meetings with local experts.

Laurel Brunner

This blog is made possible thanks to: Agfa Graphics (www.agfa.com), Digital Dots (http://digitaldots.org), drupa (www.drupa.com), EFI (www.efi.com), Fespa (www.fespa.com), Heidelberg (www.uk.heidelberg.com), Kodak (www.kodak.com/go/sustainability), Mondi (www.mondigroup.com/products), Pragati Offset (www.pragati.com), Ricoh (www.ricoh.com), Shimizu Printing (www.shzpp.co.jp), Splash PR (www.splashpr.co.uk), Unity Publishing (http://unity-publishing.co.uk) and Xeikon (www.xeikon.com).

Last week I received, among with a small number of others, a very special piece of printing, the first book produced in Europe on the Screen Truepress Jet520HD.

Last week I received, among with a small number of others, a very special piece of printing, the first book produced in Europe on the Screen Truepress Jet520HD.The book, The Journey, documents Nic. Oud´s jrouney to the digital future of printing. It looks like a successful journey and if the digital production printer is operational in November, the company residing in Heerhugowaard, will have a formidable tool to produce fast and affordable digital printing. Just like any other printer would do I first looked at what was wrong with The Journey. The only thing that I could find was the lack of detail in the higher end of the light spectrum in some of the photos and the – very well designed – text could have been a bit blacker for my liking.

What does stand out is the flatness of the pages which have, as happens with digital printing techniques which use too much heat or pressure, held their original shape.

Also the pastel tints in the well photographed Japanese images deserve a compliment. Remains the question: how much does this cost? En can Truepress´s printing compete with normal printing. For Nic. Oud this is perhaps not the most important question. He will use Truepress mainly for hyper personalised content and speed and unlimited possibilities of variable data are much more important than the cost for clients such as Heineken, Makro, Sanoma and T-Mobile.

![]() A lot has been written about the future of the book, but The Economist´s view is unique. Not only the content, but also the packaging is worth studying. It is easy to find your way in the beautifully designed e-book. It has a smooth interface and there is a choice between an ¨old fashioned¨ book, an audio version and a scroll version. Yes, you can only read the book online and cannot copy it, but you can share it via mail or social media as well as comment on it. This great example of what an e-book can look like with well written content should speak to all creative communicators. This is the link to this e-book.

A lot has been written about the future of the book, but The Economist´s view is unique. Not only the content, but also the packaging is worth studying. It is easy to find your way in the beautifully designed e-book. It has a smooth interface and there is a choice between an ¨old fashioned¨ book, an audio version and a scroll version. Yes, you can only read the book online and cannot copy it, but you can share it via mail or social media as well as comment on it. This great example of what an e-book can look like with well written content should speak to all creative communicators. This is the link to this e-book.

Delphax, market leader in check printing, has designed a production printer powered by stationary Memjet inkjet printheads which not only stands out because of its speed but also because of the low investment costs. De Elan 400 processes sheets or rolls of paper from 60 to 350 grammes/m2. The Memjet printheads have 70,400 jets that fire up to 700 million drops of ink per second in CYMK plus 2 spot colours in resolutions up to 1,600×1,600dpl. The maximum paper size for this workhorse is 450x60mm and the maximum format is 441mm. After extensive beta testing the first Elan 400 has been sold to CompuMail Inc, a direct mail company in California.

Delphax, market leader in check printing, has designed a production printer powered by stationary Memjet inkjet printheads which not only stands out because of its speed but also because of the low investment costs. De Elan 400 processes sheets or rolls of paper from 60 to 350 grammes/m2. The Memjet printheads have 70,400 jets that fire up to 700 million drops of ink per second in CYMK plus 2 spot colours in resolutions up to 1,600×1,600dpl. The maximum paper size for this workhorse is 450x60mm and the maximum format is 441mm. After extensive beta testing the first Elan 400 has been sold to CompuMail Inc, a direct mail company in California.

The company that Steve Jobs built began in his parents’ Cupertino house. Watch how that modest beginning grew into world domination.

Lees verder....Lees verder....My first camera was an Agfa Clack, the perfect solution for a complex problem, documenting my memories. During the World Publishing 2014 the producer of ground-breaking products such as the Agfa Focus Desktop Scanner, will introduce a new product which will have the same impact as the Clack, Agfa Graphic´s Eversify. It is a complete cloud-based workflow solution for publishing content to mobile devices. Eversify streamlines the workflow for mobile publishing, from preparing existing content up to and including the sales and distribution. It is suitable for any content management system so the recycling of news can lead to a new income stream for the content provider.

If you are not able to attend the World Publishing 2014 and Eversify´s demonstration, take a look at www.eversify.me. After registration you can download a white paper on mobile publishing.

If there is a sign that digital is the future of printing, it is the cooperation between traditional offset press builders and digital printing systems. Offset still has a lot to offer, high production capacity, ample choice of media and low cost for larger editions, but the announcements that KBA and Heidelberg whoto build, sell and maintain traditional presses will start building digital solutions for specific market segments is a sign of what is to come. For market segments labels, tags and newspapers there is a significant advantage in digital: affordable small editions, variable data and short start up times.

Investments in such solutions will be high and only within reach for financially stable graphic design companies, but there are affordable options for any printer. Those solutions will not have the production capacity of what is being built now, but they will have the print quality that digital is expected to deliver. Many of these solutions will be shown on the Grafische Vakbeurs (Graphic Fair), 5-7 October in Gorinchem. For other solutions we´ll have to wait for the DRUPA 2016. It will then become clear if these solutions are a real threat for the traditional printing techniques.

Never again having to wait for the actual binding of the book which was printed on-demand. This is what the Bourg BB3202 PUR-C binder promises.

Never again having to wait for the actual binding of the book which was printed on-demand. This is what the Bourg BB3202 PUR-C binder promises.

Immediately after printing the binder gathers the pages of books, catalogues or photobooks and produces the end result, all fully automated.

The system can produce books from 100x100mm up to a maximum of 385x320mm, with thickness varying between 1 to 60mm. A barcode system ensures the books get the correct cover.

The maximum capacity of this in-line and off-line solution is 300 books per hour.

De Bourg BB3202 is, as Xerox demonstrates at the Graph Expo, the perfect combination with the iGen 150 digital press. Canon/Océ, HP, Kodak and Konica Minolta production printers can also be used with the Bourg BB3202.

VIGC BOPE 2025: Redefining print. Success in a digital world. Met o.a. Peter Luit als gesprekleider binnen het panelgesprek ‘Platformeconomie, kansen voor grafimedia bedrijven?’

De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK