Rob van den Braak

Following on from a year packed full of successful exhibitions and open houses, Friedheim International will be exhibiting at IPEX 2017 with one of the largest stands at the show, boasting some of the most advanced print finishing equipment on offer today.

Following on from a year packed full of successful exhibitions and open houses, Friedheim International will be exhibiting at IPEX 2017 with one of the largest stands at the show, boasting some of the most advanced print finishing equipment on offer today.

At IPEX 2014 we launched the MBO M80 range of versatile modular folders, at IPEX 2017 Friedheim are proud to present the UK launch of the MBO K80 high speed combination folder, along with the UK launch of the Bograma Servo 550 BASIC short run die-cutter. Joining these two machines will be the KAMA ProFold 74 running over 5000 capacity folders an hour, and Herzog + Heymann creasing line running direct mail work, Komfi’s crown jewel the Sagitta 76 laminator along with the best selling Komfi Amiga 52 with OTF ready to run custom foiling jobs at the show. The line up wraps up with a 78 and a 115 guillotine from Schneider and BaumannWohlenberg respectively and a Zechini Roby Junior 2 compact, semi-automatic case maker.

Although we have predominantly post-press and converting machines at this years show, our full range of equipment and divisions will be represented by all our national sales managers along with their sales specialists. We will be supported by our world class manufacturers with demonstrations and sales presentations running throughout the four day show.

Mark Bristow, Managing Director says: “We decided to go with a much larger stand this year due to the current demand for our equipment. With shorter runs, the requirement for automation, the consolidation of various businesses and the need to be more economical with their work flow, our customers look to us to give them the best advice and best equipment to meet these challenges.”

Friedheim has always enjoyed a rich relationship with IPEX so it was decided to go big this year. Stand 350 is 195m2 and will be a complete production work space, with actual real-world jobs running throughout each day. Format and job changes live on the stand, along with best work practices from Friedheim’s team of experienced technicians and demonstrators.

Stuart Bamford, National Sales Manager – Post-Press says: “IPEX is the perfect venue to launch the MBO K80 folder for the UK market, we did it last time with the M80 and it turned out really well for us, we hope to recapture some of the magic this year too. The K80 is perfectly poised for the UK market, at its price point, there isn’t a faster, more quality folder with this level of automation and advanced control, and the customers we took to the Baumann open house who saw it in June, were truly impressed.”

Lees verder....

[video_embed url=”https://youtu.be/iw9MPZoPqCQ” embed_style=”default” width=”640″]

AR will literally change our world. It will happen because your smartphone is the lens to connect the real and imagined world. MadeWithARkit.com shows how developers build Apple ARKit apps full or AR tricks. From “how does this furniture fit in my home” to a virtual ruler to measure your world. Not all apps are perfect or useful, but when you see what has been built in only a few months after the introducton of ARKit you will understand how the digital world will change because of it.

Lees verder.... Twee uitgaven bewijzen deze zomer dat een tijdschrift een luxe product is geworden, een glossy magazine als eerbetoon aan striptekenaar Jan Kruis en de septemberuitgave van Glamour op superformaat. Twee uitgaven die ongetwijfeld hun weg naar lezers zullen vinden. Lezers die ook nog bereid zijn om voor special drukwerk extra te betalen en van een luxe uitgave een collectors item maken.

Twee uitgaven bewijzen deze zomer dat een tijdschrift een luxe product is geworden, een glossy magazine als eerbetoon aan striptekenaar Jan Kruis en de septemberuitgave van Glamour op superformaat. Twee uitgaven die ongetwijfeld hun weg naar lezers zullen vinden. Lezers die ook nog bereid zijn om voor special drukwerk extra te betalen en van een luxe uitgave een collectors item maken.Lees verder....

Two Dutch magazines prove this summer that magazines have become luxury products. One glossy magazine which is a tribute to cartoonist Jan Kruis and a special super format September issue of Glamour. Two editions which will undoubtedly find their way to the readers. Reader who are willing to pay extra and will make the luxury editions into collectors items. We hope that the sales figures will convince publishers that this is the future of magazines. When creative and graphic print companies get the chance to use finishing technology such as foils there will certainly be a future for pint of this type, which, according to research, also gets the attention of millenials and younger generations.

Two Dutch magazines prove this summer that magazines have become luxury products. One glossy magazine which is a tribute to cartoonist Jan Kruis and a special super format September issue of Glamour. Two editions which will undoubtedly find their way to the readers. Reader who are willing to pay extra and will make the luxury editions into collectors items. We hope that the sales figures will convince publishers that this is the future of magazines. When creative and graphic print companies get the chance to use finishing technology such as foils there will certainly be a future for pint of this type, which, according to research, also gets the attention of millenials and younger generations.

Lees verder....

Print Tech Bangladesh Expo is the largest International technology exhibition for Textile Printing, Screen Printing, Digital Printing, Label Printing, Sublimation printing, Barcode Printing, Press printing, and related printing Machinery Paper, Paper Mill Machinery, Equipment & Accessories

Print Tech Bangladesh Expo is the largest International technology exhibition for Textile Printing, Screen Printing, Digital Printing, Label Printing, Sublimation printing, Barcode Printing, Press printing, and related printing Machinery Paper, Paper Mill Machinery, Equipment & Accessories

4th PRINT TECH BANGLADESH-2018

26-28 JULY 2017, ICCB

ICCB, Kuril, Dhaka, Bangladesh

http://www.limraexpo.com/print/index.html

Print Tech Bangladesh Expo is the leading exhibition for innovative printing, Paper, Paper Mill technology for industrial manufacturing. It is the only event to attended by specialists from the manufactures of Textile printing, Screen printing, Digital printing, label Printing, sublimation printing, finishing equipment, Bar Coding Equipments & Systems, Printing Inks, software, others printing related industry. Print Tech Bangladesh Expo will be a platform for the entire digital print process, Paper, Paper Mill technology suppliers and manufacturers.

Exhibitor Profile: visit this link

Textile & Garment Industry

Textile Printing Machines, Inks, Transfer Papers, Label and package printing machinery, Screen Printing Machines & Manufacturers, Screen Printing Inks, Emulsions, Chemicals, Mesh & Related Materials, Sublimation Transfer Digital Printers, Sublimation Blanks, Inks, Transfer Papers, Machines, Large format, Digital Printers, Digital Inkjet Printing & Printing Consumables, Lamination Machines and Systems.

Direct to Garment Digital Printers, Fabricating & Finishing Equipment.

Glass Printing & Graphic Imaging, Sign Substrates / Equipment, Garment Decoration, Pad printing Machinery & Inks, UV Inks / Machines, Advertising Agencies, Digital Signage, Vehicle Wrapping Solutions, Textile Dyes & Chemicals.

Pre-Press

Automation Workflow Solutions, Computer-to-Plate (CTP) Software & Systems, Colour Management Systems, Design Software, Direct Laser Positive Films, Scanning & Proofing Systems Plate Making Systems, Printing Estimation & Management Software

Press (Printing Presses)

Computer Stationary Printing Machines, Digital Printing Machines, Digital Flex Printing Machines-Wide Format Flexographic Printing Machines, Inkjet Printers, Label Printing Machines, Pad Printing Machines, Print & Apply Systems, Rotogravure Printing Machines, Sheet-Fed Offset Printing Machines, Variable Data Printers, Web Offset Printing Machines.

Print Finishing

Blades & Knives, Book Binding Machines, Cutting & Punching Machines, Decorating Equipments, Die-cutting Machines & Equipments, Dies, Embossing Machines, Folding Machines, Gluing & Laminating Machines.

Hard Case Making Machines, Hot Melt Adhesive Coater, Paper & Board Creasing Machines, Perfect Binding Machines, Photo Glazing Machines, Pinning & Sewing Machines, Slitting & Rewinding Machines, UV Coating Machines & Equipments, Wire Stitching Machines.

Ancillary Equipments & Products

Dies, Bar Coding Equipments & Systems, RFID Systems, Anti Counterfeiting, Technology & Products, Clutches & Brakes, Spares, Printing Accessories & Consumables, Printing Inks, Printing Plates & Blankets, Solvents & Varnishes, Adhesives & Chemicals, Rubber Rollers & Printing Rollers.

Paper, Paper Making Machinery, Equipment & Accessories

Automation & Instrumentation, Bearing & Accessories, Boilers & Turbines, Complete Paper Mill Machinery, Converting Machinery, Chemical recovery Plant & equipment, De-Inking recycled fiber technology, Dewatering Elements, Industrial Rolls, Industrial Gears, Knives, Blades & Holders, Heaters &, Heating Equipment, Machinery, Spares & Accessories, Paper Machine Clothing, Packaging Machinery & Materials, Printing Machinery, Pumps, Valves & Systems, Pollution Control Equipment’s, Quality Control Equipment’s, Stock Preparation and Equipment, Testing Equipment’s, Tissue Machinery, Technology & Machinery Suppliers, Transport & Material Handling, Used Paper Machinery & Equipment’s, Waste Water treatment, Kraft Paper, Handmade Paper, Handmade Paper Products, Newsprint Paper, Paper Boards, Paper Products, Specialty Paper, Tissue Paper, Tissue Paper Products, Writing Paper & Printing Paper, Fiber, Minerals, Pigments, Pulp, Specialty Chemicals, Waste Paper, Green Field Projects, Pollution Control Equipment’s, Finance & Investment, Publicity & Branding, Research & Development, Skilled Manpower.

Lees verder....

This week´s Verdigris blog by Laurel Brunner focuses on the RE100 initiative. RE100 is a growing group of companies that want to use only renewable energy. Laurel´s blog shows how difficult it is to get to a 100% and why smaller companies should support this initiative. Read her blog via this link on our articles page.

This week´s Verdigris blog by Laurel Brunner focuses on the RE100 initiative. RE100 is a growing group of companies that want to use only renewable energy. Laurel´s blog shows how difficult it is to get to a 100% and why smaller companies should support this initiative. Read her blog via this link on our articles page.

Lees verder....

In haar Verdigris Blog deze week breekt Laurel Brunner een lans voor het RE100 initiatief. RE100 is een groeiende groep bedrijven die alleen duurzame energie willen gebruiken. Hoe moeilijk het is om de 100% te bereiken en waarom ook kleinere bedrijven dit initiatief zouden moeten ondersteunen, lees je in Laurel’s blog via deze link naar onze artikelenpagina.

In haar Verdigris Blog deze week breekt Laurel Brunner een lans voor het RE100 initiatief. RE100 is een groeiende groep bedrijven die alleen duurzame energie willen gebruiken. Hoe moeilijk het is om de 100% te bereiken en waarom ook kleinere bedrijven dit initiatief zouden moeten ondersteunen, lees je in Laurel’s blog via deze link naar onze artikelenpagina.Lees verder....

Bookprinter Print Group installs first Screen Truepress Jet520HD inkjet press with SC inks

Print Group, the leading digital book printer in Poland, has installed a Screen Truepress Jet520HD high-speed roll-fed inkjet press with Screen’s new SC inks at its Booksfactory site in Szczecin. The addition will enhance turnaround times for full colour high-definition book printing, as well as allowing the business to take on larger volumes as customer demand grows. Print Group has long been committed to digital book production, and previously installed the first Screen Truepress Jet 520EX Mono in Europe for black and white production in 2013. Print Group is also the first company to invest in the 520HD with SC ink.

Print Group, the leading digital book printer in Poland, has installed a Screen Truepress Jet520HD high-speed roll-fed inkjet press with Screen’s new SC inks at its Booksfactory site in Szczecin. The addition will enhance turnaround times for full colour high-definition book printing, as well as allowing the business to take on larger volumes as customer demand grows. Print Group has long been committed to digital book production, and previously installed the first Screen Truepress Jet 520EX Mono in Europe for black and white production in 2013. Print Group is also the first company to invest in the 520HD with SC ink.

Launched at Hunkeler Innovation Days 2017 to wide acclaim, Screen’s new versatile inkjet SC inks will enable Print Group to leverage the benefits of inkjet whilst continuing to use their existing standard uncoated papers. The innovative SC inks do not require any pre-treatment or post coating, enabling printing on coated papers as well. The inks are currently available only on the Truepress Jet520HD press.

“Print Group sees digital inkjet printing as the way forward for book production,” comments Walter Wanat, International Sales Director for the Print Group. “Printed book sales are growing healthily, and as our customers grow, Print Group must also grow. As part of a whole new book factory facility to help meet that rising demand, we added the Screen Truepress Jet520HD to increase our capacity for larger numbers and volumes of colour print runs.

“From our previous experience with the technology, Screen was always going to be at the top of our list when we came to make another investment. The SC inks combined with the Jet520HD however made it a very easy decision. The quality is remarkable and the range of substrates provides great benefits to my customers.”

The Screen Truepress Jet520HD is a high-definition inkjet web press with a true print resolution of 1,200 dpi and precise droplet size control at up to 150 metres per minute. The Truepress Jet520HD achieves the colours, textures, details and solid ink areas expected for high-end publication and commercial work.

“This press delivers quality close to offset and high production efficiency, meaning a more competitive service for our customers across Europe,” says Wanat, “At the same time, book consumers expect more for their money, so quality is important to our customers. With the Screen Truepress, we can produce high definition print for larger print runs, whilst still using digital print production.”

Screen Sales Manager Patrick Jud, concludes, “The superior speed, quality and production costs delivered by the Screen Truepress Jet520HD makes it extremely attractive to book printers. We’re delighted to be working with Print Group again and are excited to see what they produce.”

Xitrons software will drive new digital label presses and Flexo/Resin/Thermal CTP Device

Xitron, the leading independent developer of RIP and workflow products for commercial, digital, and high-speed inkjet printing has announced an agreement with Liaoning Basch Digital for the development of a cross-product prepress workflow. The system will be designed for Basch’s Panthera® 3322C color inkjet label press, the 3326V digital inkjet varnish press, and will also be capable of driving the Panthera® CTP line.

Xitron, the leading independent developer of RIP and workflow products for commercial, digital, and high-speed inkjet printing has announced an agreement with Liaoning Basch Digital for the development of a cross-product prepress workflow. The system will be designed for Basch’s Panthera® 3322C color inkjet label press, the 3326V digital inkjet varnish press, and will also be capable of driving the Panthera® CTP line.

The Panthera® 3322C uses the Memjet Sirius inkjet head and is capable of print speeds up to 18 meters per minute with a maximum web width of 330mm. Xitron’s Northstar RIP and workflow will handle job submission, job tracking, spot color matching, label-based step-and-repeat, and variable data input, driving the press at full rated speed.

“We’re extremely pleased to partner with Basch on this project,” commented Karen Crews, President of Xitron. “Our experience with other Memjet OEMs places us ahead of the curve in development of these systems, so time-to-market will be short. Of equal benefit is our background with commercial offset and flexographic CTP devices,” she added, “which will allow us to bring a full-featured workflow to Basch’s Panthera® CTP line as well.”

Designed to image flexographic, resin, and metal printing plates, the Panthera® 500G offers resolutions up to 4,000 dpi with a maximum plate size of 670mm x 640mm. It’s capable of imaging plates at speeds up to three square meters per hour and it features an auto-focusing system, which matches the laser energy with drum speed and the plate material being used. “We chose Xitron as our workflow partner because of their ability to offer a complete solution,” said Mr. Du Xuan, GM of Liaoning Basch. “Instead of supporting several separate systems based on output type, we are able to collapse to a single architecture that includes the features necessary for high-speed, color-accurate throughput regardless of destination.”

Basch demonstrated the Panthera® 3322C this past May during ChinaPrint 17 in Beijing. They will also be exhibiting at LabelExpo Asia in Shanghai beginning December 5th, where Xitron’s Northstar workflow will be driving multiple devices.

Print Group, the leading digital book printer in Poland, has installed a Screen Truepress Jet520HD high-speed roll-fed inkjet press with Screen’s new SC inks at its Booksfactory site in Szczecin. The addition will enhance turnaround times for full colour high-definition book printing, as well as allowing the business to take on larger volumes as customer demand grows. Print Group has long been committed to digital book production, and previously installed the first Screen Truepress Jet 520EX Mono in Europe for black and white production in 2013. Print Group is also the first company to invest in the 520HD with SC ink.

Print Group, the leading digital book printer in Poland, has installed a Screen Truepress Jet520HD high-speed roll-fed inkjet press with Screen’s new SC inks at its Booksfactory site in Szczecin. The addition will enhance turnaround times for full colour high-definition book printing, as well as allowing the business to take on larger volumes as customer demand grows. Print Group has long been committed to digital book production, and previously installed the first Screen Truepress Jet 520EX Mono in Europe for black and white production in 2013. Print Group is also the first company to invest in the 520HD with SC ink.

Launched at Hunkeler Innovation Days 2017 to wide acclaim, Screen’s new versatile inkjet SC inks will enable Print Group to leverage the benefits of inkjet whilst continuing to use their existing standard uncoated papers. The innovative SC inks do not require any pre-treatment or post coating, enabling printing on coated papers as well. The inks are currently available only on the Truepress Jet520HD press.

“Print Group sees digital inkjet printing as the way forward for book production,” comments Walter Wanat, International Sales Director for the Print Group. “Printed book sales are growing healthily, and as our customers grow, Print Group must also grow. As part of a whole new book factory facility to help meet that rising demand, we added the Screen Truepress Jet520HD to increase our capacity for larger numbers and volumes of colour print runs.

“From our previous experience with the technology, Screen was always going to be at the top of our list when we came to make another investment. The SC inks combined with the Jet520HD however made it a very easy decision. The quality is remarkable and the range of substrates provides great benefits to my customers.”

The Screen Truepress Jet520HD is a high-definition inkjet web press with a true print resolution of 1,200 dpi and precise droplet size control at up to 150 metres per minute. The Truepress Jet520HD achieves the colours, textures, details and solid ink areas expected for high-end publication and commercial work.

“This press delivers quality close to offset and high production efficiency, meaning a more competitive service for our customers across Europe,” says Wanat, “At the same time, book consumers expect more for their money, so quality is important to our customers. With the Screen Truepress, we can produce high definition print for larger print runs, whilst still using digital print production.”

Screen Sales Manager Patrick Jud, concludes, “The superior speed, quality and production costs delivered by the Screen Truepress Jet520HD makes it extremely attractive to book printers. We’re delighted to be working with Print Group again and are excited to see what they produce.”

Lees verder.... Op Labelexpo 2017 kunnen bezoekers voor het eerst kennismaken met de nieuwe HYBRID technologie op de HYBRID Lamination Coating Line van Maan Engineering, een coating line waarop zowel laminaat als linerless labels geproduceerd kunnen worden. Deze unieke HYBRID coating technologie staat symbool voor de innovatieve kracht van het Nederlandse bedrijf Maan Engineering.

Op Labelexpo 2017 kunnen bezoekers voor het eerst kennismaken met de nieuwe HYBRID technologie op de HYBRID Lamination Coating Line van Maan Engineering, een coating line waarop zowel laminaat als linerless labels geproduceerd kunnen worden. Deze unieke HYBRID coating technologie staat symbool voor de innovatieve kracht van het Nederlandse bedrijf Maan Engineering.

Slimme technologie

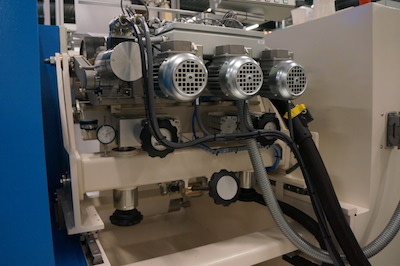

De nieuwe technologie van Maan Engineering wordt toegepast in het Hotmelt Coating Station, dat samen met het Silicone Coating Station het hart vormt van het “Maan” assortiment. De basis van de HYBRID technologie is, dat bij de omschakeling van laminaat naar linerless het Hotmelt Coating Station geroteerd wordt. Zo kan aan beide zijden van de papier- of foliebaan met hotmelt gecoat worden. Dat betekent concreet dat het station niet alleen voor laminaat, maar ook voor linerless kan worden ingezet. En dat bij een omsteltijd slechts 15 minuten!

Linerless binnen handbereik

De HYBRID technologie biedt labeldrukkers talloze nieuwe mogelijkheden. Door verschillende coating en converting technieken in één lijn te zetten en zelf de lijm en silicone aan te brengen, kunnen zij speciale laminaten maken die hen onderscheiden van de concurrent. Onderzoek heeft bovendien uitgewezen, dat het voor drukkerijen lucratief is hun eigen laminaat te produceren. Bovendien brengt de HYBRID technologie de relatief kleine linerless markt voor iedere labeldrukker binnen handbereik. Zo bezorgt de hybride technologie labeldrukkers een enorme voorsprong op de markt.

Over Maan Engineering

Maan Engineering is trotse deelnemer aan de Linerless Trail tijdens LabelExpo 2017.

Maan Engineering B.V. ontwikkelt en produceert innovatieve release en adhesive coating equipment voor de wereldwijde label printing industry. De slimme oplossingen van “Maan” dragen bij aan het onderscheidend vermogen en de productiviteit van labeldrukkerijen. Ze bieden volop kansen om eigen coating technieken toe te passen, en maken de productie mogelijk van eigen laminaatmateriaal en speciale labels, zoals: linerless labels, clear-2-clear labels, multilayer etiketten en bandenetiketten.

De nieuwe HYBRID Lamination Coating Line van Maan Engineering wordt tijdens de Labelexpo 2017 gepresenteerd op stand 7D23.

Lees verder....De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK