Rob van den Braak

At Labelexpo 2017, visitors will be able to acquaint themselves for the first time with the new HYBRID technology in Maan Engineering’s HYBRID Lamination Coating Line, a coating line that allows you to produce both laminate and linerless labels. This unique HYBRID coating technology symbolizes the innovative power of the Dutch company Maan Engineering.

At Labelexpo 2017, visitors will be able to acquaint themselves for the first time with the new HYBRID technology in Maan Engineering’s HYBRID Lamination Coating Line, a coating line that allows you to produce both laminate and linerless labels. This unique HYBRID coating technology symbolizes the innovative power of the Dutch company Maan Engineering.

Smart technology

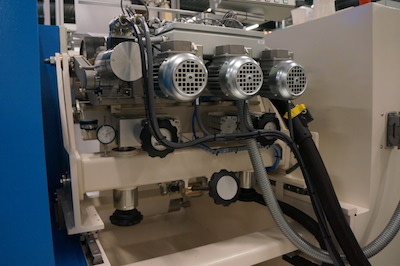

Maan Engineering’s new technology is used in the Hotmelt Coating Station which, together with the Silicone Coating Station, comprises the core of the Maan range. The basis of the HYBRID technology is that, when switching from laminate to linerless, the Hotmelt Coating Station is rotated. In this way, both sides of the paper or foil strip can be coated with hotmelt, meaning that the station can be used not only for laminate, but also for linerless. And the switch takes just 15 minutes!

Linerless within reach

The HYBRID technology offers label printers numerous new possibilities. Using different coating and converting techniques in a single line and applying the adhesive and silicone themselves, they can make special laminates that distinguish them from their competitors. Besides, research has demonstrated that it is lucrative for printers to produce their own laminate. Furthermore the HYBRID technology makes the relatively small linerless market accessible to every label printer. As a result, the hybrid technology gives label printers a massive competitive lead in the market.

About Maan Engineering

Maan Engineering B.V. develops and produces innovative release and adhesive coating equipment for the worldwide label printing industry. Maan’s smart solutions contribute to the ability of label printers to distinguish themselves from the competition, at the same time increasing productivity. The equipment offers a huge range of options for using in-house coating techniques, enabling the production of proprietary laminate materials and special labels, such as linerless labels, clear-2-clear labels, multilayer labels and tyre labels.

Maan Engineering’s new HYBRID Lamination Coating Line will be presented during Labelexpo 2017 at stand 7D23.

Lees verder.... Xitron, the leading independent developer of RIP and workflow products for commercial, digital, and high-speed inkjet printing has announced that envelope press products from two of their OEM partners have been selected as “Must See ‘Em” award winners at Print 17. The industry’s top vendors compete for the recognition by submitting their best products for evaluation prior to the fall printing show.

Xitron, the leading independent developer of RIP and workflow products for commercial, digital, and high-speed inkjet printing has announced that envelope press products from two of their OEM partners have been selected as “Must See ‘Em” award winners at Print 17. The industry’s top vendors compete for the recognition by submitting their best products for evaluation prior to the fall printing show.

This year, products from Printware and W+D were chosen in the Imprinting, Mailing, Shipping and Fulfillment category. Both envelope presses feature Xitron’s Navigator workflow with easy-to-use spot color matching, and both will be demonstrated on the show floor at Print 17 in Chicago beginning September 10th.

“With Printware, W+D, and our other Memjet OEM’s, our goal is to provide a simple solution to the common problem of inaccurate color reproduction,” said Jeffrey Piestrak, Xitron Product Manager. “We view these accolades as evidence of our success in the high-speed inkjet market and congratulate them on their awards.”

Exhibiting in booth 2463, Printware’s new iJetColorPro will make its show debut, printing full color envelopes at speeds up to 7,120 per hour. The Navigator Northstar-based workflow provides a powerful option for customers who need robust color management and variable data elements in each piece. “We’ve incorporated this new user interface with an easy to use touch screen monitor,” said Tim Murphy, President of Printware.

W+D (booth 1248) will be demonstrating the world’s fastest production class digital inkjet envelope press, capable of printing 32,000 #10 envelopes per hour at 1600 x 1375 dpi. W+D’s digital front end is based on Xitron’s high-speed version of the Navigator workflow, delivering super accurate color while keeping up with the press’ phenomenal speed, even when variable data is present.

“The Xitron spot color matching technology is a critical element of our success with trade shop envelope and commercial direct mail printers who print on standard white wove paper envelopes,” said Andrew Schipke, Vice President-Sales and Marketing for W+D North America.”

Xitron inkjet workflows will also be driving other Memjet-based presses at the show, including those from Colordyne (3349), Neopost (2007), and others.

Lees verder.... Organiser Frazer Chesterman of tradeshow Pure Digital, which will take place in Amsterdam next April, has an interesting vision on the function of print. In his column he says that people experience an overload of information which gives print an increasingly important role.

Organiser Frazer Chesterman of tradeshow Pure Digital, which will take place in Amsterdam next April, has an interesting vision on the function of print. In his column he says that people experience an overload of information which gives print an increasingly important role.

Read his column here:

Fraser Chesterman – Print fills the hole

It wasn’t so long ago that your TV only had 4 or 5 channels and your phone was for making calls with. However, now we are constantly bombarded by an information overload. How can print survive in this crazy new environment?

Put yourself in the shoes of a consumer right now. Just for a second. Imagine that it’s the 1950s. You consume as much content as you can. You likely frequent your local library. Perhaps you listen to the radio and watch the nightly news on TV. Maybe you also subscribe to, and read the entire, daily newspaper. Maybe your household receives a few magazines every month. That’s about it. There really isn’t a big difference between the information you know is available and the information you can consume.

Now, fast forward to 2017. You live in a 200-channel television universe, there are multiple daily metropolitan newspapers, apps, mobile phones, Instagram, Facebook, Google and the technology is exploding. Suddenly, there is far more content created than you can consume.

So, what do I think has happened? I can certainly consume more content than I could two decades ago, but no matter how much content is available, I can’t consume much more. And relative to the sheer volume of content available to me, I’m actually consuming a smaller percentage every day.

Now, put on your Marketer Hat or your Content Creator Hat again and take a look at the Information Overload chart above. The bottom line represents the consumer’s ability to consume more content. Yes, it’s gone up – but only ever-so-slightly.

Now look at the top line (the information available). It’s sky-rocketing and shows no signs of slowing down. The consumer stands no chance of consuming much more of that wonderful content you’re creating than they could yesterday or they will tomorrow.

The gap between the two is the perceived opportunity gap. Marketers are trying to squeeze information about their products in the gap.

The biggest opportunity today is to be part of the information that people can consume and not in the area of overload – the Actual opportunity GAP.

I believe there is tremendous opportunity for Print to fit in the gap. This is all about creating quality content over quantity.

So think about how to use all the digital content that is being created to elevate content to print – elevate shortlived digital successes to high quality printed products, extending the digital life span and reap the rewards for four to six weeks.

It also means we need to define our roles in this ever-growing world of content creation. In my opinion, this is why we see a huge interest in content curation over content creation. It represents the desire of the consumer to filter out the noise and get straight to relevant, high-quality content, given the limitations on their ability to consume.

So, where’s the opportunity? Content curation is certainly one avenue to pursue. Anytime you can help your audience find the best content, more efficiently, more often, you’re building trust.

However, in order to be successful at this, your brand must be perceived as a completely objective brand in the marketplace. Otherwise, your consumer has to find multiple curators and still consume more content to ensure they get the ‘whole picture.’ The content curation model is really designed to help consumers more efficiently find relevant content, not necessarily the bestcontent.

The real opportunity here, in my opinion, is to create – and curate – the best content focused on one specific area frequently enough that you become the one brand that consumers look to for this information. It’s the opportunity of proving your brand is capable of creating and disseminating that content across media in a wide variety of formats.

So when it comes to creating the printed product then this becomes the opportunity to draw together the good stuff out there, disseminate and deliver something of value that is easy to consume.

If you’re just creating content for the sake of creating content, you’re not helping your consumers – you’re overwhelming them.

Thanks to paperkitecreative for the image Digital v Print.

(The graph in the blog credit to Andrew Davis of Monumental shift)

Returning IPEX exhibitor Col-Tec to present latest ‘Smart Collator’ machine with IDC Software

Having first attended IPEX in 1980 and not missed a single show since, exhibitor Col-Tec (Collating Technology), is set to return to IPEX this year to present one of its latest products. Reflecting on previous successes at IPEX exhibitions, market leader Col-Tec is looking forward to similar activities in 2017, discussing collating technology, manufacturing and solutions, as well as interacting with customers and its worldwide distributor network.

Col-Tec will be presenting and operating its latest smart collating ‘Signature Machine’, equipped with its innovative Intelligent Data Collating (IDC) Software. Unlike typical collating applications where the collated set is repeated numerous times, IDC delivers versatility at the press of a button, by allowing many different patterns and combinations of sets to follow each other.

The machine is known to have a number of other key features that will be of interest to many printers attending the show. The product includes deep pile feeding and ultra sonic detectors. Since 1975, Col-Tec has been at the forefront in the manufacture of horizontal suction feed collators.

Col-Tec’s Paul Bailey commented: “Showing off our fantastic equipment is important to us, and therefore demonstrating the benefits of the IDC software in our largest target market on our stand at IPEX will give us the opportunity to do so.”

IPEX is the UK’s longest running international print show. The event takes place from 31st October to 3rd November 2017 at the NEC in Birmingham. IPEX 2017 will be a showcase of innovation, technology and print in action, covering a range of applications including printing, software, digital, and finishing.

Online visitor registration is open and IPEX is free to attend, visitors are advised to register early to avoid the queues and take advantage of travel discounts and event updates.

Online drukkerij ZoGedrukt.nl biedt de klant de mogelijkheid om direct een totaalprijs te berekenen voor een specifieke digitale drukopdracht. Met de ontwikkeling van de unieke tool PrintCalc kan een digitale drukopdracht direct worden berekend. Hiermee onderscheidt de drukker uit Oldenzaal zich van de overige online drukkers, en biedt hiermee nog meer service aan klanten.

Online drukkerij ZoGedrukt.nl biedt de klant de mogelijkheid om direct een totaalprijs te berekenen voor een specifieke digitale drukopdracht. Met de ontwikkeling van de unieke tool PrintCalc kan een digitale drukopdracht direct worden berekend. Hiermee onderscheidt de drukker uit Oldenzaal zich van de overige online drukkers, en biedt hiermee nog meer service aan klanten.

Wat is de PrintCalc?

De PrintCalc is een slimme prijscalculator die direct, aan de hand van de door de klant gekozen kenmerken, de prijs van digitaal drukwerk berekend. In tegenstelling tot de collega drukkerijen beperkt ZoGedrukt.nl zich niet alleen tot het formaat, afwerking en aantal, maar gaat zij juist nog een stap verder. Alle specificaties zoals bijvoorbeeld: het stansen, rillen, vouwen en perforatie kunnen nu direct worden berekend. “Door continue in contact te staan met onze klanten, viel het ons op dat er erg veel frustratie en onduidelijkheid was op het gebied van prijscalculatie. Zodoende zijn wij aan de slag gegaan en hebben we de PrintCalc ontwikkeld”, aldus Maikel Slot, de oprichter van het bedrijf.

Hoe werkt het?

ZoGedrukt geeft op de website duidelijk aan welke specificaties geselecteerd kunnen worden.

Omdat dit per product verschilt, is nauwkeurigheid geboden. Voor digitaal drukwerk kan men diverse afwerkingen, formaten en andere mogelijkheden selecteren. “De PrintCalc berekent de exacte prijs direct. Je kunt het daarna direct bestellen zonder dat je hoeft te wachten op offertes en er handmatig nog een order moet worden aangemaakt”, zegt Maikel Slot, eigenaar van ZoGedrukt.nl.

Breed assortiment

Naast deze unieke innovatie biedt ZoGedrukt.nl een breed assortiment aan drukwerk. Om tegemoet te komen aan de wensen van klanten gebruikt men de nieuwste productietechnieken, efficiënte logistiek en een slim voorraadbeleid, zodat men altijd snel kan leveren. Met de HP Indigo 7.000 series en de HP Indigo 10.000 worden niet alleen flyers en folders, maar bijvoorbeeld ook posters, (oblong) brochures of offertemappen binnen 1 dag digitaal gedrukt en afgeleverd, zowel in Nederland als België.

PrintCalc gebruiken

De tool is te vinden op de website van ZoGedrukt of direct via www.printcalc.nl.

Having first attended IPEX in 1980 and not missed a single show since, exhibitor Col-Tec (Collating Technology), is set to return to IPEX this year to present one of its latest products. Reflecting on previous successes at IPEX exhibitions, market leader Col-Tec is looking forward to similar activities in 2017, discussing collating technology, manufacturing and solutions, as well as interacting with customers and its worldwide distributor network.

Having first attended IPEX in 1980 and not missed a single show since, exhibitor Col-Tec (Collating Technology), is set to return to IPEX this year to present one of its latest products. Reflecting on previous successes at IPEX exhibitions, market leader Col-Tec is looking forward to similar activities in 2017, discussing collating technology, manufacturing and solutions, as well as interacting with customers and its worldwide distributor network.

Col-Tec will be presenting and operating its latest smart collating ‘Signature Machine’, equipped with its innovative Intelligent Data Collating (IDC) Software. Unlike typical collating applications where the collated set is repeated numerous times, IDC delivers versatility at the press of a button, by allowing many different patterns and combinations of sets to follow each other.

The machine is known to have a number of other key features that will be of interest to many printers attending the show. The product includes deep pile feeding and ultra sonic detectors. Since 1975, Col-Tec has been at the forefront in the manufacture of horizontal suction feed collators.

Col-Tec’s Paul Bailey commented: “Showing off our fantastic equipment is important to us, and therefore demonstrating the benefits of the IDC software in our largest target market on our stand at IPEX will give us the opportunity to do so.”

IPEX is the UK’s longest running international print show. The event takes place from 31st October to 3rd November 2017 at the NEC in Birmingham. IPEX 2017 will be a showcase of innovation, technology and print in action, covering a range of applications including printing, software, digital, and finishing. Online visitor registration is open and IPEX is free to attend, visitors are advised to register early to avoid the queues and take advantage of travel discounts and event updates.

Lees verder.... The international label organisation FINAT proudly announced the 25th Labelexpo. This year the tradeshow will bring introductions by Mimaki, Fujifilm Primera and many others, and enjoys growing interest from this vertical market segment. The growth is not just because of the increasing digitisation of label printing, but also because of new and efficient flex solutions and hybrid systems that produce faster and more cost efficient.

The international label organisation FINAT proudly announced the 25th Labelexpo. This year the tradeshow will bring introductions by Mimaki, Fujifilm Primera and many others, and enjoys growing interest from this vertical market segment. The growth is not just because of the increasing digitisation of label printing, but also because of new and efficient flex solutions and hybrid systems that produce faster and more cost efficient.

Read more about this anniversary in the press release below.

The flag bearers of the European label industry — the international label association FINAT and Labelexpo Europe founders Tarsus Ltd — are celebrating the 25th anniversary of their partnership this year at the biggest-ever Labelexpo show, taking place at the Brussels Expo, 25-28 September.

An industry initiative

At the heart of their present co-operation is the establishment of the Labelexpo Advisory Board (‘LAB’), composed of representatives from Labelexpo organisers Tarsus, FINAT board members, and show exhibitors. In an industry that is continually growing and changing, the LAB’s key mission has been, and continues to be, to expand the event’s profile to include all the ‘new technologies’ that now form part of the definition of a ‘label’; and to make both exhibiting and participation in the associated events programme a truly special experience. Their efforts, coupled with the first results of long-term investment by the event venue, will deliver improvements in logistics, facility management, and visitor convenience for this year’s show, which features an awe-inspiring total of 700-plus exhibitors from more than 40 countries around the world.

On-site events

The show itself is enhanced by a lively agenda of on-site workshops, seminars, and, of course, the presentation dinner at which this year’s Global Label Industry Awards will be presented.

FINAT will be welcoming members, as well as potential association members, to their stand, 11A31, for refreshments, and to preview the new base of advanced online features which the members-only website offers today, along with their strong year-round events programme. This includes a series of webinars; FINAT’s biennial Technical Seminar next March, updating members on the state of the art of self-adhesive technology along the supply chain; its major annual opinion-leading event for senior managers, the European Label Forum in June; and, for young managers in the label industry’s many and varied disciplines, the lively Young Managers Club Congress, taking place later in 2018.

European Digital Label Study

Labelexpo Europe will also be the launch platform for FINAT’s Digital Label Study, an authoritative report, commissioned from LPC – specialised in research, technical PR, and commercial due diligence within the printing and packaging industries – which will offer a critical analysis of the current digital label printing technology landscape in Europe, as well as identifying trends and future projections relevant to digital label print across different regions and sectors. The report is based on a survey conducted with more than 100 label companies across Europe, who were asked questions on topics ranging from the profitability of their digital presses; their most significant challenges associated with digital label production; and the opportunities they see for digital label printing in the near and longer-term future.

‘Young Talent’ initiative

FINAT will also present an update on the important topic of attracting ‘young talent’ to the labels and package printing industry. At the beginning of this year, FINAT launched an initiative, together with the German label association VskE and other national associations, with the objective of developing an industry campaign that can be instrumental in attracting the ‘next generation’ workforce for the label industry across Europe.

Recycling awareness

A special feature on FINAT’s stand will, once again, be the Recycling Desk, at which visitors can obtain information about the various recycling solutions for spent release liner, and where a special video will be launched to promote awareness among both users and manufacturers of labels concerning the necessity, and benefits of, secondary uses for spent liners.

Visions of (future) labelling

On display on the FINAT stand will be the winning entries in this year’s prestigious FINAT Label Competition. Not only are these labels the best in their class, but what is equally interesting are the stories behind their success. FINAT will present a series of video-recorded interviews with the winning companies in the main category groupings, to provide a source of inspiration for continuous improvement and innovation which will be rewarded in future editions of the competition.

The Label Academy

FINAT will also be encouraging participation in Tarsus’ growing Label Academy initiative – providing label and packaging industry technical training online in topic-specific modules, with the opportunity for students to acquire technical certification for each successfully completed module. Today, Label Academy certification is accepted around the world as a valuable, ‘industry standard’ qualification.

‘A must-attend event’

Comments FINAT Managing Director Jules Lejeune: ‘For all concerned in the label and product decoration value chain, from raw material supplier to brand owner and retailer, Labelexpo Europe 2017 is a must-attend event’.

Lees verder....

De internationale labelorganisatie FINAT kondigt met trots de 25ste Labelexpo aan. Een vakbeurs die zich dit jaar niet alleen mag verheugen in primeurs van Mimaki, Fujifilm Primera en andere bedrijven, maar ook in een groeiende belangstelling voor dit verticale marktsegment. Een groei die niet alleen komt door de digitalisering van het labelprinten, maar ook van nieuwe efficiënte flexo- oplossingen en hybride systemen, die grotere oplagen sneller en tegen een lagere kostprijs kunnen produceren.

De internationale labelorganisatie FINAT kondigt met trots de 25ste Labelexpo aan. Een vakbeurs die zich dit jaar niet alleen mag verheugen in primeurs van Mimaki, Fujifilm Primera en andere bedrijven, maar ook in een groeiende belangstelling voor dit verticale marktsegment. Een groei die niet alleen komt door de digitalisering van het labelprinten, maar ook van nieuwe efficiënte flexo- oplossingen en hybride systemen, die grotere oplagen sneller en tegen een lagere kostprijs kunnen produceren.

The flag bearers of the European label industry — the international label association FINAT and Labelexpo Europe founders Tarsus Ltd — are celebrating the 25th anniversary of their partnership this year at the biggest-ever Labelexpo show, taking place at the Brussels Expo, 25-28 September.

An industry initiative

At the heart of their present co-operation is the establishment of the Labelexpo Advisory Board (‘LAB’), composed of representatives from Labelexpo organisers Tarsus, FINAT board members, and show exhibitors. In an industry that is continually growing and changing, the LAB’s key mission has been, and continues to be, to expand the event’s profile to include all the ‘new technologies’ that now form part of the definition of a ‘label’; and to make both exhibiting and participation in the associated events programme a truly special experience. Their efforts, coupled with the first results of long-term investment by the event venue, will deliver improvements in logistics, facility management, and visitor convenience for this year’s show, which features an awe-inspiring total of 700-plus exhibitors from more than 40 countries around the world.

On-site events

The show itself is enhanced by a lively agenda of on-site workshops, seminars, and, of course, the presentation dinner at which this year’s Global Label Industry Awards will be presented.

FINAT will be welcoming members, as well as potential association members, to their stand, 11A31, for refreshments, and to preview the new base of advanced online features which the members-only website offers today, along with their strong year-round events programme. This includes a series of webinars; FINAT’s biennial Technical Seminar next March, updating members on the state of the art of self-adhesive technology along the supply chain; its major annual opinion-leading event for senior managers, the European Label Forum in June; and, for young managers in the label industry’s many and varied disciplines, the lively Young Managers Club Congress, taking place later in 2018.

European Digital Label Study

Labelexpo Europe will also be the launch platform for FINAT’s Digital Label Study, an authoritative report, commissioned from LPC – specialised in research, technical PR, and commercial due diligence within the printing and packaging industries – which will offer a critical analysis of the current digital label printing technology landscape in Europe, as well as identifying trends and future projections relevant to digital label print across different regions and sectors. The report is based on a survey conducted with more than 100 label companies across Europe, who were asked questions on topics ranging from the profitability of their digital presses; their most significant challenges associated with digital label production; and the opportunities they see for digital label printing in the near and longer-term future.

‘Young Talent’ initiative

FINAT will also present an update on the important topic of attracting ‘young talent’ to the labels and package printing industry. At the beginning of this year, FINAT launched an initiative, together with the German label association VskE and other national associations, with the objective of developing an industry campaign that can be instrumental in attracting the ‘next generation’ workforce for the label industry across Europe.

Recycling awareness

A special feature on FINAT’s stand will, once again, be the Recycling Desk, at which visitors can obtain information about the various recycling solutions for spent release liner, and where a special video will be launched to promote awareness among both users and manufacturers of labels concerning the necessity, and benefits of, secondary uses for spent liners.

Visions of (future) labelling

On display on the FINAT stand will be the winning entries in this year’s prestigious FINAT Label Competition. Not only are these labels the best in their class, but what is equally interesting are the stories behind their success. FINAT will present a series of video-recorded interviews with the winning companies in the main category groupings, to provide a source of inspiration for continuous improvement and innovation which will be rewarded in future editions of the competition.

The Label Academy

FINAT will also be encouraging participation in Tarsus’ growing Label Academy initiative – providing label and packaging industry technical training online in topic-specific modules, with the opportunity for students to acquire technical certification for each successfully completed module. Today, Label Academy certification is accepted around the world as a valuable, ‘industry standard’ qualification.

‘A must-attend event’

Comments FINAT Managing Director Jules Lejeune: “For all concerned in the label and product decoration value chain, from raw material supplier to brand owner and retailer, Labelexpo Europe 2017 is a must-attend event.”

Lees verder....

Starting your own environmental certification is, as Laurel Brunner describes in her Verdigris blog, a simple way to avoid adhering to ISO XXX standards. She uses the “Cradle to Cradle” example to debunk a number of false environmental prophets who might have the right attitude, but don’t confirm to international ISO-standards. Read her blog about the subject on our articles page via this link.

Starting your own environmental certification is, as Laurel Brunner describes in her Verdigris blog, a simple way to avoid adhering to ISO XXX standards. She uses the “Cradle to Cradle” example to debunk a number of false environmental prophets who might have the right attitude, but don’t confirm to international ISO-standards. Read her blog about the subject on our articles page via this link.

Het opzetten van een eigen milieucertificaat is, zoals Laurel Brunner in haar Verdigris blog schrijft, een simpele manier om aan de echte ISO-norm te ontkomen. Met als voorbeeld: het “Cradle to Cradle” certificaat, ontmaskert Laurel een aantal valse milieuprofeten die het misschien wel goed bedoelen, maar zich niet conformeren aan de internationale ISO- standaard. Lees haar blog over dit onderwerp op onze artikelenpagina via deze link.

Het opzetten van een eigen milieucertificaat is, zoals Laurel Brunner in haar Verdigris blog schrijft, een simpele manier om aan de echte ISO-norm te ontkomen. Met als voorbeeld: het “Cradle to Cradle” certificaat, ontmaskert Laurel een aantal valse milieuprofeten die het misschien wel goed bedoelen, maar zich niet conformeren aan de internationale ISO- standaard. Lees haar blog over dit onderwerp op onze artikelenpagina via deze link.Lees verder....

Papierproductie levert volgens onderzoekers een bijproduct op dat het giftige petroleumproduct phenol zou kunnen vervangen: lignine. Phenol is de stof die houtvezels bij elkaar bindt. Nu is lignine nog een afvalproduct dat verbrand wordt om elektriciteit op te wekken. Onderzoekers van de Mississippi State University hebben nu voor het eerst phenol voor 100% kunnen vervangen door lignine bij de productie van spaanplaten. Tot nu toe kon slechts een beperkte hoeveelheid phenol, maximaal 50%, vervangen worden. Met deze aanpassing is het maken van papier weer een stuk milieuvriendelijker geworden. Lees meer over het onderzoek in het onderstaand RISI-info artikel.

Papierproductie levert volgens onderzoekers een bijproduct op dat het giftige petroleumproduct phenol zou kunnen vervangen: lignine. Phenol is de stof die houtvezels bij elkaar bindt. Nu is lignine nog een afvalproduct dat verbrand wordt om elektriciteit op te wekken. Onderzoekers van de Mississippi State University hebben nu voor het eerst phenol voor 100% kunnen vervangen door lignine bij de productie van spaanplaten. Tot nu toe kon slechts een beperkte hoeveelheid phenol, maximaal 50%, vervangen worden. Met deze aanpassing is het maken van papier weer een stuk milieuvriendelijker geworden. Lees meer over het onderzoek in het onderstaand RISI-info artikel.Lees verder....Lignin can make building materials less toxic, replaces petroleum – MSU study

August 01, 2017 – 18:01Posted in:

EAST LANSING, MI, Aug. 1, 2017 (Press Release) -A collaborative study by Mojgan Nejad, MSU forestry, proves that lignin, a byproduct of paper and bioethanol production, can completely replace phenol in phenolic adhesive formulation. This research directly impacts housing manufacturing by introducing biobased adhesives made of lignin, a renewable resource, instead of petroleum-based phenol.Nejad’s research is the first instance showing the 100 percent successful substitution of phenol with lignin. For the last 30 years, researchers have been attempting to fully replace phenol in phenol-based glues. However, only partial replacement, up to 50 percent, was possible. The research team was successful in testing plywood samples made of developed resin. When compared to commercial petroleum-based adhesives, the plywood made of lignin-based adhesives exhibited similar shear strength under both wet and dry conditions.“Our work has opened up an opportunity for the waste generated through bioethanol processes to create adhesives for engineered wood products,” Nejad said: “This will help the housing market to be less dependent on petroleum-based raw materials.”Phenol-formaldehyde resins are commonly used to manufacture construction materials such as: plywood, oriented strand board, or OSB, and laminated veneered lumber. These items make up components of roofs, kitchen cabinets, furniture, wood floors and more. Downsides of phenol-based adhesives include that they are petroleum-based. This means that production costs can fluctuate with changes in the price of oil. Additionally, chronic exposure to phenol can have health risks for workers in manufacturing plants.Lignin is an ideal substitute, because it’s considered a waste product. Isolated lignin is mostly discarded or burned to generate fuel for manufacturing. Lignin is the most abundant aromatic polymer, which makes up about 30 percent of the dry mass of plants. Nejad and collaborators have proved that it can be repurposed into green building products to replace phenol in commonly used glues.Replacing 100 percent of phenol with lignin significantly improves the percentage of renewable raw materials. It creates a new generation of bio-based adhesives, improves working conditions for manufacturers and provides employment opportunities for biorefineries.“Many major pulp and paper and bioethanol producers are keen to find applications for their lignin,” Nejad said: “We are moving to a paperless society. We can keep the jobs within the pulp and paper industry if we can introduce new products for biomass. This is one of the ways to keep the industry in business and maintain jobs in these plants.”Researchers from Mississippi State University and University of Toronto also contributed to this study. The project was funded by Poet LLC.

According to scientists the production of paper produces a by-product, lignin, that could potentially completely replace phenol, a petroleum product. Phenol is what is used to bind wood fibres. Lignin is currently a byproduct which is being burned to generate fuel. Researchers at the Mississippi State University have been able to 100% replace phenol by lignin in the production of plywood. Up to know it was only able to do so for up to 50%. With this solution the production of paper is a lot more sustainable. Read more about this research in the RISI-info article below.

According to scientists the production of paper produces a by-product, lignin, that could potentially completely replace phenol, a petroleum product. Phenol is what is used to bind wood fibres. Lignin is currently a byproduct which is being burned to generate fuel. Researchers at the Mississippi State University have been able to 100% replace phenol by lignin in the production of plywood. Up to know it was only able to do so for up to 50%. With this solution the production of paper is a lot more sustainable. Read more about this research in the RISI-info article below.

PRESS RELEASE

Lees verder....Lignin can make building materials less toxic, replaces petroleum – MSU study

A collaborative study by Mojgan Nejad, MSU forestry, proves that lignin, a byproduct of paper and bioethanol production, can completely replace phenol in phenolic adhesive formulation. This research directly impacts housing manufacturing by introducing biobased adhesives made of lignin, a renewable resource, instead of petroleum-based phenol.Nejad’s research is the first instance showing the 100 percent successful substitution of phenol with lignin. For the last 30 years, researchers have been attempting to fully replace phenol in phenol-based glues. However, only partial replacement, up to 50 percent, was possible. The research team was successful in testing plywood samples made of developed resin. When compared to commercial petroleum-based adhesives, the plywood made of lignin-based adhesives exhibited similar shear strength under both wet and dry conditions.“Our work has opened up an opportunity for the waste generated through bioethanol processes to create adhesives for engineered wood products,” Nejad said: “This will help the housing market to be less dependent on petroleum-based raw materials.”Phenol-formaldehyde resins are commonly used to manufacture construction materials such as: plywood, oriented strand board, or OSB, and laminated veneered lumber. These items make up components of roofs, kitchen cabinets, furniture, wood floors and more. Downsides of phenol-based adhesives include that they are petroleum-based. This means that production costs can fluctuate with changes in the price of oil. Additionally, chronic exposure to phenol can have health risks for workers in manufacturing plants.Lignin is an ideal substitute because it’s considered a waste product. Isolated lignin is mostly discarded or burned to generate fuel for manufacturing. Lignin is the most abundant aromatic polymer, which makes up about 30 percent of the dry mass of plants. Nejad and collaborators have proved that it can be repurposed into green building products to replace phenol in commonly used glues.Replacing 100 percent of phenol with lignin significantly improves the percentage of renewable raw materials. It creates a new generation of bio-based adhesives, improves working conditions for manufacturers and provides employment opportunities for biorefineries.“Many major pulp and paper and bioethanol producers are keen to find applications for their lignin,” Nejad said: “We are moving to a paperless society. We can keep the jobs within the pulp and paper industry if we can introduce new products for biomass. This is one of the ways to keep the industry in business and maintain jobs in these plants.”Researchers from Mississippi State University and University of Toronto also contributed to this study. The project was funded by Poet LLC.

De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK