Rob van den Braak

If you want to see how luxury packaging can sell a product, have a look at MW Luxury Packaging site to see the box the company made for La Mer. MW used all possible print and finishing technology to seduce the buyer and add value to La Mer´s new Hydrating Serum. The idea behind the box is the pop-up book. A book which comes to life through special foils which remind you of the colours of the sea. After opening the box the pop-up gives information about the product. The need for the product is emphasised by a simple tool, a movable mirror. If you were tempted to spend a lot of money, don´t bother as the box is not for sale. It has been produced in a limited edition and sent to a select number of influencers. But it is a good example of what the packaging industry can produce if money is no object.

Lees verder....

Apple is aspiring to become the first big computer manufacturer to only used recycled source materials in future. To fulfill Steve Jobs´ wishes the company has drawn up a schedule. The first step will be to only use aluminium from old computers. According to insiders Apple devices which are handed in will become the source of minerals and metals. Part of the plan are recycling schemes which are currently not yet very popular because the value on the open market is bigger or the emotional attachment to a device is stronger. But the stream of recycled devices is slowly becoming bigger and, who knows, there may come a Device as a Service offer which will have so many advantages to both the user and Apple that mining for metals and minerals will no longer be necessary.

Apple is aspiring to become the first big computer manufacturer to only used recycled source materials in future. To fulfill Steve Jobs´ wishes the company has drawn up a schedule. The first step will be to only use aluminium from old computers. According to insiders Apple devices which are handed in will become the source of minerals and metals. Part of the plan are recycling schemes which are currently not yet very popular because the value on the open market is bigger or the emotional attachment to a device is stronger. But the stream of recycled devices is slowly becoming bigger and, who knows, there may come a Device as a Service offer which will have so many advantages to both the user and Apple that mining for metals and minerals will no longer be necessary.

Lees verder....

Apple wil als eerste grote computerfabrikant in de toekomst alleen nog gebruik maken van gerecyclede grondstoffen. Het bedrijf heeft als invulling van de belofte, die Steve Jobs ooit deed, een schema opgesteld om deze ambitie waar te maken. Als eerste zal het voor zijn behoefte aan aluminium uitsluitend gebruik maken van aluminium, gewonnen uit oude computers. Volgens insiders kunnen teruggenomen Apple devices binnenkort ook de bron worden van zeldzame mineralen en metalen. Onderdeel van dit plan zijn inruilacties die jammergenoeg nog niet zo succesvol zijn, omdat de restwaarde op de vrije markt of de emotionele binding, die gebruikers met hun oude device hebben, nog een te grote invloed heeft. Maar langzaam maar zeker groeit de stroom ingenomen devices, en wie weet komt er straks een “Device as a Service” aanbieding die én voor de gebruiker én voor Apple zoveel voordelen heeft, dat het mijnen van metalen en mineralen niet meer nodig is.

Apple wil als eerste grote computerfabrikant in de toekomst alleen nog gebruik maken van gerecyclede grondstoffen. Het bedrijf heeft als invulling van de belofte, die Steve Jobs ooit deed, een schema opgesteld om deze ambitie waar te maken. Als eerste zal het voor zijn behoefte aan aluminium uitsluitend gebruik maken van aluminium, gewonnen uit oude computers. Volgens insiders kunnen teruggenomen Apple devices binnenkort ook de bron worden van zeldzame mineralen en metalen. Onderdeel van dit plan zijn inruilacties die jammergenoeg nog niet zo succesvol zijn, omdat de restwaarde op de vrije markt of de emotionele binding, die gebruikers met hun oude device hebben, nog een te grote invloed heeft. Maar langzaam maar zeker groeit de stroom ingenomen devices, en wie weet komt er straks een “Device as a Service” aanbieding die én voor de gebruiker én voor Apple zoveel voordelen heeft, dat het mijnen van metalen en mineralen niet meer nodig is.

Laurel Brunner writes about a rather unknown problem in her Verdigris blog. Energy calculation for digital presses. She explains that it starts with the large amount of variables of a print, such as ink coverage and the number of copies. On top of that there is the energy use for the different kinds of finishings. Read her article about this problem which only increases when clients become more critical of sustainability in print, via this link to our articles page.

Laurel Brunner writes about a rather unknown problem in her Verdigris blog. Energy calculation for digital presses. She explains that it starts with the large amount of variables of a print, such as ink coverage and the number of copies. On top of that there is the energy use for the different kinds of finishings. Read her article about this problem which only increases when clients become more critical of sustainability in print, via this link to our articles page.

Lees verder....

In haar Verdigris Blog kaart Laurel Brunner een niet zo bekend probleem aan. Het berekenen van het energieverbruik van een digitale pers. Zoals ze uitlegt begint het met de grote hoeveelheid variabelen die in elke afdruk zitten, zoals: de inktdekking en het aantal afdrukken. Daarbovenop komt nog het energieverbruik van alle mogelijke soorten afwerking van die afdrukken. Lees haar artikel over dit probleem, dat groter wordt naarmate klanten kritischer worden over hoe duurzaam drukwerk geproduceerd wordt. via deze link naar onze artikelenpagina.

In haar Verdigris Blog kaart Laurel Brunner een niet zo bekend probleem aan. Het berekenen van het energieverbruik van een digitale pers. Zoals ze uitlegt begint het met de grote hoeveelheid variabelen die in elke afdruk zitten, zoals: de inktdekking en het aantal afdrukken. Daarbovenop komt nog het energieverbruik van alle mogelijke soorten afwerking van die afdrukken. Lees haar artikel over dit probleem, dat groter wordt naarmate klanten kritischer worden over hoe duurzaam drukwerk geproduceerd wordt. via deze link naar onze artikelenpagina.

Lees verder....

De in Porth, UK, gevestigde Beatus Cartons wordt de eerste verpakkingsdrukker met een KBA Rapida 106, uitgerust met een QualiTronic PDF-systeem. Het systeem zorgt niet alleen voor een optimale afdrukkwaliteit, maar controleert op basis van een door de klant aangeleverde 300 dpi PDF, ook of de afdruk exact is zoals bedoeld. De Rapida 106 is een zeven kleuren offsetpers met twee coating units, voor zowel de standaard als UV-lakken, en wordt in de herfst geïnstalleerd. Het bijna 80-jarige familiebedrijf investeerde niet alleen in deze super gespecificeerde offsetpers, maar ook in een compleet nieuwe verpakkingsontwerpstudie met een digitaal proofing systeem.

De in Porth, UK, gevestigde Beatus Cartons wordt de eerste verpakkingsdrukker met een KBA Rapida 106, uitgerust met een QualiTronic PDF-systeem. Het systeem zorgt niet alleen voor een optimale afdrukkwaliteit, maar controleert op basis van een door de klant aangeleverde 300 dpi PDF, ook of de afdruk exact is zoals bedoeld. De Rapida 106 is een zeven kleuren offsetpers met twee coating units, voor zowel de standaard als UV-lakken, en wordt in de herfst geïnstalleerd. Het bijna 80-jarige familiebedrijf investeerde niet alleen in deze super gespecificeerde offsetpers, maar ook in een compleet nieuwe verpakkingsontwerpstudie met een digitaal proofing systeem.

Lees meer over deze investering in onderstaand persbericht.

PRESS RELEASE

Beatus Cartons invests in a highly specified Rapida 106 and focuses on a bright future

Porth based, high quality carton printer Beatus Cartons has purchased a highly specified Rapida 106 7 colour with double coating facility. The new press, which will be installed in Autumn 2017 will replace an existing Heidelberg CD 102 5 plus coater. The new press is the latest stage in an exciting investment programme that has seen a brand new, state of the art innovation centre constructed to house a new carton design studio and their recently purchased digital proofing equipment.

Beatus Cartons (originally known as Jacob Beatus after its founder) is a proud, family owned business which was established in 1940. Based in Porth in the Rhondda Valley they specialise in providing folding printed cartons in solid board, litho laminated flute and plastic packaging for the food, pharmaceutical, confectionery, motor, glassware, health and beauty industries. Many of the 55 employees at the 77 year ‘young’, £5 million turnover business have been with the company for many years (some in excess of 40 years!). It is this level of dedication and commitment which has helped the business to thrive and maintain a very loyal customer base as well as regularly attracting new clients.

Managing Director Clive Stinchcombe states: ‘We may be 77 years old, but we prefer to think of the business as 77 years young. We are a forward thinking company, proud of our longevity, but equally excited by the future that lies ahead.’ He continues: ‘With our investment in the Rapida 106, we will now be able to offer seven colour printing for the first time, greater running speeds, significant reductions in make ready times and waste and in addition, we are able to offer a great range of special coating finishes for our clients. We believe the new press with all its automation and the move to one pass productivity, has the potential to increase our turnover by at least 50%.’

The press was extensively specified to meet the exact requirements of the Beatus Cartons technical team, following testing at KBA’s sheet-fed solutions facility in Dresden. KBA also arranged reference visits and discussions with several new users, who have switched to Rapida 106 technology from other manufacturers.

Mr Stinchcombe saw this as a real positive in the evaluation process, a distinct factor was the success. KBA have enjoyed in recent years with folding carton printers. They appear to be the “go to company” for carton manufacturers like us. They are completely focussed on carton print technology and their overall levels of service and support are with this in mind. This is what we need from our print machinery supplier; a good product, and a company with a good back up service, which puts training and development on an equal footing.

Fastest Changeovers

The new press will provide the highest levels of productivity, with a top speed of 18,000 SPH and fully automatic plate changing technology (FAPC), which allows all the plates to be changed in less than 3 minutes. The press is also equipped with KBA’s unique sensoric infeed system (SIS) and roller declutching which are standard items on the 106 Rapida range. In addition, the press is being shipped with simultaneous roller washing, which allows a set of rollers to be washed whilst the press is running ensuring rapid change overs for special colours.

Ultimate Flexibility

More efficient production on a broad range of substrates is possible, with the new press as it is equipped with both a CX package and a plastics package; this will allow printing of a great variety of materials of up to 1.2mm thick. The press is being supplied with capability for production with both conventional and UV inks and coatings, and is equipped with a water cooling facility which greatly reduces heat in the press hall, and reduces wear and tear on the peripheral components. The UV lamps (including a special white cure lamp) are equipped with UV sensors which monitor the levels of UV energy directly from the lamp.

Unrivalled Quality Control

Beatus Cartons will be the first company in the UK to have a Rapida 106 supplied with KBA’s QualiTronic PDF system. This feature allows automatic, inline comparison with customer supplied PDF’s. With a resolution of 300 DPI and fully automatic fault logging, this system provides the ultimate in sheet inspection.

The company supplies products for the pharmaceutical industry which places extremely high demands for quality compliance on printers. The QualiTronic PDF system has ensured they can now provide an unrivalled, high resolution inspection solution with extensive reporting for their clients, which will also reduce waste in both time and materials.

Mr Stinchcombe states: ‘The inline quality control of this machine is one of its biggest attractions and will allow us to achieve a more consistent and reliable level of quality, without having to compromise on running speeds.

For inline colour control at the highest speeds with the lowest waste count on every make ready, the press is equipped with QualiTronic ColorControl; KBA’s inline colour measurement system, alongside the Ergotronic Colour control desk for standardised print, quality analysis and reporting.

The performance data of the press will be automatically captured for analysis via KBA’s LogoTronic Professional, which will provide detailed reports on every activity taking place on the press. The LogoTronic system has also been extended to include Logotronic Cockpit which provides detailed reports on the presses OEE performance. The LogoTronic system also provides the link to pre-press, an MIS system and allows the storage of the colour quality data produced by the press via KBA’s QualiTronic QualityPass and QualiTronic ColorView.

Personal Approach

Reflecting on the decision to purchase a press from KBA, Mr Stinchcombe adds: ‘During the investment process we looked at both Heidelberg and Komori. However, we were bowled over by the inline quality system and KBA gave us a huge degree of confidence. It was a very personal approach, but conducted in highly professional manner from the outset. We were particularly impressed by the level of personal service afforded to us by KBA UK Area Sales Manager Peter Banks, who not only held our hand throughout the whole process. He also possesses an additional likeability factor, which mirrors the philosophy of personal service we have with our own customers. We hope that this is the start of a long and happy relationship.’

KBA (UK) Ltd. Sales Director Chris Scully added: ‘We are delighted to welcome Beatus Cartons to our ever growing band of printers, who are selecting the Rapida 106 as their press of choice for carton manufacturing. They are a proud company with a long history and the exciting features for both quality control and efficient make ready on this press will help to truly set them apart from their competition and to ensure that their business continues to thrive and grow.

Lees verder.... Beatus Cartons, located in Port, UK, will be the first packaging printer with a KBA Rapida 106 equipped with a QualiTronic PDF system. The system does not only ensure optimal print quality, but also checks the print based on the 300 dpi PDF received from the client. The Rapida 106 is a seven colour offset press with two coating units, standard and UV. All is set to be installed in the autumn. The 80-year old family company not only invested in this super specified offset press but also in a completely new design studio with a digital proofing system.

Beatus Cartons, located in Port, UK, will be the first packaging printer with a KBA Rapida 106 equipped with a QualiTronic PDF system. The system does not only ensure optimal print quality, but also checks the print based on the 300 dpi PDF received from the client. The Rapida 106 is a seven colour offset press with two coating units, standard and UV. All is set to be installed in the autumn. The 80-year old family company not only invested in this super specified offset press but also in a completely new design studio with a digital proofing system.

Read more about this investment in the press release below.

PRESS RELEASE

Beatus Cartons invests in a highly specified Rapida 106 and focuses on a bright future

Porth based, high quality carton printer Beatus Cartons has purchased a highly specified Rapida 106 7 colour with double coating facility. The new press, which will be installed in Autumn 2017 will replace an existing Heidelberg CD 102 5 plus coater. The new press is the latest stage in an exciting investment programme that has seen a brand new, state of the art innovation centre constructed to house a new carton design studio and their recently purchased digital proofing equipment.

Beatus Cartons (originally known as Jacob Beatus after its founder) is a proud, family owned business which was established in 1940. Based in Porth in the Rhondda Valley they specialise in providing folding printed cartons in solid board, litho laminated flute and plastic packaging for the food, pharmaceutical, confectionery, motor, glassware, health and beauty industries. Many of the 55 employees at the 77 year ‘young’, £5million turnover business have been with the company for many years (some in excess of 40 years!). It is this level of dedication and commitment which has helped the business to thrive and maintain a very loyal customer base as well as regularly attracting new clients.

Managing Director Clive Stinchcombe states: ‘We may be 77 years old but we prefer to think of the business as 77 years young. We are a forward thinking company, proud of our longevity, but equally excited by the future that lies ahead.’ He continues ‘With our investment in the Rapida 106 we will now be able to offer seven colour printing for the first time, greater running speeds, significant reductions in make ready times and waste and in addition, we are able to offer a great range of special coating finishes for our clients. We believe the new press with all its automation and the move to one pass productivity has the potential to increase our turnover by at least 50%.’

The press was extensively specified to the meet the exact requirements of the Beatus Cartons technical team following testing at KBA’s sheet-fed solutions facility in Dresden. KBA also arranged reference visits and discussions with several new users who have switched to Rapida 106 technology from other manufacturers.

Mr Stinchcombe saw this as a real positive in the evaluation process ‘A distinct factor was the success KBA have enjoyed in recent years with folding carton printers. They appear to be the “go to company” for carton manufacturers like us. They are completely focussed on carton print technology and their overall levels of service and support are with this in mind. This is what we need from our print machinery supplier; a good product, and a company with a good back up service which puts training and development on an equal footing.”

Fastest Changeovers

The new press will provide the highest levels of productivity with a top speed of 18,000 SPH and fully automatic plate changing technology (FAPC) which allows all the plates to be changed in less than 3 minutes. The press is also equipped with KBA’s unique sensoric infeed system (SIS) and roller declutching which are standard items on the 106 Rapida range. In addition, the press is being shipped with simultaneous roller washing which allows a set of rollers to be washed whilst the press is running ensuring rapid change overs for special colours.

Ultimate Flexibility

More efficient production on a broad range of substrates is possible with the new press as it is equipped with both a CX package and a plastics package; this will allow printing of a great variety of materials of up to 1.2mm thick. The press is being supplied with capability for production with both conventional and U.V. inks and coatings, and is equipped with a water cooling facility which greatly reduces heat in the press hall and reduces wear and tear on the peripheral components. The UV lamps (including a special white cure lamp) are equipped with UV sensors which monitor the levels of UV energy directly from the lamp.

Unrivalled Quality Control

Beatus Cartons will be the first company in the UK to have a Rapida 106 supplied with KBA’s QualiTronic PDF system. This feature allows automatic, inline comparison with customer supplied PDF’s. With a resolution of 300 DPI and fully automatic fault logging, this system provides the ultimate in sheet inspection.

The company supplies products for the pharmaceutical industry which places extremely high demands for quality compliance on printers. The QualiTronic PDF system has ensured they can now provide an unrivalled, high resolution inspection solution with extensive reporting for their clients which will also reduce waste in both time and materials.

Mr Stinchcombe states: ‘The inline quality control of this machine is one of its biggest attractions and will allow us to achieve a more consistent and reliable level of quality without having to compromise on running speeds.

For inline colour control at the highest speeds with the lowest waste count on every make ready, the press is equipped with QualiTronic ColorControl; KBA’s inline colour measurement system, alongside the Ergotronic Colour control desk for standardised print, quality analysis and reporting.

The performance data of the press will be automatically captured for analysis via KBA’s LogoTronic Professional which will provide detailed reports on every activity taking place on the press. The Logotronic system has also been extended to include Logotronic Cockpit which provides detailed reports on the presses OEE performance. The LogoTronic system also provides the link to pre-press, an MIS system and allows the storage of the colour quality data produced by the press via KBA’s Qualitronic QualityPass and QualiTronic ColorView.

Personal Approach

Reflecting on the decision to purchase a press from KBA Mr Stinchcombe adds ‘During the investment process we looked at both Heidelberg and Komori. However, we were bowled over by the inline quality system and KBA gave us a huge degree of confidence. It was a very personal approach but conducted in highly professional manner from the outset. We were particularly impressed by the level of personal service afforded to us by KBA UK Area Sales Manager Peter Banks, who not only held our hand throughout the whole process. He also possesses an additional likeability factor which mirrors the philosophy of personal service we have with our own customers. We hope that this is the start of a long and happy relationship.’

KBA (UK) Ltd. Sales Director Chris Scully added: ‘We are delighted to welcome Beatus Cartons to our ever growing band of printers who are selecting the Rapida 106 as their press of choice for carton manufacturing. They are a proud company with a long history and the exciting features for both quality control and efficient make ready on this press will help to truly set them apart from their competition and to ensure that their business continues to thrive and grow.

Lees verder....More about this very promising technology on iMore via this link.

Lees verder....

Apple ProMotion & Affinity Photo

Net als de Apple retina beeldschermen de norm hebben gezet voor beeldweergave, gaat ProMotion beeldbewegingen naar een ongekend niveau brengen. Met een refresh rate van 120Hz zullen bewegingen zo vloeiend worden dat elk ‘schok’effect verdwijnt. Niet alleen voor beeldweergave is ProMotion belangrijk, maar ook voor beeldmanipulatie in combinatie met de Apple Pencil. Daarmee kun je straks snel en simpel beelden vrijstaand maken, maskers creëren en kleuren aanpassen. ProMotion wordt mogelijk gemaakt door de nieuwe iPad Pro A10x processor die de refresh rate dynamisch aanpast aan handelingen die je verricht. Dankzij deze functie wordt de levensduur van de batterij verlengd. ProMotion zal ons veel tijd besparen bij beeldmanipulaties en het kijkgenot aanmerkelijk verhogen. ProMotion is nu beschikbaar voor de nieuwe iPad Pro’s, maar zal ongetwijfeld, net als de Retina beeldschermen, straks op andere Apple devices toegepast gaan worden.

Lees meer over deze veelbelovende techniek op iMore via deze link.

Lees verder....

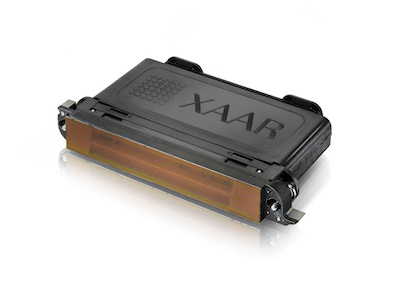

Fabrikanten van production inkjet systemen krijgen met de nieuwe Xaar 5501 printhead de kans om water-based inkten te gebruiken in hun printers.

De nieuwe lichtgewicht en compacte Xaar 5501 printhead met 5544 nozzles en een output resolutie van 1.200 dpi, is geschikt voor een breed scala aan beschikbare milieuvriendelijke water-based inkten, maar ook voor lage viscositeit UV of solvent inkten. Naar verwachting zullen voor het einde van het jaar een aantal OEM-fabrikanten productie inkjet systemen met deze nieuwe printhead aankondigen. Lees meer over de Xaar 5501 in het onderstaande persbericht.

PERSBERICHT

Xaar strengthens aqueous printhead portfolio with the Xaar 5501.

Xaar, world leader in industrial inkjet technology, is delighted to announce the Xaar 5501, a new addition to its portfolio of aqueous printheads. Previewing on Xaar’s stand at Ceramics China and available later this year, the compact and lightweight Xaar 5501 complements the existing Xaar 1201 and Xaar 5601, and provides OEMs looking for an aqueous printhead from Xaar with a wider choice. This is the first product resulting from Xaar’s collaboration with Xerox and delivers high print quality combined with low printing costs whilst integration costs will also be kept to a minimum.

The new Xaar 5501, which uses proven bulk piezo technology in conjunction with Xaar Drive Electronics, delivers high print quality. Original Equipment Manufacturers (OEMs) can use this printhead to deliver cost-effective scanning digital printers with a high quality output.

This is a lightweight and high resolution 1200 dpi printhead, which is ideal for a range of water-based digital printing applications, such as textiles (digital direct to garment, dye sublimation transfer and soft signage) and graphics (banners, posters, displays). It has 5544 nozzles, each producing 5 pL sub-drops giving an impressive 115 mm print width for high quality print at high productivity. Furthermore, the Xaar 5501’s robust construction makes it compatible with a range of fluids including aqueous inks, low viscosity UV or solvent-based inks.

The Xaar 5501 uses a simple micro alignment system to position and align printheads via software. This allows rapid and easy printer set up, therefore streamlining printhead commissioning and reducing downtime overall. In addition, it does not require an ink recirculation system; this ensures lower integration costs and makes it very suitable to use in scanning applications such as printing wide-format graphics and textiles. In addition, for high productivity applications, single-pass printing is possible.

“We are delighted to be bringing the Xaar 5501 to market,” comments Jason Remnant, Senior Product Manager at Xaar. “With this addition to our aqueous portfolio we now have a full range of solutions to meet the majority of applications, which need low viscosity-compatible inkjet printheads. With its simple ink supply system, the Xaar 5501 is a very cost effective solution for scanning textile and wide-format graphics printers, and will be widely available to OEMs later this year.

Lees verder....Manufacturers of production inkjet systems will be able to use the new Xaar 5501 printhead to enable water-based inks for their systems.

The new lightweight and compact Xaar 5501 printhead with 5544 nozzles and an output resolution of 1,200 dpi is suitable for a wide variety of environmentally friendly water-based inks, but also for low viscosity UV or solvent inks. It is to be expected that the manufacturers will announce production inkjet systems with this new printhead. Read more about the Xaar 5501 in the press release below.

PRESS RELEASE

Xaar strengthens aqueous printhead portfolio with the Xaar 5501

Xaar, world leader in industrial inkjet technology, is delighted to announce the Xaar 5501, a new addition to its portfolio of aqueous printheads. Previewing on Xaar’s stand at Ceramics China and available later this year, the compact and lightweight Xaar 5501 complements the existing Xaar 1201 and Xaar 5601, and provides OEMs looking for an aqueous printhead from Xaar with a wider choice. This is the first product resulting from Xaar’s collaboration with Xerox and delivers high print quality combined with low printing costs whilst integration costs will also be kept to a minimum.

The new Xaar 5501, which uses proven bulk piezo technology in conjunction with Xaar Drive Electronics, delivers high print quality. Original Equipment Manufacturers (OEMs) can use this printhead to deliver cost-effective scanning digital printers with a high quality output.

This is a lightweight and high resolution 1200 dpi printhead which is ideal for a range of water-based digital printing applications, such as textiles (digital direct to garment, dye sublimation transfer and soft signage) and graphics (banners, posters, displays). It has 5544 nozzles, each producing 5 pL sub-drops giving an impressive 115 mm print width for high quality print at high productivity. Furthermore, the Xaar 5501’s robust construction makes it compatible with a range of fluids including aqueous inks, low viscosity UV or solvent-based inks.

The Xaar 5501 uses a simple micro alignment system to position and align printheads via software. This allows rapid and easy printer set up, therefore streamlining printhead commissioning and reducing downtime overall. In addition, it does not require an ink recirculation system; this ensures lower integration costs and makes it very suitable to use in scanning applications such as printing wide-format graphics and textiles. In addition, for high productivity applications, single-pass printing is possible.

“We are delighted to be bringing the Xaar 5501 to market,” comments Jason Remnant, Senior Product Manager at Xaar. “With this addition to our aqueous portfolio we now have a full range of solutions to meet the majority of applications which need low viscosity-compatible inkjet printheads. With its simple ink supply system, the Xaar 5501 is a very cost effective solution for scanning textile and wide-format graphics printers, and will be widely available to OEMs later this year. We will make further announcements i

Lees verder.... The European Parliament (EP) has agreed last week to allow a reduction in VAT for ebooks to match printed books. This means a reduction from 21% to 6% for digital books, newspapers and magazines. Up to now the lower VAT rate was only applicable to printed media. A majority thought that this inequality ad to end. The European Commission proposed the change and the European Parliament agreed to this. EU member states are now able to reduce the VAT reduction for online media.

The European Parliament (EP) has agreed last week to allow a reduction in VAT for ebooks to match printed books. This means a reduction from 21% to 6% for digital books, newspapers and magazines. Up to now the lower VAT rate was only applicable to printed media. A majority thought that this inequality ad to end. The European Commission proposed the change and the European Parliament agreed to this. EU member states are now able to reduce the VAT reduction for online media.

Lees verder....

De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK