Rob van den Braak

We were, as Laurel Brunner describes in her Verdigris blog, doing really well with the recycling of paper and paper manufacturers were always finding new ways to use recycled paper pulp. In her Waste and Guilt blog, on our articles page, Laurel describes how the burning of paper, especially in new economies, is putting a halt to this and how good information can help.

We were, as Laurel Brunner describes in her Verdigris blog, doing really well with the recycling of paper and paper manufacturers were always finding new ways to use recycled paper pulp. In her Waste and Guilt blog, on our articles page, Laurel describes how the burning of paper, especially in new economies, is putting a halt to this and how good information can help.

Lees verder....

We waren, zoals Laurel Brunner schrijft in haar Verdigris Blog, goed op weg met de recycling van papier, en papierfabrikanten vonden steeds betere methodes om pulp van oud papier te gebruiken voor nieuw papier. Lees in haar bijdrage op onze artikelenpagina hoe het verbranden van papier samen met gewoon afval, deze trend, vooral in de nieuwe economieën, om kan buigen en hoe goede voorlichting dit tij kan keren.

We waren, zoals Laurel Brunner schrijft in haar Verdigris Blog, goed op weg met de recycling van papier, en papierfabrikanten vonden steeds betere methodes om pulp van oud papier te gebruiken voor nieuw papier. Lees in haar bijdrage op onze artikelenpagina hoe het verbranden van papier samen met gewoon afval, deze trend, vooral in de nieuwe economieën, om kan buigen en hoe goede voorlichting dit tij kan keren.

Lees verder....

There was something special about the cover of the programme of the 70th edition of the prestigious film festival in Cannes. All 34,000 offset printed brochures are unique. Graphics designer Phillipe Savoir, together with printer Art&Caractere in Toulouse, made small changes by hand to each of the programmes which makes them unique. They worked with different directions and different print plates and the colours were mixed to achieve tones of red, orange, pink and violet.

There was something special about the cover of the programme of the 70th edition of the prestigious film festival in Cannes. All 34,000 offset printed brochures are unique. Graphics designer Phillipe Savoir, together with printer Art&Caractere in Toulouse, made small changes by hand to each of the programmes which makes them unique. They worked with different directions and different print plates and the colours were mixed to achieve tones of red, orange, pink and violet.

Lees verder....

An unstoppable trend is the use of robots for work that is now being done by humans. According to research, such as by Forrester, this will impact nearly 30 million jobs over the coming 10 years. The good news is that robotics will also create millions of jobs. Forrester predicts about 15 million jobs. These numbers concern the US. What the impact of robotics will be in Europe we don´t know. What we do know is that our industry does not have many jobs which can be done cheaper or better by robots. The automation of print and finishing processes has already taken jobs, a loss which unfortunately is not compensated by a bigger demand for print.

An unstoppable trend is the use of robots for work that is now being done by humans. According to research, such as by Forrester, this will impact nearly 30 million jobs over the coming 10 years. The good news is that robotics will also create millions of jobs. Forrester predicts about 15 million jobs. These numbers concern the US. What the impact of robotics will be in Europe we don´t know. What we do know is that our industry does not have many jobs which can be done cheaper or better by robots. The automation of print and finishing processes has already taken jobs, a loss which unfortunately is not compensated by a bigger demand for print.

Read the article on techrepublic.com via this link about the development of robotics in the US.

Lees verder....

Een niet te stoppen trend is het gebruik van robots, voor werkzaamheden die nu door mensen gedaan worden. Volgens rapporten, zoals van Forrester, betreft dit de komende 10 jaar bijna 30 miljoen banen. Het goede nieuws is, dat deze robotisering ook miljoenen banen oplevert. Forrester denkt dat dit er tenminste 15 miljoen zullen zijn. Dit zijn cijfers voor Amerika. Wat de impact van robotisering zal zijn in Europa, is zover wij weten niet bekend. Wat we wel weten is, dat in onze industrie er niet zo heel veel werkzaamheden zijn die goedkoper of beter door robots gedaan kunnen worden. Maar de automatisering van het druk- en afwerkingsproces heeft al banenverlies opgeleverd, een verlies dat helaas niet gecompenseerd wordt door een grotere vraag naar drukwerk.

Een niet te stoppen trend is het gebruik van robots, voor werkzaamheden die nu door mensen gedaan worden. Volgens rapporten, zoals van Forrester, betreft dit de komende 10 jaar bijna 30 miljoen banen. Het goede nieuws is, dat deze robotisering ook miljoenen banen oplevert. Forrester denkt dat dit er tenminste 15 miljoen zullen zijn. Dit zijn cijfers voor Amerika. Wat de impact van robotisering zal zijn in Europa, is zover wij weten niet bekend. Wat we wel weten is, dat in onze industrie er niet zo heel veel werkzaamheden zijn die goedkoper of beter door robots gedaan kunnen worden. Maar de automatisering van het druk- en afwerkingsproces heeft al banenverlies opgeleverd, een verlies dat helaas niet gecompenseerd wordt door een grotere vraag naar drukwerk.

Lees op techrepublic.com via deze link meer over de ontwikkeling van robotisering in Amerika.

Lees verder....Dit jaar viert KBA dat Friedrich Koenig en Andreas Bauer in 1817 hun eerste drukpersenfabriek in gebruik namen. De geschiedenis van KBA is ook de geschiedenis van onze industrie. De eerste hoogdruk cilinderpersen die de fabriek in Oberzeil verlieten, waren het begin van de industrialisatie van de grafische industrie die uitmondde in de super geautomatiseerde grootformaat offsetpersen en digitale productie printers die nu, dankzij de revival van drukwerk wereldwijd, in grote aantallen geïnstalleerd worden.

KBA speelt, net als 200 jaar geleden, daar een grote rol in. Het bedacht een aantal unieke concepten, zoals de supersnelle Condor snelpers en de Cortina waterloze offset kranten rotatiepers. Ook de grootformaat oplossingen8, zoals KBA die de Rapid-serie aanbiedt en de samen met HP ontwikkelde T1100 S, de breedste digitale verpakkingspers, schrijven geschiedenis.

De KBA geschiedenis is ook mijn persoonlijke geschiedenis in deze industrie. De Gala, gemaakt door het later door KBA overgenomen Albert Frankenthal, was de eerste middenformaat hoogdrukpers die ik als leerling boekdrukker mocht bedienen. En de Condor was de snelste middenformaat pers, waarmee ik in het vorige millenium heb mogen werken. Als journalist voor PERS mocht ik in 2013 bij de introductie van de Rapida 164 super grootformaat offset pers zijn. Het was een onvergetelijke ervaring om te zien hoe dat drukmonster binnen een paar minuten zijn platen wisselde en zijn topsnelheid van 18.000 druks per uur haalde.

Felicitaties voor KBA zijn dan ook op zijn plaats, en we zijn benieuwd hoe over 200 jaar onze industrie er, dankzij pioniers als KBA, uit zal zien.

Lees hieronder de complete geschiedenis van KBA.

200 years Koenig & Bauer Innovation-lined road from the first cylinder press to digital print

In August 2017, Koenig & Bauer AG (KBA) in Würzburg will be celebrating its 200th anniversary. The world’s first press-building workshop of 1817 has since blossomed into a globally successful manufacturing group with a unique portfolio of solutions for the printing industry. Anniversary festivities are planned from 21st to 23rd September – an ideal occasion to review past achievements and to present the visions which will determine the company’s strategy and market position in the third century of its history.

Breakthrough in London

Breakthrough in London

The times have certainly changed. In the early 19th century, Germany still lacked venturesome investors and a fertile industrial environment. It was not least for this reason that trained printer and untiring inventor Friedrich Koenig travelled to London in 1807 to realise his idea of a steam-driven printing press. While there, he met precision engineer Andreas Bauer, and in November 1814, The Times became the first newspaper to be printed on their double-cylinder press. This laid the foundations for printing on an industrial scale and for access to print media for a much broader section of the population.

Production in a former monastery

On 9th August 1817, Friedrich Koenig and Andreas Bauer signed a contract establishing Schnellpressenfabrik Koenig & Bauer in a secularised monastery in Oberzell near Würzburg, and in 1823, the Haude und Spenersche Zeitung in Berlin was the first newspaper on the European continent to be printed on presses from Oberzell.

Friedrich Koenig died in 1833. His widow Fanny Koenig and his former business partner Andreas Bauer continued his work. New presses were developed and the one-hundredth press was already delivered in 1838. A number of ambitious young workers moved away to found their own businesses. In this sense, Oberzell can be considered the cradle of German printing press manufacture. The company’s foundation period came to an end with the death of Andreas Bauer in 1860.

Early social achievements

The founder’s two sons, Wilhelm Koenig and Friedrich Koenig Jr., developed new presses, modernised factory routines and introduced a series of social reforms. The sickness benefit fund founded in 1855 was followed by a factory savings bank in 1865 and by a factory training school, the precursor of today’s vocational training centre in Würzburg, in 1868. The factory statute of 1873 defined the rights and duties of workers and managers and established a factory council ‒ employee participation already 140 years ago.

1876: The era of web printing begins

The first webfed press was supplied to a newspaper in Magdeburg in 1876. Wilhelm Koenig invented the variable web press in 1886, designed the first four-colour press in 1888, and began building special machines for the printing of luxury products. At the same time, he became very interested in securities printing, a field in which Koenig & Bauer was later to become technology leader. In 1895, the 5000th cylinder press left the factory.

From 1895 and through into the 1920s, the course of the company was shaped by Constantin Koenig and the founder’s grandson Albrecht Bolza. In 1901, a new factory was built at the site today occupied by the company headquarters. The 225 metre long production hall was one of the largest in Germany at that time. Webfed publication and rotogravure presses were manufactured, and the development of sheetfed machines was stepped up. Alongside printing presses, various matrix-moulding presses and plate-casting machines were delivered to customers all over the world.

Destruction and rebuilding

After the First World War, Dr. Hans Bolza, a great-grandson of Friedrich Koenig, made a notable contribution to the mending of severed foreign business links. He was appointed to the executive board of the company when it was transformed into a limited company in 1920 and served as chairman of the board from 1931 to 1971.

Koenig & Bauer survived the period of hyperinflation in the 1920s thanks to the newly developed Iris collect press for coloured banknotes. In March 1945, bombs and artillery shells destroyed the Würzburg factories. Reconstruction began in 1946. After the post-war currency reform, Koenig & Bauer resumed business in 1949 with nominal capital amounting to DM 4.1 million.

1952: Success story of security printing

Cooperation with securities printing expert Gualtiero Giori began in 1952. A further important milestone was the arrival of a talented young design engineer named Dr. Hans-Bernhard Schünemann, the son of a Bremen publishing family, in 1951. His first of over 250 patents was granted for a modification of the so called Maltese cross drive mechanism, which was subsequently used in another of his inventions, the sheetfed gravure press Rembrandt MT III. In 1959, Dr. Hans Bolza formally adopted Dr. Schünemann.

Dr. Bolza-Schünemann was himself president of Koenig & Bauer AG for almost 25 years from 1971 to 1995, and initiated the formation of the KBA Group from 1990. Executive responsibility was subsequently placed in the hands of his close partner and long-serving financial director Reinhart Siewert. After the turn of the century, he was succeeded by Albrecht (2003 – 2009) and Claus Bolza-Schünemann (since 2011), who thus represent the sixth generation of the founding family at the helm of the company.

Dr. Hans Bolza † (CEO from 1931 to 1971) and Dr. Hans-Bernhard Bolza-Schünemann † (CEO from 1971 to 1995)

Successful presses Condor and Rotafolio

Despite the growing offset competition in the 1960s and 70s, Koenig & Bauer retained the proven letterpress technology for its sheetfed and webfed presses for a relatively long time. Alongside the Rembrandt sheetfed gravure press and banknote presses developed together with De La Rue Giori, the two-revolution Condor and the Rotafolio sheetfed press for wrap-around plates were extremely successful all over the world.

High-performance in sheetfed offset since 1974

The first sheetfed offset press, the half-format Koebau-Rapida 0, was presented at drupa in 1967. The medium-format Koebau-Rapida III followed in 1969. Both ran at speeds up to 8,000 sheets per hour. The Koebau-Rapida SR III launched in 1974 was almost twice as fast at 15,000 sheets per hour. The presses of other major manufacturers did not achieve such performance until much later.

In 1986, Koenig & Bauer launched the Rapida 104, a unit-type press designed for high flexibility and printing speeds up 15,000 sheets per hour. Production was transferred to the new subsidiary KBA-Planeta AG in 1992, sowing the seed for today’s high-performance sheetfed offset presses from Radebeul. The current Rapida 106, for example, has defined the benchmarks in medium format with speeds up to 20,000 sheets per hour, extremely fast job changeovers and configurations comprising up to 19 printing and finishing units.

Today’s large-format series Rapida 145 and 164 are the successors to the Rapida 142 and 162 presses which were developed jointly by the Radebeul design engineers and their colleagues from Würzburg in the 1990s. In printshops around the world, these high-performance large-format presses took the place of presses from other manufacturers and paved the way for KBA-Sheetfed’s leading position in large formats. This standing was confirmed yet again in 2003 with the unveiling of the Rapida 205, the world’s largest sheetfed offset press.

Pioneer of new technologies

Pioneer of new technologies

In the same way that the Würzburg engineers ventured new approaches to webfed printing, the Saxon designers have repeatedly struck out on their own in search of simpler and more efficient sheetfed solutions. Two examples are the DI offset press 74 Karat with direct on-press plate imaging, which was developed together with Scitex from Israël in 1997, and its sister press Rapida 74 G from 2000. Both were equipped with short-train inking units for waterless printing. KBA remains strongly committed to this technology, which is especially interesting from the perspectives of print quality and environmental protection.

When it comes to innovative processes for inline finishing, ecological printing, direct printing on corrugated board or – most recently – LED-UV drying, KBA Sheetfed has regularly acted as a pioneer. The entry into the post-press market in 2016 and the announcement of the digital sheetfed press VariJET 106 at drupa open up further prospects.

World first in webfed printing

The era of web offset presses from Würzburg began with the Commander in 1969. Over time, the still dominant satellite design principle was becoming increasingly complex. At the beginning of the 1990s, this trend was answered with the four-high tower presses Journal and Colora. Later, they were joined by the single-width series Comet and Continent. The less expensive four-high tower design appealed to many new international customers, and helped to establish the company as the number one in newspaper printing.

In this field, too, the Würzburg engineers have never shied the pursuit of new ideas. Already at drupa 1995, for example, visitors could admire an Anilox-Express with automatic plate changing and an imprinter with Scitex inkjet heads in the superstructure. It was shown adding a variable digital caricature to each offset copy. It was then almost 18 years, however, before the inkjet technology was actually used in practice in webfed offset presses.

At drupa 2000, a new trend towards compact highly automated newspaper presses was heralded by the KBA Cortina, which stood less than 4 metres high. Further features new to newspaper offset were the elimination of dampening units, four-high towers which glided apart for easy access, dedicated drives for each cylinder and the ease of operation with lifts to the upper couples of the tower. The same concept was implemented by the wet offset counterpart Commander CT in 2007. Both presses have remained unique on the market to this day.

Media upheavals and realignment

Already in the early 1990s, the World Wide Web was taking its first tentative steps and new digital competitors entered the print arena. Faced with growing online competition, and especially due to the world financial crisis, the market for new webfed offset presses collapsed dramatically in 2008. Koenig & Bauer responded by turning attention to the digital process from 2011, and presented its first inkjet web press, the RotaJET 76, at drupa 2012. Today, with the RotaJET VL series for decor printing and the T1100 S manufactured on behalf of the American HP Corporation for the production of corrugated packaging, the largest digital web presses in the world are produced in Würzburg.

Early diversification

The company Koenig & Bauer went public in 1985. The acquisition of Albert-Frankenthal AG and of a majority stake in Planeta Druckmaschinenwerke in the early 1990s established a company group with a turnover of more than DM 1.1 billion. From the turn of the century onwards, the group management started a programme of diversification into market segments less affected by changes in the media landscape.

The acquisition of Swiss partner De La Rue Giori SA in Lausanne in 2001 secured KBA’s pole position in banknote printing. The purchase of Metronic GmbH in 2004 opened the door to the important market for industrial coding systems. The acquisitions of Bauer + Kunzi and LTG Print Systems, and the subsequent merger into KBA-MetalPrint GmbH in 2006, established KBA as the number one in metal decorating. And with KBA-Kammann GmbH as a global leader for the decoration of glass containers, alongside flexible packaging specialist KBA-Flexotecnica S.p.A, KBA has since 2013 further expanded its portfolio for the diverse packaging segment. A similar purpose was served by the takeover of Spanish die-cutter manufacturer Iberica in 2016.

This early diversification has helped KBA to master the structural upheavals which have rocked the branch much better than other press manufacturers. At the turn of the century, 60 per cent of the turnover from new press sales was still generated in market segments under pressure from the online media. Today, 90 per cent is accounted for by the growth markets digital and packaging printing and by securities printing.

Print technologies for every eventuality

Through market-oriented capacity realignment, the introduction of a new group structure and a clear focus on future-oriented markets, structural changes implemented in 2014 and 2015 have prepared the oldest press manufacturer in the world to meet the challenges of advancing digitisation and globalisation.

Today, analogue and digital KBA technologies are used to print, finish and process products such as banknotes, metal cans, books, brochures, displays, decor, labels, glass and plastic containers, board and film packaging, catalogues, laminates, magazines, tyres, cables, smart cards, advertising flyers, newspapers and many more besides. Practically all common printing and finishing technologies are involved. This diversity creates unique know-how, and continues to drive innovations, new applications and new partnerships.

Lees verder....This year KBA will celebrate that fact that Friedrich Koenig and Andreas Bauer started their first print press manufacturing plant in 1817. The history of KBA is also the history of our industry. The first cilinder press which left the plant in Oberzeil was the start of the industrialisation of the graphic industry which resulted in the super automated wide format offset presses and digital production printers which are now being installed in great numbers, thanks to the revival of print.

KBA plays, just like 200 years ago, a big role in this revival. It invented a number of unique concepts such as the superfast Condor press, and the Cortina waterless offset newspaper rotation press. The wide format solutions which KBA offers with their Rapida series and the T1100 S widest digital packaging press which they developed together with HP, are making history.

A history which was not always successful from a business point of view. The DI Karat direct imaging offset press with onpress imaging is an example. But it shows that KBA was not afraid to invest in specific market segments. This courage made them market leaders in segments such as wide format packaging, tinprinting and banknotes.

KBA´s history is also my personal history in this industry. The Gala, made by Albert Frankthal which later became part of KBA, was the first mid-sized high speed letterpress I got to work with when I was apprentice book printer. And the Condor was the fastest midsize format press that I worked with in the previous millennium.

When I was a journalist for PERS I was in 2013 invited to the introduction of the Rapida 164 super wide format offset press. An unforgettable experience to see how this printingmonster changed plates and get up to speed within minutes printing up to 18,000 prints per hour.

Congratulations to KBA are definitely in order and we are looking forward to seeing new developments in our industry thanks to pioneers such as KBA.

Read the full history of KBA below.

200 years Koenig & BauerInnovation-lined road from the first cylinder press to digital print

In August 2017, Koenig & Bauer AG (KBA) in Würzburg will be celebrating its 200th anniversary. The world’s first press-building workshop of 1817 has since blossomed into a globally successful manufacturing group with a unique portfolio of solutions for the printing industry. Anniversary festivities are planned from 21st to 23rd September – an ideal occasion to review past achievements and to present the visions which will determine the company’s strategy and market position in the third century of its history.

29th November 1814: The London “Times” was the first newspaper to be printed on the double-cylinder press designed by Friedrich Koenig and Andreas Bauer

Breakthrough in London

The times have certainly changed. In the early 19th century, Germany still lacked venturesome investors and a fertile industrial environment. It was not least for this reason that trained printer and untiring inventor Friedrich Koenig travelled to London in 1807 to realise his idea of a steam-driven printing press. While there, he met precision engineer Andreas Bauer, and in November 1814, The Times became the first newspaper to be printed on their double-cylinder press. This laid the foundations for printing on an industrial scale and for access to print media for a much broader section of the population.

Production in a former monastery

On 9th August 1817, Friedrich Koenig and Andreas Bauer signed a contract establishing Schnellpressenfabrik Koenig & Bauer in a secularised monastery in Oberzell near Würzburg, and in 1823, the Haude und Spenersche Zeitung in Berlin was the first newspaper on the European continent to be printed on presses from Oberzell.

Friedrich Koenig died in 1833. His widow Fanny Koenig and his former business partner Andreas Bauer continued his work. New presses were developed and the one-hundredth press was already delivered in 1838. A number of ambitious young workers moved away to found their own businesses. In this sense, Oberzell can be considered the cradle of German printing press manufacture. The company’s foundation period came to an end with the death of Andreas Bauer in 1860.

Early social achievements

The founder’s two sons, Wilhelm Koenig and Friedrich Koenig Jr., developed new presses, modernised factory routines and introduced a series of social reforms. The sickness benefit fund founded in 1855 was followed by a factory savings bank in 1865 and by a factory training school, the precursor of today’s vocational training centre in Würzburg, in 1868. The factory statute of 1873 defined the rights and duties of workers and managers and established a factory council ‒ employee participation already 140 years ago.

1876: The era of web printing begins

The first webfed press was supplied to a newspaper in Magdeburg in 1876. Wilhelm Koenig invented the variable web press in 1886, designed the first four-colour press in 1888, and began building special machines for the printing of luxury products. At the same time, he became very interested in securities printing, a field in which Koenig & Bauer was later to become technology leader. In 1895, the 5000th cylinder press left the factory.

From 1895 and through into the 1920s, the course of the company was shaped by Constantin Koenig and the founder’s grandson Albrecht Bolza. In 1901, a new factory was built at the site today occupied by the company headquarters. The 225 metre long production hall was one of the largest in Germany at that time. Webfed publication and rotogravure presses were manufactured, and the development of sheetfed machines was stepped up. Alongside printing presses, various matrix-moulding presses and plate-casting machines were delivered to customers all over the world.

Destruction and rebuilding

After the First World War, Dr. Hans Bolza, a great-grandson of Friedrich Koenig, made a notable contribution to the mending of severed foreign business links. He was appointed to the executive board of the company when it was transformed into a limited company in 1920 and served as chairman of the board from 1931 to 1971.

Koenig & Bauer survived the period of hyperinflation in the 1920s thanks to the newly developed Iris collect press for coloured banknotes. In March 1945, bombs and artillery shells destroyed the Würzburg factories. Reconstruction began in 1946. After the post-war currency reform, Koenig & Bauer resumed business in 1949 with nominal capital amounting to DM 4.1 million.

1952: Success story of security printing

Cooperation with securities printing expert Gualtiero Giori began in 1952. A further important milestone was the arrival of a talented young design engineer named Dr. Hans-Bernhard Schünemann, the son of a Bremen publishing family, in 1951. His first of over 250 patents was granted for a modification of the so called Maltese cross drive mechanism, which was subsequently used in another of his inventions, the sheetfed gravure press Rembrandt MT III. In 1959, Dr. Hans Bolza formally adopted Dr. Schünemann.

Dr. Bolza-Schünemann was himself president of Koenig & Bauer AG for almost 25 years from 1971 to 1995, and initiated the formation of the KBA Group from 1990. Executive responsibility was subsequently placed in the hands of his close partner and long-serving financial director Reinhart Siewert. After the turn of the century, he was succeeded by Albrecht (2003 – 2009) and Claus Bolza-Schünemann (since 2011), who thus represent the sixth generation of the founding family at the helm of the company.

Dr. Hans Bolza † (CEO from 1931 to 1971) and Dr. Hans-Bernhard Bolza-Schünemann † (CEO from 1971 to 1995)

Successful presses Condor and Rotafolio

Despite the growing offset competition in the 1960s and 70s, Koenig & Bauer retained the proven letterpress technology for its sheetfed and webfed presses for a relatively long time. Alongside the Rembrandt sheetfed gravure press and banknote presses developed together with De La Rue Giori, the two-revolution Condor and the Rotafolio sheetfed press for wrap-around plates were extremely successful all over the world.

High-performance in sheetfed offset since 1974

The first sheetfed offset press, the half-format Koebau-Rapida 0, was presented at drupa in 1967. The medium-format Koebau-Rapida III followed in 1969. Both ran at speeds up to 8,000 sheets per hour. The Koebau-Rapida SR III launched in 1974 was almost twice as fast at 15,000 sheets per hour. The presses of other major manufacturers did not achieve such performance until much later.

In 1986, Koenig & Bauer launched the Rapida 104, a unit-type press designed for high flexibility and printing speeds up 15,000 sheets per hour. Production was transferred to the new subsidiary KBA-Planeta AG in 1992, sowing the seed for today’s high-performance sheetfed offset presses from Radebeul. The current Rapida 106, for example, has defined the benchmarks in medium format with speeds up to 20,000 sheets per hour, extremely fast job changeovers and configurations comprising up to 19 printing and finishing units.

Today’s large-format series Rapida 145 and 164 are the successors to the Rapida 142 and 162 presses which were developed jointly by the Radebeul design engineers and their colleagues from Würzburg in the 1990s. In printshops around the world, these high-performance large-format presses took the place of presses from other manufacturers and paved the way for KBA-Sheetfed’s leading position in large formats. This standing was confirmed yet again in 2003 with the unveiling of the Rapida 205, the world’s largest sheetfed offset press.

Pioneer of new technologies

In the same way that the Würzburg engineers ventured new approaches to webfed printing, the Saxon designers have repeatedly struck out on their own in search of simpler and more efficient sheetfed solutions. Two examples are the DI offset press 74 Karat with direct on-press plate imaging, which was developed together with Scitex from Israel in 1997, and its sister press Rapida 74 G from 2000. Both were equipped with short-train inking units for waterless printing. KBA remains strongly committed to this technology, which is especially interesting from the perspectives of print quality and environmental protection.

When it comes to innovative processes for inline finishing, ecological printing, direct printing on corrugated board or – most recently – LED-UV drying, KBA Sheetfed has regularly acted as a pioneer. The entry into the post-press market in 2016 and the announcement of the digital sheetfed press VariJET 106 at drupa open up further prospects.

World first in webfed printing

The era of web offset presses from Würzburg began with the Commander in 1969. Over time, the still dominant satellite design principle was becoming increasingly complex. At the beginning of the 1990s, this trend was answered with the four-high tower presses Journal and Colora. Later, they were joined by the single-width series Comet and Continent. The less expensive four-high tower design appealed to many new international customers, and helped to establish the company as the number one in newspaper printing.

In this field, too, the Würzburg engineers have never shied the pursuit of new ideas. Already at drupa 1995, for example, visitors could admire an Anilox-Express with automatic plate changing and an imprinter with Scitex inkjet heads in the superstructure. It was shown adding a variable digital caricature to each offset copy. It was then almost 18 years, however, before the inkjet technology was actually used in practice in webfed offset presses.

At drupa 2000, a new trend towards compact highly automated newspaper presses was heralded by the KBA Cortina, which stood less than 4 metres high. Further features new to newspaper offset were the elimination of dampening units, four-high towers which glided apart for easy access, dedicated drives for each cylinder and the ease of operation with lifts to the upper couples of the tower. The same concept was implemented by the wet offset counterpart Commander CT in 2007. Both presses have remained unique on the market to this day.

Media upheavals and realignment

Already in the early 1990s, the World Wide Web was taking its first tentative steps and new digital competitors entered the print arena. Faced with growing online competition, and especially due to the world financial crisis, the market for new webfed offset presses collapsed dramatically in 2008. Koenig & Bauer responded by turning attention to the digital process from 2011, and presented its first inkjet web press, the RotaJET 76, at drupa 2012. Today, with the RotaJET VL series for decor printing and the T1100 S manufactured on behalf of the American HP Corporation for the production of corrugated packaging, the largest digital web presses in the world are produced in Würzburg.

Early diversification

The company Koenig & Bauer went public in 1985. The acquisition of Albert-Frankenthal AG and of a majority stake in Planeta Druckmaschinenwerke in the early 1990s established a company group with a turnover of more than DM 1.1 billion. From the turn of the century onwards, the group management started a programme of diversification into market segments less affected by changes in the media landscape.

The acquisition of Swiss partner De La Rue Giori SA in Lausanne in 2001 secured KBA’s pole position in banknote printing. The purchase of Metronic GmbH in 2004 opened the door to the important market for industrial coding systems. The acquisitions of Bauer + Kunzi and LTG Print Systems, and the subsequent merger into KBA-MetalPrint GmbH in 2006, established KBA as the number one in metal decorating. And with KBA-Kammann GmbH as a global leader for the decoration of glass containers, alongside flexible packaging specialist KBA-Flexotecnica S.p.A, KBA has since 2013 further expanded its portfolio for the diverse packaging segment. A similar purpose was served by the takeover of Spanish die-cutter manufacturer Iberica in 2016.

This early diversification has helped KBA to master the structural upheavals which have rocked the branch much better than other press manufacturers. At the turn of the century, 60 per cent of the turnover from new press sales was still generated in market segments under pressure from the online media. Today, 90 per cent is accounted for by the growth markets digital and packaging printing and by securities printing.

Print technologies for every eventuality

Through market-oriented capacity realignment, the introduction of a new group structure and a clear focus on future-oriented markets, structural changes implemented in 2014 and 2015 have prepared the oldest press manufacturer in the world to meet the challenges of advancing digitisation and globalisation.

Today, analogue and digital KBA technologies are used to print, finish and process products such as banknotes, metal cans, books, brochures, displays, decor, labels, glass and plastic containers, board and film packaging, catalogues, laminates, magazines, tyres, cables, smart cards, advertising flyers, newspapers and many more besides. Practically all common printing and finishing technologies are involved. This diversity creates unique know-how, and continues to drive innovations, new applications and new partnerships.

Lees verder.... Van 25 t/m 28 september is Brussel Expo de plaats waar meer dan 600 exposanten de nieuwste ontwikkelingen op label- en verpakkingsdruk zullen laten zien. De registratie voor deze beurs is nu geopend. Tot 15 september kost de entree 55 euro, daarna is de prijs 80 euro (standhouders hebben een beperkt aantal registratiecodes voor gratis kaarten beschikbaar).

Van 25 t/m 28 september is Brussel Expo de plaats waar meer dan 600 exposanten de nieuwste ontwikkelingen op label- en verpakkingsdruk zullen laten zien. De registratie voor deze beurs is nu geopend. Tot 15 september kost de entree 55 euro, daarna is de prijs 80 euro (standhouders hebben een beperkt aantal registratiecodes voor gratis kaarten beschikbaar).

Lees meer over deze specialistische vakbeurs in onderstaand persbericht.

PERSBERICHT

REGISTRATIONS FOR LABELEXPO EUROPE 2017 NOW OPEN

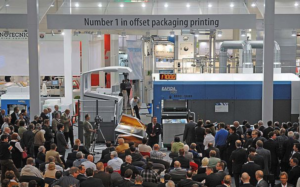

Online visitor registration is now open as Labelexpo Europe 2017 gears up for its biggest edition to date. The four-day trade show returns to Brussels Expo during 25 – 28 September, with over 650 exhibitors lining-up to showcase the latest in cutting-edge developments for the label printing market.

Aimed at printers, brand owners, label, packaging and graphic designers, Labelexpo Europe is the largest all-inclusive trade fair for label and package printing professionals. Creating a buzz of excitement within the industry, the show will cover an unprecedented total of nine exhibition halls. Buyers attending the show will be able to sample the newest tech and next generation materials from 106 new exhibitors and Labelexpo regulars including: HP Indigo, Avery Dennison, Bobst, Codimag, Domino, Durst, EFI, Epson, Esko, Flint Group, FUJIFILM, Gallus, Konica Minolta, Mark Andy, MPS, Nilpeter, Omet, Ritrama, Screen Europe, SPGPrints, Sun Chemical, UPM Raflatac and Xeikon.

A brand new special feature, the Automation Arena, will make its debut. Showing two automated press lines for digital and conventional label production, the Automation Arena is a practical workshop where visitors will discover how information management, integrated workflow, production automation and robotics are all working towards changing the performance and economics of the label and package printing plant of the future. The Linerless Trail will return to this year’s show with a particular focus on in-house production and new materials. In addition, the Label Academy will run master classes on shrink sleeves and MIS and workflow alongside an in-depth workshop on inks and coatings.

Jade Grace, Labelexpo Europe’s project director said: “Labelexpo’s goal is to make new technologies easy to understand, easy to buy and easy to adopt. Technology, its applications and materials are developing so rapidly in terms of innovation, performance and sustainability, that it is an absolute necessity for printers to have the very best possible and most up-to-date information to help guide their business strategy. As well as being able to meet the industry’s leading manufacturers and source new supply chain partners, Labelexpo Europe visitors will be able to see, compare and ultimately decide what new services and solutions they can implement themselves to reap the benefits of working smarter, more efficiently and more profitably.”

An early bird discount rate is now available until 15 September with show entry costing € 55. Visitors can register online and find out more about the show at: www.labelexpo-europe.com.

Lees verder.... From 25 to 28 September the Brussel Expo will be host to more than 600 exhibitors who will show the latest developments in label and packaging. Registration is now open. Entry tickets will be 55€ until 15 September, after that the price will be 80€ (exhibitors have a limited number of free ticket registration codes available).

From 25 to 28 September the Brussel Expo will be host to more than 600 exhibitors who will show the latest developments in label and packaging. Registration is now open. Entry tickets will be 55€ until 15 September, after that the price will be 80€ (exhibitors have a limited number of free ticket registration codes available).

Read more about this specialist tradeshow in the press release below.

REGISTRATIONS FOR LABELEXPO EUROPE 2017 NOW OPEN

Online visitor registration is now open as Labelexpo Europe 2017 gears up for its biggest edition to date. The four-day trade show returns to Brussels Expo during 25 – 28 September, with over 650 exhibitors lining-up to showcase the latest in cutting-edge developments for the label printing market.

Aimed at printers, brand owners, label, packaging and graphic designers, Labelexpo Europe is the largest all-inclusive trade fair for label and package printing professionals. Creating a buzz of excitement within the industry, the show will cover an unprecedented total of nine exhibition halls. Buyers attending the show will be able to sample the newest tech and next generation materials from 106 new exhibitors and Labelexpo regulars including: HP Indigo, Avery Dennison, Bobst, Codimag, Domino, Durst, EFI, Epson, Esko, Flint Group, FUJIFILM, Gallus, Konica Minolta, Mark Andy, MPS, Nilpeter, Omet, Ritrama, Screen Europe, SPGPrints, Sun Chemical, UPM Raflatac and Xeikon.

A brand new special feature, the Automation Arena, will make its debut. Showing two automated press lines for digital and conventional label production, the Automation Arena is a practical workshop where visitors will discover how information management, integrated workflow, production automation and robotics are all working towards changing the performance and economics of the label and package printing plant of the future. The Linerless Trail will return to this year’s show with a particular focus on in-house production and new materials. In addition, the Label Academy will run master classes on shrink sleeves and MIS and workflow alongside an in-depth workshop on inks and coatings.

Jade Grace, Labelexpo Europe’s project director said: “Labelexpo’s goal is to make new technologies easy to understand, easy to buy and easy to adopt. Technology, its applications and materials are developing so rapidly in terms of innovation, performance and sustainability, that it is an absolute necessity for printers to have the very best possible and most up-to-date information to help guide their business strategy. As well as being able to meet the industry’s leading manufacturers and source new supply chain partners, Labelexpo Europe visitors will be able to see, compare and ultimately decide what new services and solutions they can implement themselves to reap the benefits of working smarter, more efficiently and more profitably.”

An early bird discount rate is now available until 15 September with show entry costing €55. Visitors can register online and find out more about the show at www.labelexpo-europe.com.

Lees verder.... Van Eck & Oosterink Printendruk en De Groot – grootsgedrukt.nl hebben overeenstemming bereikt over een strategische samenwerking. Beide partijen hebben afgesproken samen in te spelen op vragen uit de markt, waar Van Eck & Oosterink digitaal drukwerk produceert, drukt De Groot het offsetdrukwerk van klein tot grootformaat.

Van Eck & Oosterink Printendruk en De Groot – grootsgedrukt.nl hebben overeenstemming bereikt over een strategische samenwerking. Beide partijen hebben afgesproken samen in te spelen op vragen uit de markt, waar Van Eck & Oosterink digitaal drukwerk produceert, drukt De Groot het offsetdrukwerk van klein tot grootformaat.

Autonome samenwerking

De Groot – grootsgedrukt.nl streeft naar de hoogste kwaliteit drukwerk – van standaard tot exclusief. Het feit dat het bedrijf een breed en volledig drukwerkpakket levert en de mogelijkheid heeft tot het drukken van planodrukwerkvellen, heeft ertoe bijgedragen de samenwerking aan te gaan met het familiebedrijf, vertelt directeur René van Eck. “Om onze ambitie naar onze klanten waar te maken, hebben we de beste partner nodig. Zij zijn het verlengstuk van onze dienstverlening. Samen maken we waar wat we beloven. Daarbij blijven wij als autonome partij in de markt drukwerk aanbieden, maar vindt een deel van onze productie plaats op de persen bij De Groot”, aldus René.

René: “Wij streven naar een samenwerking met een langetermijndoelstelling. Kritisch blijven naar elkaar, knelpunten bespreken en deze oplossen waar nodig; het maakt beide partijen sterker. Als De Groot als onze partner het goed doet, doen wij het ook goed en komt de klant graag bij ons terug. Dit effect is enorm belangrijk.”

Durven investeren

Wim Everts, algemeen directeur De Groot – grootsgedrukt.nl, vertelt dat innovatie hoog in het vaandel staat. Naast nieuwe persen investeert de drukkerij tevens in automatiseringsoplossingen, om in de nabije toekomst de klant efficiënt te blijven bedienen. Zeker ook als het gaat om het bestellen van online drukwerk via de webshop grootsgedrukt.nl, white label-toepassingen of via XML-integraties. Zo gaan De Groot – grootsgedrukt.nl en Van Eck & Oosterink samen aan de slag om bedrijven in Nederland op effectieve wijze te bedienen.

Over Van Eck & Oosterink

Van Eck & Oosterink bestaat uit twee verschillende bedrijven, met ieder hun eigen discipline. Een drukkerij, Printendruk en een communicatiebureau met de naam: Communicatieregisseurs. Bij de laatste ligt de focus op strategie, marketing en communicatie. “Onze handen jeuken om bedrijven in het zonnetje te zetten, ze aandacht te geven en met pakkende fotografie en slimme teksten hun verhaal te vertellen. We zorgen voor een website die goed gevonden wordt, een spraakmakende advertentiecampagne of schitterende magazines, die vanaf heden door De Groot – grootsgedrukt.nl gedrukt worden”, aldus René.

De nieuwe iMac Pro en de HomePod stelen misschien wel de show op de WWDC 2017, maar het grootste nieuws van Apple zit “onder de motorkap.”

De nieuwe iMac Pro en de HomePod stelen misschien wel de show op de WWDC 2017, maar het grootste nieuws van Apple zit “onder de motorkap.”

Op zich simpele zaken, zoals: een file manager, drag and drop en een full size digitaal keyboard voor de nieuwe iPad Pro, lijken niet spectaculair, maar maken van de tablet wel een veel beter gereedschap voor professionele toepassingen, zoals: foto-editing en paginaopmaak.

Net zoals het nieuwe Apple filesystem (met instant dupliceren ook van grotere files) en de toepassing van Metal, zoals de turbo voor graphics en video (tot 10 x sneller), zal het nieuwe OS voor Mac, High Sierra, een Mac-gebruiker productiever maken en het werken met een Mac veraangenamen.

Superieure hardware

Apple heeft zijn hardware niet vergeten, de nieuwe supersnelle processoren en de mogelijkheid om meer werkgeheugen te plaatsen maken, samen met de nieuwe beeldschermen, van de hele lijn weer superieure hardware.

Vooral de nieuwe beeldschermen met een nog groter kleurbereik en verbeterde helderheid, zullen indruk maken op potentiële klanten. Die zullen de snelheid van beeldopbouw waarderen en een nieuwe benchmark voor grafische werkstations zien.

Dat Apple veel producten in prijs verlaagd heeft, en dat ze direct leverbaar zijn, zal ongetwijfeld invloed hebben op de omzet van Apple en de koopbereidheid van klanten in de komende maanden.

Wachten is nu nog op de nieuwe iPhone die, naar verwachting in het najaar, zijn eigen event zal krijgen. Als de specificaties daarvan in de buurt komen van concurrenten of die overtreffen, zal Apple, ondanks de kritiek van velen, het jaar toch weer goed afsluiten.

The new iMac Pro and the Homepod may be stealing the show, but the biggest Apple news is located under the hood.

The new iMac Pro and the Homepod may be stealing the show, but the biggest Apple news is located under the hood.

Things that are relatively simple such as a file manager, drag and drop, and a full size digital keyboard for the new iPad Pro do not appear spectacular, but make the tablet a much better tool for professional applications such as photo editing and page editing.

Just like the new Apple filing system (with instant duplication also for bigger files) and the application of Metal as turbo for graphics and video (up to 10 times faster) the new Mac OS, High Sierra, will make the Mac user more productive and further enhance working with a Mac.

Superior hardware

Apple has not forgotten the hardware. The new superfast processors and the possibility to add work memory, together with the new screens will make the whole line superior.

Especially the new screens with greater colour reach and improved clarity will make an impression on potential clients. They will appreciate the speed of the colour build-up and see a new benchmark for graphic work stations.

The fact that Apple has lowered many of the prices and the fact that the products are immediately available will undoubtedly also influence Apple´s turnover and customers´ willingness to buy.

We are now waiting for the new iPhone which is expected to get its own event this autumn. If its specifications are close to those of its competitors, or possibly even exceed those, Apple will finish the year on a high-note despite criticism.

Lees verder....

De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK