Rob van den Braak

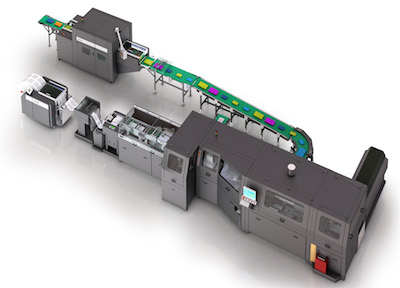

Rotomail has invested in a second Tecnau Libra 800 soft-cover book binding system to expand its production capacity for short runs and book on demand.

Rotomail has invested in a second Tecnau Libra 800 soft-cover book binding system to expand its production capacity for short runs and book on demand.

Rotomail was established in 1996 as a Print on Demand service provider. In 2000 the company became one of the first adopters of inkjet technology, introducing color and developing trans-promotional applications. In 2003 Rotomail started diversifying into direct mail, commercial print and books market segments, and contributed to the development of the first Libra 800. In 2016 Rotomail installed the new HP T490 inkjet HDNA press, becoming the first user worldwide of High Definition Nozzle Architecture.

In the Milan-based factory, rolls will be printed on the HP PageWide presses and finished nearline on Libra 800 in a roll-to-finished-book integrated process.

The modular system has been configured by Rotomail with one input channel from roll, along with slit merge and dual web cutter to produce variable book-blocks in height, width and thickness.

Variable book blocks are automatically delivered to Libra VB Variable Binder connected online to Libra VT Variable Three-Knife Trimmer. The system feeds covers from roll and cuts them down in length and width with spine scoring according to the book block being processed, for complete variability book by book in the same run, minimized waste and without manual handling.

The finishing process is integrated with Rotomail proprietary software “Bronte” providing a complete process control including order entry, production optimization and output tracking.

The Tecnau Libra 800 integrates a networked management system for process control, remote diagnostics, statistical evaluations and integration to other solutions, bringing the IoT (Internet of Things) within the realm of industrial applications for smart manufacturing.

“Tecnau is honored by the continuing Rotomail partnership as we strive to be ahead of the technology curve in book finishing. Rotomail provided a brilliant contribution to the original Libra 800 design back in 2008, and we are proud that after eight years they judge that the continuous development of Libra 800 makes it still the leading book-binding technology in the market for short runs and book-of-one production” comments Stefano De Marco, Tecnau Sales & Marketing Director EMEA.

Tecnau Libra 800 advantages go beyond efficient and flexible printing. Tecnau aims for the Libra 800 to completely transform book production for short runs and book on demand production.

Libra 800 makes it possible to reorganize book production workflow by printing only the books actually sold, producing books by contract rather than by format, significantly reducing inventory and optimizing logistics. Market insights indicate that book printers are increasingly averaging run lengths between 250 and 500 copies, up from averages around 700-1000 copies per run only two years ago, and 1500-3000 copies five years ago.

If that trend continues, a solution especially developed for short-run or book of one production will be the best investment to meet current needs and anticipate future market developments. There are also other segments where book of one or short-run productions are an opportunity, for example, certain catalogs, limited editions, custom books, self-publishing and more in general, publications collected by web-to-print portals.

The Libra 800 solution is the only system on the market together offering such levels of variability while maintaining production speed up to 800 books/hour.

Lees verder....

Trends that concern print shops at the moment are smaller editions, shorter delivery times and order growth. No surprise therefore that digital has become an important factor for print shops next to traditional offset. Four out of ten commercial printers say that a quarter or more of their turnover comes from digital. This is 14% for packaging, 22% for publishers and 62% for industrial graphic print shops.

Trends that concern print shops at the moment are smaller editions, shorter delivery times and order growth. No surprise therefore that digital has become an important factor for print shops next to traditional offset. Four out of ten commercial printers say that a quarter or more of their turnover comes from digital. This is 14% for packaging, 22% for publishers and 62% for industrial graphic print shops.However, the makers of the recent drupa report say that digital is not advancing as fast as expected. Although everyone expected that the transition to digital was continuing, for the first time there was a slight, but noticeable, decline in digital´s part in turnover.

Remarkable also is the fact that the growth of variable data isn´t pushing through. In 2013 19% of printers who do both digital and offset said that more than 25% of digital was variable print. In 2016 this was “only” 18%.

All this from the 4th drupa Global Trends report 2017. A number of graphic print companies were surveyed: 839 print shops of which 525 from Europe, and 331 suppliers of which 220 from Europe. The complete report is available online for 249€.

Source: drupa

Lees verder....

Onlinegedrukt.nl, onderdeel van De Groot Drukkerij bv, is jaren geleden opgezet als webshop voor de VKGO, de vereniging van kleinere grafische ondernemingen in Nederland en een klein deel van België. Vanaf 1 april 2017 wordt onlinegedrukt.nl geïntegreerd in de nieuwe webshop van De Groot – grootsgedrukt.nl.

Onlinegedrukt.nl bood de kleine ondernemer, en tevens mediaspecialist, een overzichtelijke bestelomgeving voor haar drukwerk. Voor een breed pakket aan producten en diensten konden de VKGO-leden tegen aantrekkelijke prijzen hun drukwerk inkopen. Een apart portaal voor alleen de VKGO-leden is niet langer nodig, omdat De Groot hetzelfde kan bieden binnen de vernieuwde webshop grootsgedrukt.nl.

Grootsgedrukt.nl

Waar De Groot Drukkerij bv de afgelopen 50 jaar onder de naam De Groot Drukkerij het drukwerk leverde, doen we dat vanaf heden onder de naam De Groot – grootsgedrukt.nl. Klanten worden vanuit één naam, één gezicht en één portaal bediend. De toekomst is: grootsgedrukt.nl.

Vanaf 1 april 2017 wordt ook onlinegedrukt.nl opgenomen in deze nieuwe omgeving. De condities die gelden voor de VKGO-leden worden meegenomen bij deze integratie. Zo bieden we ook de VKGO-leden één website voor advies, inspiratie én het bestellen van al het drukwerk: grootsgedrukt.nl.

Blijven investeren

Het familiebedrijf is blijven investeren, ook in de mindere jaren. We hebben geïnvesteerd en gaan nog meer investeren in ons machinepark. Omsteltijden zijn met maar liefst 20% verkort, zodat verschillende batches elkaar sneller kunnen opvolgen. Het machinepark is uitgebreid met een 8 kleuren KBA Rapida pers. Deze offset machine haalt een drukwerksnelheid van maar liefst 18.000 vellen per uur en bundelt moeiteloos kleine orders. Daarmee worden de doorlooptijden aanzienlijk verkort.

De Groot – grootsgedrukt.nl ontzorgt op het gebied van druk- en printwerk op hoogwaardig niveau. Ook in de toekomst willen we de VKGO-leden een warm hart toedragen door voordeel te bieden bij de inkoop van drukwerk via grootsgedrukt.nl.

Met trots: Groots gedaan in Goudriaan!

Lees verder....

A lot has been written about the environmentally friendly role digital printed packaging can play. In Laurel Brunner´s blog she lists all pros and points out the importance of a good workflow to make a success of digital printing.

A lot has been written about the environmentally friendly role digital printed packaging can play. In Laurel Brunner´s blog she lists all pros and points out the importance of a good workflow to make a success of digital printing.

Lees verder....

Er is al veel geschreven over de milieuvriendelijke rol die digitaal geprinte verpakkingen kan spelen. In haar blog zet Laurel Brunner de argumenten ervoor nog eens op een rijtje en vraagt aandacht voor het belang van een goede workflow, om van digital printing een succes te maken. Lees haar blog op onze artikelenpagina via deze link.

Er is al veel geschreven over de milieuvriendelijke rol die digitaal geprinte verpakkingen kan spelen. In haar blog zet Laurel Brunner de argumenten ervoor nog eens op een rijtje en vraagt aandacht voor het belang van een goede workflow, om van digital printing een succes te maken. Lees haar blog op onze artikelenpagina via deze link.

Lees verder....

Volgens Paul Lindström besteden printers nog te veel tijd aan het afstemmen van printkleuren op verschillende media. Dat is volgens Paul echt niet nodig. In zijn Wild Format artikelen geeft hij de simpele stappen aan die veel tijd, materiaal en conflicten met klanten kunnen besparen. Lees zijn introductie via deze link.

Volgens Paul Lindström besteden printers nog te veel tijd aan het afstemmen van printkleuren op verschillende media. Dat is volgens Paul echt niet nodig. In zijn Wild Format artikelen geeft hij de simpele stappen aan die veel tijd, materiaal en conflicten met klanten kunnen besparen. Lees zijn introductie via deze link.

Lees verder....

According to Paul Lindström print shops still devote too much time to finetuning print colours for different media. He reasons that this is absolutely not necessary. In his Wild Format editorial he suggests some simple steps which will save time, materials and prevent issues with the client. Read his tips via this link.

According to Paul Lindström print shops still devote too much time to finetuning print colours for different media. He reasons that this is absolutely not necessary. In his Wild Format editorial he suggests some simple steps which will save time, materials and prevent issues with the client. Read his tips via this link. Lees verder....

De Ghent Workgroup (GWG) meldt, dat Agfa’s Apogees Prepress workflow succesvol zijn certificatieproces heeft voltooid, en wel met het hoogste preflight testniveau wat een betrouwbare PDF processing garandeert.

De Ghent Workgroup (GWG) meldt, dat Agfa’s Apogees Prepress workflow succesvol zijn certificatieproces heeft voltooid, en wel met het hoogste preflight testniveau wat een betrouwbare PDF processing garandeert.

Het certificaat voor Agfa Graphic geldt ook voor Agfa’s eigen preflight software, dat onderdeel is van Apogee.

Lees meer over deze certificatie in onderstaand persbericht.

PERSBERICHT

Ghent Workgroup (GWG) announces, that Agfa’s Apogee Prepress workflow has successfully passed the latest GWG PDF preflight certification, addressing the highest level of preflight capability for reliable PDF processing. The certification gained by Agfa Graphics includes Agfa’s own preflighting software integrated in Apogee.

Ghent Workgroup (GWG) announces, that Agfa’s Apogee Prepress workflow has successfully passed the latest GWG PDF preflight certification, addressing the highest level of preflight capability for reliable PDF processing. The certification gained by Agfa Graphics includes Agfa’s own preflighting software integrated in Apogee.

The certification gained by Agfa includes the already-certified Enfocus PitStop preflighting software integrated in Apogee and adds Agfa’s own preflighting engine, ensuring that whichever option Apogee users select, they can be confident that their workflow will test incoming PDF files to the most rigorous level. Identifying potential output issues or file processing errors saves both time and materials, enabling printers to operate more productively and to identify recurring flaws in supplied artwork, so that both the creative and production workflows can be improved.

Erik Peeters, Marketing Manager Workflow Solutions, Agfa Graphics, commented on achieving the GWG certification: “Every day Apogee workflow systems worldwide process over one million PDF pages. Making sure that potential issues are detected early in the process is essential, so preflight has always been a key component of our workflow solutions. By using preflight profiles based on the GWG2015 specifications, our users can rely on a solid and proven set of checks that make sure final output meets their quality requirements.”

David Zwang, Chairman, Ghent Workgroup, points out: “As a globally recognized workflow vendor, Agfa has been a valued participant in GWG initiatives and standards and it has done a great job in passing the Ghent Workgroup PDF preflight certification. Agfa has taken an important step in supporting the latest specifications; this is beneficial to all graphic arts associations and to the industry itself who will eventually use and profit from the new preflight profiles in Agfa’s workflow solutions.”

Preflight for prepress quality control

The GWG2015 preflight certification is a validation of the prepress quality control specification, developed by the GWG. It contains 14 different ‘variants’ aimed at different print market segments and output methods, all based on the ISO PDF/X-4 standard, but with additional conditions and restrictions relevant to each segment. The variants cover the majority of common print applications and include web- and sheetfed CMYK and/or spot color, magazine and newspaper advertisements. Because the certification is based on the PDF/X-4 standard, it also includes variants which include the use of RGB colors within artwork files as well as ‘live’ transparency to support the most sophisticated and up-to-date graphic arts workflows.

The GWG2015 preflight certification is a validation of the prepress quality control specification, developed by the GWG. It contains 14 different ‘variants’ aimed at different print market segments and output methods, all based on the ISO PDF/X-4 standard, but with additional conditions and restrictions relevant to each segment. The variants cover the majority of common print applications and include web- and sheetfed CMYK and/or spot color, magazine and newspaper advertisements. Because the certification is based on the PDF/X-4 standard, it also includes variants which include the use of RGB colors within artwork files as well as ‘live’ transparency to support the most sophisticated and up-to-date graphic arts workflows.

The test suite used in the certification process comprises 260 test files that cover aspects such as correct detection of minimum image resolution, use of correct color spaces, white and grey overprint settings, ink coverage and spot color usage and naming. File content that does not meet the necessary conditions is either flagged with an error message or with a warning, depending on the importance of the issue and how it could affect output.

Didier Haazen, Senior Innovation Advisor, VIGC, elaborates: “The preflight certification does not only check ‘bad’ cases where errors or warnings should be flagged, but adds positive vetting of ‘good’ examples where no messages should be presented. The test set is the result of years of expertise and real-world experience. The use of so many test files allows for thorough checking against the GWG2015 preflight requirements. The procedure guarantees consistency between different preflight applications, which is a huge benefit for end-users when making comparisons and purchasing decisions.”

More info:

If you are interested in the GWG2015 preflight certification procedure and test files, please take a look at: http://www.gwg.org/compliancy-testing-procedure.

Information on the GWG2015 PDF/X workflow specification which underpins the preflight certification is available at: http://www.gwg.org/gwg-2015-pdfx-workflow/.

Agfa has also published a technote with guidelines on the use of the GWG2015 specifications with Apogee Prepress 10: https://www.agfagraphics.com/global/en/articles/tips-tricks/apogee-prepress-10-how-to-use-gwg-2015-preflight-profiles.html.

Ghent Workgroup (GWG) announces that Agfa’s Apogee Prepress workflow has successfully passed the latest GWG PDF preflight certification, addressing the highest level of preflight capability for reliable PDF processing. The certification gained by Agfa Graphics includes Agfa’s own preflighting software integrated in Apogee.

Ghent Workgroup (GWG) announces that Agfa’s Apogee Prepress workflow has successfully passed the latest GWG PDF preflight certification, addressing the highest level of preflight capability for reliable PDF processing. The certification gained by Agfa Graphics includes Agfa’s own preflighting software integrated in Apogee.

The certification gained by Agfa includes the already-certified Enfocus PitStop preflighting software integrated in Apogee and adds Agfa’s own preflighting engine, ensuring that whichever option Apogee users select, they can be confident that their workflow will test incoming PDF files to the most rigorous level. Identifying potential output issues or file processing errors saves both time and materials, enabling printers to operate more productively and to identify recurring flaws in supplied artwork so that both the creative and production workflows can be improved.

Erik Peeters, Marketing Manager Workflow Solutions, Agfa Graphics, commented on achieving the GWG certification: “Every day Apogee workflow systems worldwide process over one million PDF pages. Making sure that potential issues are detected early in the process is essential, so preflight has always been a key component of our workflow solutions. By using preflight profiles based on the GWG2015 specifications, our users can rely on a solid and proven set of checks that make sure final output meets their quality requirements.”

David Zwang, Chairman, Ghent Workgroup, points out: “As a globally recognized workflow vendor, Agfa has been a valued participant in GWG initiatives and standards and it has done a great job in passing the Ghent Workgroup PDF preflight certification. Agfa has taken an important step in supporting the latest specifications; this is beneficial to all graphic arts associations and to the industry itself who will eventually use and profit from the new preflight profiles in Agfa’s workflow solutions.”

Preflight for prepress quality control

The GWG2015 prefight certification is a validation of the prepress quality control specification developed by the GWG. It contains 14 different ‘variants’ aimed at different print market segments and output methods, all based on the ISO PDF/X-4 standard, but with additional conditions and restrictions relevant to each segment. The variants cover the majority of common print applications and include web- and sheetfed CMYK and/or spot color, magazine and newspaper advertisements. Because the certification is based on the PDF/X-4 standard, it also includes variants which include the use of RGB colors within artwork files as well as ‘live’ transparency to support the most sophisticated and up-to-date graphic arts workflows.

The GWG2015 prefight certification is a validation of the prepress quality control specification developed by the GWG. It contains 14 different ‘variants’ aimed at different print market segments and output methods, all based on the ISO PDF/X-4 standard, but with additional conditions and restrictions relevant to each segment. The variants cover the majority of common print applications and include web- and sheetfed CMYK and/or spot color, magazine and newspaper advertisements. Because the certification is based on the PDF/X-4 standard, it also includes variants which include the use of RGB colors within artwork files as well as ‘live’ transparency to support the most sophisticated and up-to-date graphic arts workflows.

The test suite used in the certification process comprises 260 test files that cover aspects such as correct detection of minimum image resolution, use of correct color spaces, white and grey overprint settings, ink coverage and spot color usage and naming. File content that does not meet the necessary conditions is either flagged with an error message or with a warning, depending on the importance of the issue and how it could affect output.

Didier Haazen, Senior Innovation Advisor, VIGC, elaborates: “The preflight certification does not only check ‘bad’ cases where errors or warnings should be flagged, but adds positive vetting of ‘good’ examples where no messages should be presented. The test set is the result of years of expertise and real-world experience. The use of so many test files allows for thorough checking against the GWG2015 preflight requirements. The procedure guarantees consistency between different preflight applications, which is a huge benefit for end-users when making comparisons and purchasing decisions.”

More info:

If you are interested in the GWG2015 preflight certification procedure and test files, please take a look at: http://www.gwg.org/compliancy-testing-procedure.

Information on the GWG2015 PDF/X workflow specification which underpins the preflight certification is available at: http://www.gwg.org/gwg-2015-pdfx-workflow/.

Agfa has also published a technote with guidelines on the use of the GWG2015 specifications with Apogee Prepress 10: https://www.agfagraphics.com/global/en/articles/tips-tricks/apogee-prepress-10-how-to-use-gwg-2015-preflight-profiles.html.

Printers are cautiously optimistic about their companies: 42% of printers says their company is doing well and only 11% say that business is bad. Nearly half (46%) of printers are expecting an improvement this year. Packaging and industrial printers are generally more positive than commercial printers. Printers who are also publishers are the least positive.

Printers are cautiously optimistic about their companies: 42% of printers says their company is doing well and only 11% say that business is bad. Nearly half (46%) of printers are expecting an improvement this year. Packaging and industrial printers are generally more positive than commercial printers. Printers who are also publishers are the least positive.Although printers and suppliers are relatively positive about the coming year, it is remarkable that expectations are moderate. Reason for these moderate expectations is the continuing decrease in price (and consequent lower margins) for the graphic industry. By supplementing income and more efficiency printers are able to compensate this.

Digital

The number of digital prints continues to rise. 40% of commercial printers says that a quarter of their sales is from digital. This is 14% for packaging, 22% for publishers and 62% for industrial graphic production companies.

The 4th drupa Global Trends Report 2017 has surveyed 839 printers of which 525 in Europe and 331 suppliers of which 220 in Europe. The complete report is available online for 249 Euro.

Source: drupa

Apart from its toner technology Xeikon will now also offer an inkjet solution. The Xeikon PX3000 is a UV inkjet production label printer with what Xeikon calls Panther technology. It is not clear which inkjet heads will be used, but mother company Flint will undoubtedly have offered its ink expertise. The inkjet UV technology will greatly increase the number of media which can now be used with Xeikon label printers. We think that cost price and productivity have also played a role in this, quite logical, extension of Xeikon´s portfolio.

Apart from its toner technology Xeikon will now also offer an inkjet solution. The Xeikon PX3000 is a UV inkjet production label printer with what Xeikon calls Panther technology. It is not clear which inkjet heads will be used, but mother company Flint will undoubtedly have offered its ink expertise. The inkjet UV technology will greatly increase the number of media which can now be used with Xeikon label printers. We think that cost price and productivity have also played a role in this, quite logical, extension of Xeikon´s portfolio.

Lees verder....

Naast zijn tonertechnologie gaat Xeikon nu ook een inkjetoplossing aanbieden. De Xeikon PX3000 is een UV inkjet production labelprinter met wat Xeikon Panther technologie noemt. Welke inkjet heads gebruikt worden is niet bekend, maar moederbedrijf Flint zal ongetwijfeld zijn expertise op het gebied van inkten ingebracht hebben. De inkjet UV techniek zal het aantal mediasoorten, dat met Xeikon labelpersen bedrukt kan worden, sterk uitbreiden. Ook kostprijs- en productiviteitvoordelen van inkjet zullen meegespeeld hebben bij deze logische uitbreiding van Xeikon’s portfolio.

Naast zijn tonertechnologie gaat Xeikon nu ook een inkjetoplossing aanbieden. De Xeikon PX3000 is een UV inkjet production labelprinter met wat Xeikon Panther technologie noemt. Welke inkjet heads gebruikt worden is niet bekend, maar moederbedrijf Flint zal ongetwijfeld zijn expertise op het gebied van inkten ingebracht hebben. De inkjet UV techniek zal het aantal mediasoorten, dat met Xeikon labelpersen bedrukt kan worden, sterk uitbreiden. Ook kostprijs- en productiviteitvoordelen van inkjet zullen meegespeeld hebben bij deze logische uitbreiding van Xeikon’s portfolio.

Lees verder....

De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK