Rob van den Braak

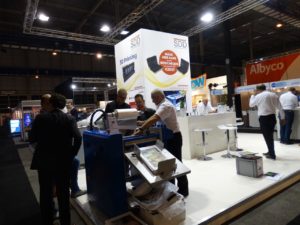

SPRINTIS, de grootste leverancier van grafische afwerkingsmaterialen in Europa, is nu voor de BeNeLux ook de officiële dealer van de hardcover apparatuur van de Duitse firma Schmedt. Al meer dan 100 jaar ontwikkelt en produceert Schmedt apparatuur voor boekbinderijen.

In de persoon van Paul Spitzen is deze Schmedt apparatuur de laatste 25 jaar in de BeNeLux-markt verkocht, en deze traditie zet zich nu voort bij de firma SPRINTIS die sinds eind vorig jaar nu ook met haar “SPRINTIS – Sales Office BeNeLux” – verkoopkantoor in Nederland actief is.

In de persoon van Paul Spitzen is deze Schmedt apparatuur de laatste 25 jaar in de BeNeLux-markt verkocht, en deze traditie zet zich nu voort bij de firma SPRINTIS die sinds eind vorig jaar nu ook met haar “SPRINTIS – Sales Office BeNeLux” – verkoopkantoor in Nederland actief is.

SPRINTIS Schenk GmbH & Co. KG is een zeer sterk- en snelgroeiende onderneming die in de grote Duitse drukkersmarkt al lang een groot marktleider is met materialen voor drukkerijen, boekbinderijen en voor de reclame-industrie (POS). Met meer dan 6.000 palletplaatsen levert SPRINTIS van busschroeven, magneten en WireBind tot zuignappen, wiebelaars en datumwijzers, vrijwel alles uit voorraad en dat tegen zeer concurrerende prijzen. Al deze producten zijn nu ook terug te vinden in de Nederlandstalige webshop van SPRINTIS.NL.

Vanuit een monumentaal pand staan Paul Spitzen en Frencis Hoogmoed als productspecialisten de klanten in de BeNeLux-markt ook telefonisch te woord. Met de komst van Paul Spitzen levert SPRINTIS.NL ook apparatuur in de BeNeLux.

De vertegenwoordiging van de Schmedt apparatuur was een logische keuze, door de kennis en een jarenlange ervaring op dit gebied.

Schmedt produceert apparatuur voor hardcover (harde band) kleine en medium oplagen. Door de trend van steeds kleinere producties is de vraag naar deze apparatuur groot.

Oplagen vanaf één boek zijn economisch te produceren, omdat de apparatuur meestal geen omsteltijden kent. Op deze wijze is het mogelijk zelfs tot 250 producten per uur, ieder van verschillend formaat, te produceren. Hierin is de apparatuur van Schmedt uniek.

Vrijwel alle producenten van fotoboeken, maar ook van digitaal geprinte en vaak ook gepersonaliseerde producties, klein tot middelgroot, maken gebruik van de apparatuur van Schmedt voor de productie van hardcover boeken.

Voor meer informatie kunt u contact opnemen met:

SPRINTIS – Sales Office BeNeLux

+ 31 (0)85 877 1356

www.sprintis.nl // info@sprintis.nl

Blokboek.com redactrice Beate den Engelsman bracht de eerste dag van de Grafische Vakbeurs & Vakbeurs Sign 2017 in beeld.

Klik op de foto om hem groter te zien en deel een foto met anderen met een van de share knoppen.

Lees verder....Anton De Groot, managing director of the print company of the same name, is extremely satisfied with the investment in an eight-colour KBA Rapida 106 with simultaneous plate changing for his production facility in the picturesque Dutch village of Goudriaan. “It seems as if the printers here are walking around with a smile on their face all day,” he notes with a wink.

Over the 50 years since its founding, De Groot has installed a whole armada of printing presses in small to large formats. Private and business stationery, magazines, books and advertising products make up the bulk of the work to be done. Many of the jobs handled are for the retail trade, for which De Groot also offers tailored promotional print packages. At the same time, no-one shies the challenge of some very exclusive orders.

“We take a very systematic approach whenever we are looking for new machinery,” says managing director Anton De Groot. “Our first closer contact with KBA’s sheetfed offset presses came at drupa 2012. Before then, KBA had not been on our shortlist.”

The new eight-colour Rapida 106 is the first KBA press at De Groot in Goudriaan

Speed is becoming increasingly important

The latest investment was prepared very thoroughly, and extensive analyses were performed to compare various presses from Germany and Japan. “In the premium segment, the differences are often only small, but speed is becoming increasingly important,” Anton De Groot explains. “You could liken it to a pit stop in Formula One racing, where every second counts. The top production speed – which on the eight-colour Rapida 106 means 18,000 sheets per hour in perfecting mode – was one of the deal-clinching factors. The choice of the B1 format and the extremely fast job changeover times were similarly essential for our production. Our market demands fast delivery times and products of the highest quality.”

The printers enjoy working at the modern console of their highly automated press

Training ahead of the installation

“After the successful acceptance tests in Radebeul, five lorries brought the press to the Netherlands, where it was installed by engineers from KBA and Wifac. We then carried out some further tests and the results were even better than what we had already seen in Radebeul. Remarkable. For our printers, the new press also meant quite a change in daily procedures, because they were accustomed to working on other presses. But a few of them were in Radebeul for training, and so we are confident that we will be able to draw maximum benefit from the new Rapida. About a month passed between the training and the arrival of the Rapida 106. To bridge this time, the printers came home with an interactive PDF which allowed them to practise on the computer – not to forget a certificate! They all enjoyed it very much.”

Every second counts today: The plates for the next job are already waiting on the press gallery

Growth through automated production

The long high-tech Rapida replaces an older eight-colour press and a B2 press. The significantly higher printing speed and the fast makeready of the Rapida 106 have boosted production capacity by approx. 40 per cent. Moreover, the range of substrates which De Groot is able to handle in perfecting has been expanded to cover grammages from approx. 60 to 500 gsm (0.6mm). The Rapida operates in three shifts, running at maximum speed for the most part. To support this performance, the whole press hall is arranged to ensure that plates, paper and ink (thanks to an automatic ink supply) can always be made available on time.

De Groot: “That is necessary to be able to implement our growth strategy. Run lengths are still decreasing, but the number of jobs has rocketed. Organisation and equipment must be geared to this situation, and we must move in the direction of full automation wherever possible. In the meantime, human intervention in the print process is the exception. That reduces the risk of mistakes. With the new press, we plan to increase our sales and secure the future of the company.”

In advance of the installation of the new Rapida, De Groot invested in expansion and modernisation of its CtP pre-press. Timely plate availability is thus guaranteed. In addition, a second logistics centre has been set up. “Our goal is maximum sustainability. Low waste, low emissions and the lowest possible material consumption are pillars of our corporate culture.”

After two months, Anton de Groot presents a positive first summary: “The Rapida 106 has exceeded all expectations. Both the printers and our customers are very happy. With KBA, we have found a press manufacturer who cares about our employees and our future.”

Lees verder....

De afdrukkwaliteit van groot formaat printers wordt niet alleen beïnvloed door zaken als de printkoppen, de kwaliteit van de inkt en de output resolutie. In zijn Wild Format artikel gaat Paul Lindström in op de eisen die een groot formaat printer stelt aan de vloer waarop hij staat, hoe belangrijk het is om per substraat de printsettingen aan te passen en de menselijke factor, c.q. vakmanschap, en hoe deze de afdrukkwaliteit kunnen verbeteren. Lees het artikel van Paul op onze artikelenpagina via deze link.

De afdrukkwaliteit van groot formaat printers wordt niet alleen beïnvloed door zaken als de printkoppen, de kwaliteit van de inkt en de output resolutie. In zijn Wild Format artikel gaat Paul Lindström in op de eisen die een groot formaat printer stelt aan de vloer waarop hij staat, hoe belangrijk het is om per substraat de printsettingen aan te passen en de menselijke factor, c.q. vakmanschap, en hoe deze de afdrukkwaliteit kunnen verbeteren. Lees het artikel van Paul op onze artikelenpagina via deze link.

Lees verder....

Print quality of wide format printers is not only influenced by things such as printheads, ink quality and output resolution. In this Wild Format article, Paul Lindström talks about the importance of the surface on which the printer stands, the importance of print settings adjustments per substrate and the human factor, or skills, and how these can improve print quality. Read Paul´s article on our articles page via this link.

Print quality of wide format printers is not only influenced by things such as printheads, ink quality and output resolution. In this Wild Format article, Paul Lindström talks about the importance of the surface on which the printer stands, the importance of print settings adjustments per substrate and the human factor, or skills, and how these can improve print quality. Read Paul´s article on our articles page via this link. Bundesverband Druck und Media has made the English version of its “MediaStandard 2016 – Technical Guidelines for Data, proof and Production Run Printing” available online. The publication gives clear directions and tips for the cooperation between print client, designer and producer. The directions are based on the international ISO-12647 norm and the CIEDE2000 for the production of digital samples.

Bundesverband Druck und Media has made the English version of its “MediaStandard 2016 – Technical Guidelines for Data, proof and Production Run Printing” available online. The publication gives clear directions and tips for the cooperation between print client, designer and producer. The directions are based on the international ISO-12647 norm and the CIEDE2000 for the production of digital samples.

The English version can be downloaded via this link.

Lees verder....

Bundesverband Druck und Media heeft een Engelse versie van zijn „MediaStandard Print 2016 – Technical Guidelines for Data, Proof and Production Run Printing“ online beschikbaar gemaakt. De publicatie geeft duidelijke richtlijnen en tips voor de samenwerking tussen drukwerkopdrachtgevers, -ontwerpers en -makers. De richtlijnen zijn gebaseerd op de internationale erkende ISO-12647 norm en de CIEDE200O voor het maken van digitale proeven.

Bundesverband Druck und Media heeft een Engelse versie van zijn „MediaStandard Print 2016 – Technical Guidelines for Data, Proof and Production Run Printing“ online beschikbaar gemaakt. De publicatie geeft duidelijke richtlijnen en tips voor de samenwerking tussen drukwerkopdrachtgevers, -ontwerpers en -makers. De richtlijnen zijn gebaseerd op de internationale erkende ISO-12647 norm en de CIEDE200O voor het maken van digitale proeven.

In 2016 heeft Fujifilm goed gescoord met zijn Onset X vlakbedprinter. Een ongeëvenaard aantal Europese drukkers van de UK tot Polen en van Spanje tot Kroatië, hebben hun bedrijf een nieuwe impuls gegeven met de nieuwe Onset X vlakbedprinter.

De vlakbedprinter, het product van de Fujifilm-Inca Digital samenwerking, wordt ook steeds meer ingezet voor kleine oplagen verpakkingen. De maximale snelheid van 900 m2 per uur is daar ruim voldoende voor. Lees meer over dit Europese succes in onderstaand persbericht.

PRESS RELEASE

Onset X investments spark a year of transformation for print businesses across Europe

Fujifilm today announces that during the course of 2016, an unprecedented number of European printers from the UK to Poland, and from Spain to Croatia, transformed their businesses by investing in the ultimate industrial flatbed, the Onset X.

Drupa 2016 contributed to the number of companies investing in the platform, as it took pride of place in the wide format section of the Fujifilm stand. On-stand sales to German screen printer Bachmann GmbH and to leading UK POS and POP printers, Kolorcraft Group and Augustus Martin, were among those announced at the show. Footfall across the stand was heavy throughout the exhibition, and the Onset X was a major draw for media and customers alike.

Bachmann’s CEO, Pascal Bachmann, is clear on the benefits he sees this platform providing: “with the Onset X3, we feel that the Fujifilm-Inca Digital partnership has taken both productivity and quality to another level altogether,” he says. “Aside from the increase in quality we’ve seen since the installation, the biggest difference we (and our customers) have noticed, is just how quickly we can turn jobs around. I would go so far as to say that I think the Onset X3 is unmatched as a large format machine with the ability to handle both flexible and rigid substrates.

“Modern print companies need to revolutionise to survive,” Bachmann continues. “There can be no complacency. No one can say for sure what the future holds, but what is certain is that those with the most flexibility, adaptability and creativity will thrive. With the Onset X3 and our growing partnership with Fujifilm, we think we have given ourselves the best possible platform to deliver on all of these essential requirements.”

Augustus Martin made its decision to invest in two Onset X2 machines and an X3 as a result of its extensive experience with Inca platforms over many years and across a range of models. “We’ve found the quality and reliability of the Inca platform and the Fujifilm Dimatix inkjet system to be exceptional” says founder and Joint Managing Director, Lascelle Barrow. “The new Onset X series has preserved all the rich hallmarks of its well-earned reputation, while dramatically increasing production capacity – making this investment a relatively easy decision in the end.”

At either end of the year, two European corrugated packaging specialists – Grupondunova in Spain and ProDigital in Croatia – invested in Onset X1 machines, citing the quality, productivity and scalability of the platform as their reasons for investing.

“We wanted to be sure we had the fastest machine on the market, but we were not prepared to compromise on quality to get there,” says ProDigital CEO Denis Cigir. Having spent more than a year exploring options, including upgrading the company’s existing digital press, Cigir came to the conclusion that the production speed and capabilities of the Onset X platform could not be matched by anything else currently on the market. He concludes: “we know that when we do reach a stage at which we need to increase our production speed, we can do so very easily and cost-effectively by scaling up our existing platform to achieve speeds of up to 900m2 per hour.”

Grupondunova’s Director General Jordi Carrió, also had the long-term future in mind when making the investment: “the digital packaging world is still in its infancy,” he explains. “So it was very important for us to find a supplier with the ability and willingness to evolve with us. We were looking for a long-term partner rather than just a supplier, and we felt that Fujifilm was ideally suited to that role. Having identified a trend towards customisation and specialised low-volume packaging, we had recently established a new digital packaging business called Wondu, which we had tasked with taking advantage of the increased opportunities in this exciting market. A lengthy period of trials and testing convinced us that the Onset X printer should sit at the heart of this new business proposition, as it has the performance, quality and speed to ensure we deliver on our promise to our customers.”

The Onset X platform opens the door for short run package printing, sampling and prototyping at high levels of quality, that are proving hugely attractive to the corrugated packaging sector. But whether for packaging, or large format displays, the Onset X series prints onto a wide variety of rigid and flexible materials and produces stunning images for everything, from everyday signage to the highest quality backlit displays for demanding markets, such as cosmetics and luxury consumer goods. The platform’s “Scalable Architecture” design gives customers a future-proof investment, built to allow printhead configurations to change and grow without having to change other parts of the machine. At the upper end, the Onset X3 prints at a blistering 900m2 per hour.

Tudor Morgan, Sign & Display Segment Manager, Fujifilm Europe concludes: “the evidence we have seen over the past year is, that printers are thinking carefully about their long-term future and investing accordingly. In addition to the scalability benefits, Onset X platforms are extremely robust and retain their residual value remarkably well, even years down the line. So in addition to the immediate benefits customers are seeing in increased productivity and quality, the Onset X is an investment that is setting them up for the future.”

Lees verder....

Fujifilm today announces that during the course of 2016, an unprecedented number of European printers from the UK to Poland, and from Spain to Croatia, transformed their businesses by investing in the ultimate industrial flatbed, the Onset X.

Fujifilm today announces that during the course of 2016, an unprecedented number of European printers from the UK to Poland, and from Spain to Croatia, transformed their businesses by investing in the ultimate industrial flatbed, the Onset X.

The flatbed printer is a product of the cooperation between Fujifilm and inca Digital and is increasingly used for smaller numbers for packaging. The maximum speed of 900 m2/hour is more than enough for this. Read more about this European success in the press release below.

PRESSRELEASE

Onset X investments spark a year of transformation for print businesses across Europe

Fujifilm today announces that during the course of 2016, an unprecedented number of European printers from the UK to Poland, and from Spain to Croatia, transformed their businesses by investing in the ultimate industrial flatbed, the Onset X.

drupa 2016 contributed to the number of companies investing in the platform, as it took pride of place in the wide format section of the Fujifilm stand. On-stand sales to German screen printer Bachmann GmBH and to leading UK POS and POP printers, Kolorcraft Group and Augustus Martin, were among those announced at the show. Footfall across the stand was heavy throughout the exhibition, and the Onset X was a major draw for media and customers alike.

Bachmann’s CEO, Pascal Bachmann, is clear on the benefits he sees this platform providing: “With the Onset X3, we feel that the Fujifilm-Inca Digital partnership has taken both productivity and quality to another level altogether,” he says. “Aside from the increase in quality we’ve seen since the installation, the biggest difference we (and our customers) have noticed is just how quickly we can turn jobs around. I would go so far as to say that I think the Onset X3 is unmatched as a large format machine with the ability to handle both flexible and rigid substrates.

“Modern print companies need to revolutionise to survive,” Bachmann continues. “There can be no complacency. No one can say for sure what the future holds, but what is certain is that those with the most flexibility, adaptability and creativity will thrive. With the Onset X3 and our growing partnership with Fujifilm, we think we have given ourselves the best possible platform to deliver on all of these essential requirements.”

Augustus Martin made its decision to invest in two Onset X2 machines and an X3 as a result of its extensive experience with Inca platforms over many years and across a range of models. “We’ve found the quality and reliability of the Inca platform and the Fujifilm Dimatix inkjet system to be exceptional” says founder and Joint Managing Director, Lascelle Barrow. “The new Onset X series has preserved all the rich hallmarks of its well-earned reputation, while dramatically increasing production capacity – making this investment a relatively easy decision in the end.”

At either end of the year, two European corrugated packaging specialists – Grupondunova in Spain and ProDigital in Croatia – invested in Onset X1 machines, citing the quality, productivity and scalability of the platform as their reasons for investing.

“We wanted to be sure we had the fastest machine on the market, but we were not prepared to compromise on quality to get there,” says ProDigital CEO Denis Cigir. Having spent more than a year exploring options, including upgrading the company’s existing digital press, Cigir came to the conclusion that the production speed and capabilities of the Onset X platform could not be matched by anything else currently on the market. He concludes: “We know that when we do reach a stage at which we need to increase our production speed, we can do so very easily and cost-effectively by scaling up our existing platform to achieve speeds of up to 900m2/hr.”

Grupondunova’s Director General Jordi Carrió also had the long-term future in mind when making the investment: “The digital packaging world is still in its infancy,” he explains. “So it was very important for us to find a supplier with the ability and willingness to evolve with us. We were looking for a long-term partner rather than just a supplier and we felt that Fujifilm was ideally suited to that role. Having identified a trend towards customisation and specialised low-volume packaging, we had recently established a new digital packaging business called Wondu, which we had tasked with taking advantage of the increased opportunities in this exciting market. A lengthy period of trials and testing convinced us that the Onset X printer should sit at the heart of this new business proposition, as it has the performance, quality and speed to ensure we deliver on our promise to our customers.”

The Onset X platform opens the door for short run package printing, sampling and prototyping at high levels of quality that are proving hugely attractive to the corrugated packaging sector. But whether for packaging, or large format displays, the Onset X series prints onto a wide variety of rigid and flexible materials and produces stunning images for everything from everyday signage to the highest quality backlit displays for demanding markets such as cosmetics and luxury consumer goods. The platform’s “Scalable Architecture” design gives customers a future-proof investment, built to allow printhead configurations to change and grow without having to change other parts of the machine. At the upper end, the Onset X3 prints at a blistering 900m2 per hour.

Tudor Morgan, Sign & Display Segment Manager, Fujifilm Europe concludes: “The evidence we have seen over the past year is that printers are thinking carefully about their long-term future and investing accordingly. In addition to the scalability benefits, Onset X platforms are extremely robust and retain their residual value remarkably well, even years down the line. So in addition to the immediate benefits customers are seeing in increased productivity and quality, the Onset X is an investment that is setting them up for the future.”

Lees verder....

Decathlon sells in Europe table tennis tables made entirely out of cardboard. Not only the table, but also the net and the bats are made of cardboard.

Decathlon sells in Europe table tennis tables made entirely out of cardboard. Not only the table, but also the net and the bats are made of cardboard.

The PaperPong consists of a table tennis table, 2 bats and a little ball. It weighs 7 kilo and the surface is 160×90 cm.

There are only 500 available in Europe, mainly in France.

Blokboek.com has managed to get hold of one, just because we have a love for anything paper.

You can win the Paper Pong in the raffle next week. Visit the Blokboek.com stand at the Grafische Vakbeurs and give us your business card. Don´t miss the chance and visit our stand number D118.

The Grafische Vakbeurs and Vakbeurs Sign will be held between 14 and 16 March in Gorinchem, the Netherlands and is open daily from 13.00 – 21.00.

Lees verder.... For print shops that need a high production capacity Canon introduced the Océ Colorado 1640. It is the first roll-to-roll printer with the new Canon UVgel print technology. It delivers excellent print quality on various media as well as high production. Read more about the new production printer in the press release below.

For print shops that need a high production capacity Canon introduced the Océ Colorado 1640. It is the first roll-to-roll printer with the new Canon UVgel print technology. It delivers excellent print quality on various media as well as high production. Read more about the new production printer in the press release below.

PRESS RELEASE

maart 8, 2017

MELVILLE, N.Y., March 8, 2017 – Canon U.S.A., Inc. a leader in digital imaging solutions, today announced a new print technology that will offer large format graphics print providers unique levels of print speed, quality, automation, and cost of operation.

Canon, a world leader in imaging solutions, proudly introduces a new 64 inch roll-to-roll printer designed to deliver exceptional productivity for high quality indoor and outdoor graphics. Customers will be able to easily handle peak periods with fully automated media loading of multiple online rolls, confidently print unattended with on-the-fly quality assurance, produce instantly cured prints on a wide variety of media including heat sensitive media, and help cut expenses with segment-leading low operating costs. The Océ Colorado 1640 will transform 64 inch roll-to-roll sign and display printing.

“We are very excited about this revolutionary new game changing technology” said Toyo Kuwamura, executive vice president and general manager, Business Imaging Solutions Group, Canon U.S.A., Inc. “This new technology will help large format print providers to increase their print production while lowering their operating costs, enabling them to profitably grow their business. This technology will have a great business impact on the market including small, midsize and even the large production shops, everyone will benefit.”

UVgel Technology

At the heart of the new Océ Colorado 1640 is Canon’s recently announced UVgel technology. This technology combines a radically new UV curable ink from Canon that instantly gels on contact with the media, an advanced “self-aware” piezoelectric printhead technology, an LED-based UV system that cures without adding any damaging heat to the media, and continuous, on-the-fly, printhead nozzle monitoring and performance compensation. These unique technologies come together to create a 64” roll-to-roll printer that sets new standards for quality, productivity, automation, application range, and operating costs.

Breakthrough Productivity

The new Océ Colorado 1640 is the fastest 64 inch printer on the market. It boasts a top speed of 1710 square feet per hour and delivers high quality, POP prints at 430 square feet per hour faster than any competing system in this segment. The new, technologically advanced UVgel ink instantly gels on contact with media resulting in precise dot gain and positional control, perfectly repeatable images, and instantly cured, durable prints. The state-of-the-art low temperature LED-UV curing system moves independently from the printing carriage thus enabling uniform, post-print UV curing that further contributes to print speed and print quality. Confident unattended printing, automated quality assurance, unattended roll change, and reduced print waste all significantly contribute to overall productivity.

Innovations in Automation

The Océ Colorado 1640 sets a new standard in industrialization and automation. It features a heavy-duty drawer mechanism that holds up to two rolls of media at one time, each weighing up to 110 lbs. The two rolls can be of the same media type and size or different media, and once initialized, the print engine can switch jobs between rolls without operator assistance. If an unknown media is loaded, the printer will automatically measure its thickness and adjust the print gap accordingly. This ensures the best possible print quality and reduces the risk of printhead crashes. This information is then stored in the media library along with other media parameters so that the next time this type of media is loaded, the printer knows exactly how to handle it.

Reliability is key for a true production-oriented printer, and the machine must be able to print while unattended. This is why Canon has developed several innovative technologies for on-the-fly quality assurance and control. The UVgel printheads incorporate patented continuous nozzle monitoring to detect and correct any underperforming nozzles. During each and every printing pass, Canon’s patented nozzle monitoring technology automatically checks all nozzles using acoustic sampling and even detects whether nozzles are going to misfire before they actually do. In the event of nozzle failure, corrective maintenance is automatically performed.

Broad Application Range

The Océ Colorado 1640 is excellent for both indoor and outdoor applications. It delivers a large color gamut, similar to solvent inks but combines this with the environmental benefits and safety profile of latex and UV-cured systems. The result is nearly odorless, VCL-free, durable, colorfast, high quality prints even on the thinnest, most heat-sensitive media. Canon’s unique UVgel technology features ultra-thin ink dispersion with almost no discernible physical profile on the media surface. Prints feel uniquely smooth, unlike other UV ink technologies, and satisfy the highest environmental standards for indoor usage with a virtually odorless profile.

As with all roll-to-roll printers, an important factor in print quality, and subsequently application range, is the accuracy with which the printer advances the media. Built on a heavy, robust frame for class-leading rigidity and equipped with industrial components, the media handling system uses an optical feedback loop that continuously monitors media advance. Using virtually invisible printed index marks at the edges of the media, the system measures media advances in real time to automatically correct the subsequent step size as needed.

Lowest Operating Cost

The Océ Colorado 1640 leads the way in terms of low operating costs. Canon’s unique UVgel technology features ink consumption much lower than competitive technologies, as much as 40 percent lower. This technical advantage is matched with a competitive ink price, making the ink cost of production significantly lower than competing technologies. Looking beyond the easily measured cost savings found in every print, additional savings may be realized through unsurpassed automation features that help reduce operator machine handling time by up to a third compared to competitive products.

“Canon is looking forward to the U.S. debut of this product at the ISA Show in April,” said Toyo Kuwamura, executive vice president and general manager, Business Imaging Solutions Group, Canon U.S.A., Inc. “We know that there has been a lot of anticipation around this technology and we are very excited about what the future will bring.”

In summary, this proprietary UVgel technology, consisting of both inks and print heads from Canon, will offer large format graphics print providers significant benefits to existing eco-solvent or Latex ink technology, including:

- The world’s fastest 64 inch roll-roll printer with a maximum usable print speed of 1710 square feet per hour and a high quality POP mode at 430 square feet per hour.

- Up to 40 percent reduction in ink/printing costs compared to other technologies such as latex

- Industrial designed production printer capable of printing higher print volumes and built to withstand high duty cycles

- Very high print quality across a wide range of applications without having to significantly compromise productivity by reducing speed

- Extremely easy and fast media loading and automatic switching with the support of 2 in-line rolls

- On-the-fly quality assurance technology facilitates unattended printing and reduced print waste

- Automated maintenance provides consistent print quality and higher uptime

Voor printbedrijven die een hoge productie capaciteit op groot formaat nodig hebben, introduceert Canon de Océ Colorado 1640. Het is de eerste roll-to-roll printer met de nieuwe Canon UVgel printtechnologie, die niet alleen een hoge productie, maar ook uitstekende printkwaliteit levert op verschillende media. Lees meer over deze nieuwe productieprinter in het onderstaande persbericht.

Voor printbedrijven die een hoge productie capaciteit op groot formaat nodig hebben, introduceert Canon de Océ Colorado 1640. Het is de eerste roll-to-roll printer met de nieuwe Canon UVgel printtechnologie, die niet alleen een hoge productie, maar ook uitstekende printkwaliteit levert op verschillende media. Lees meer over deze nieuwe productieprinter in het onderstaande persbericht.

De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK