Rob van den Braak

A folding recycable bike helmet, made out of paper, recently won the Dyson Innovation Award in the US. The EcoHelmet is made of honeycomb structured recycled paper is especially constructed to resist considerable force so that is can be used in traffic. The paper is water resistant so can withstand rain as well.

Watch the video about this wonderful invention.

[video_embed url=”https://youtu.be/Bu0Lb0C0UzY” embed_style=”default” width=”400 “]

Lees verder.... Het Zwitserse ISAG heeft een snellere versie uitgebracht van zijn fastBook Professional, het nieuwe model 1000 verwerkt maar liefst 1.000 vellen per uur tot een super vlakliggend fotoboek. Lees meer over de de fastBook Professional 1000 in onderstaand persbericht.

Het Zwitserse ISAG heeft een snellere versie uitgebracht van zijn fastBook Professional, het nieuwe model 1000 verwerkt maar liefst 1.000 vellen per uur tot een super vlakliggend fotoboek. Lees meer over de de fastBook Professional 1000 in onderstaand persbericht.

Meer informatie over de fastBook vindt je op site van ISAG.

PERSBERICHT

The latest ISAG production solution was launched successfully at photokina: the new bookbinding system fastBook Professional.

With numerous orders from leading photo product suppliers, the market entry of fastBook Professional can be considered as a major success.

ISAG now responds to the increasing demands of customers with another powerful version of this new LayFlat binding machine: fastBook Professional 1000.

In comparison to the current version fastBook Professional 600, the new fastBook Professional 1000 processes up to 1,000 sheets by gluing sheet to sheet.Both system versions are designed for the production of LayFlat photo books up to a format of 18″ x 18″, providing first-class quality with 180 degree opening and panoramic photo layout, spread flawless over two pages. Fields of application for premium photo books are wedding photography, fine art photography, exclusive product presentations and many more lucrative segments.

Producers can increase their workflow flexibility with the high-performance and efficient fastBook Professional production solution. The systems are designed to produce 24 hours, 7 days a week.

Compared to other production lines, this system has a space-saving footprint, and the integrated hotmelt technology reduces consumable costs significantly.

For an extraordinary look and special haptics, these photobook production machines run different types of original photo papers (AgX) and digital printing papers.

The fastBook Professional book block system is a 100 % Swiss made development, produced in Switzerland.

18″ x 18″ Professional Flush Mount Quality for B2B

Professional photographers demand vibrant reproductions of their images, and a perfect finishing when it comes to photo book production. For exceptional product quality, the new fastBook Professional bookbinding machine produces flush mount albums with cardboards included between two photo paper sheets.

This book block finishing system will more than satisfy the requirements of photo professional clients. Whether flush mounted wedding albums or coffee-table books with panoramic landscape images, the XXL format up to 18″ x 18″ will meet any expectations regarding quality, image layout, look and feel.

Additional B2B target groups for this kind of photo products are advertising agencies, real estate agencies, or manufacturers of luxury goods and labels, such as cars, jewelery, yachts etc.

Luxury XXL Photo Albums for End Consumers

In the end consumer market, the demand on individual premium photo products is also rising constantly. Consumers are willing to pay higher prices for wonderful flush mounted albums, including their precious wedding memories.

All suppliers of wedding related photo products can additionally benefit from the production variety, the fastBook Professional systems offer: first-class “save-the-date”, invitation or “thank you” cards, photo albums, parent gift books, wedding menu cards and many more.

End customers will appreciate to get all these photo products easily from a single and reliable source, in a consistent and high product quality, thus saving time and effort. They always will come back to purchase this premium products on other occasions (travel books, anniversaries etc.).

The Eversify team recently launched a series of vlogs that clearly illustrate key features of multi-channel publishing.

The Eversify team recently launched a series of vlogs that clearly illustrate key features of multi-channel publishing.

The first video ” automating data import in Eversify” illustrates how you can fully automate the import of data from your actual editorial system with Eversify.

The second video “App and Web Publishing ” shows the high automated diversification of digital content to a range of App- and Web-publishing products with Eversify.

The third video reveals the power of the Eversify One Touch InDesign® plug-in. Or how you can create, enrich and distribute a digital publication from within Adobe InDesign® with a mere click on a button.

The videos are available on the Eversify website via this link.

Lees verder....

Het Eversify team lanceerde enkele vlogs die een aantal belangrijke facetten van multi-channel publishing helder uitleggen.

Het Eversify team lanceerde enkele vlogs die een aantal belangrijke facetten van multi-channel publishing helder uitleggen.

De eerste video “automating data import in Eversify” laat zien hoe je het importeren van data volledig kan automatiseren vanuit het editoriaal systeem met Eversify.

De eerste video “App and Web Publishing” toont hoe digitale content geautomatiseerd gediversifieerd kan worden naar verschillende app en web publishing systemen met Eversify.

Een derde video toont de kracht van de Eversify One Touch InDesign® plug-in. Of hoe je met slechts een klik een digitale publicatie kan maken, verrijken en versturen vanuit Adobe InDesign®.

De video zijn te bekijken op de Eversify site via deze link.

Lees verder....

At its third Heimtextil Xeikon will showcase highly unique wall paper designs produced using its wall decoration production suite. Xeikon will be located in Hall 6, in Frankfurt, from January 10 to 13 2017, next to the Heimtextil theme park. In addition to the live printing of unique wall coverings, the display will feature printed patterns and murals projected using new video mapping techniques. This will provide visitors with a “virtual reality” like experience and present the creativity of digitally produced wallcoverings.

INSPIRE WITH BRAND-NEW POSSIBILITIES

“We have more than 15 years’ experience supporting clients producing innovative wallpaper offerings and are the only supplier that offers a complete tailored solution for this market. At Heimtextil we want to demonstrate the amazing results digital printing can achieve and inspire more designers to embrace the creative freedom and production flexibility digital print enables. Our booth will partly be a ‘black box’ onto which we will use video mapping technology to show the designs our technology is producing during the show. We will be presenting all the different capabilities as realistically as possible so architects and designers can quickly grasp how incorporating digital printing into the mix can revolutionize their practices. Our goal is to inspire them with the brand-new possibilities digital printing of wall coverings and other interior décor offers to them and their clients” states Filip Weymans, Xeikon Vice President of Marketing

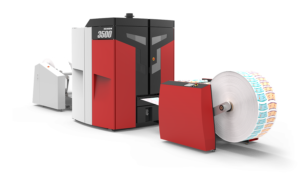

XEIKON 3500

Running on the stand will be Xeikon’s flagship five-colour Xeikon 3500 digital press. It will show how simple and easy it is to produce eye-catching digital print at 600 m2 per hour in widths up to 516mm (20.3”).

The Xeikon 3500 will be demonstrated in a fully functional end-to-end configuration with a Web Varnishing Module (WVM) with aqueous varnish for scratch and scuff protection of the end-product. At the show, Xeikon also demonstrates for the first time its new wallpaper rewinder: the WMR. This unit delivers perfectly finished rolls at the end of the process. This is the most productive solution on the market for digital wallcoverings, photo murals, patterns and short run wallpaper. Sample wall coverings will be produced using an array of new substrates from partners that include Felix Schoeller, Neu Kaliss, Lahnpaper and Glatfelter.

SPECIAL DEVELOPED COATINGS & LIVE PRODUCTION OF WAL COVERINGS

Xeikon and its Aura partners will also be showing special developed coatings that create gold and embossing effects while specific Xeikon colors and UV reflective toners deliver a host of effects that make these digitally printed wall coverings both unique and compelling. And because they are printed digitally on demand, smaller runs are cost-effective to produce, giving architects and interior designers the ability to deliver the kinds of unique interior décor that clients are looking for as they seek to differentiate themselves.

In addition to live production of wall coverings and murals in the stand, an array of additional samples will be on hand to highlight even more possibilities that will further inspire designers and architects.

FANTASTIC OPPORTUNITY

Filip Weymans, “We are excited to be back at Heimtextil in 2017, showcasing unique solutions that will bring value to the Heimtextil audience as they look for ways to differentiate themselves. Attendees will be pleased to learn that the Xeikon dry toner printing process complies with international standards for interior decoration, comprehensively supporting end user requirements. Heimtextil presents a fantastic opportunity for us to engage directly with interior designers and architects and to inspire them to take their interior décor ideas to a new level, and to connect with existing and prospective Xeikon customers who are attending the event.”

Van alle nieuwe digital printing technieken is het bedrukken van textiel de snelst groeiende toepassing. De chemicaliën en inkten die daarvoor gebruikt worden zijn niet allemaal even milieuvriendelijk. In haar Verdigris Blog legt Laurel Brunner uit wat de Oeko-Tex certificatie inhoudt en wat de waarde is van het Eco Passport dat printerfabrikant Epson onlangs behaalde voor zijn textiel printoplossingen. Lees haar blog op onze artikelenpagina.

Van alle nieuwe digital printing technieken is het bedrukken van textiel de snelst groeiende toepassing. De chemicaliën en inkten die daarvoor gebruikt worden zijn niet allemaal even milieuvriendelijk. In haar Verdigris Blog legt Laurel Brunner uit wat de Oeko-Tex certificatie inhoudt en wat de waarde is van het Eco Passport dat printerfabrikant Epson onlangs behaalde voor zijn textiel printoplossingen. Lees haar blog op onze artikelenpagina. Ricoh has launched the Ricoh Pro 8200s series to help print service providers manage varied content in books and brochures, offer a greater number of production sizes and handle more media.

Ricoh has launched the Ricoh Pro 8200s series to help print service providers manage varied content in books and brochures, offer a greater number of production sizes and handle more media.

These allow the high speed black and white digital print platform to enhance and expand the print production capabilities possible.

A wider variety of substrates are now supported and a more creative product mix is enabled by the High Capacity Interposer. It allows front and back covers or inserts, printed on offset or digital printers, to be added post-fusing, into books and manuals. This inline capability also streamlines production.

Another service expanding capability is the long sheet (banner) printing of up to 700mm while an improved stacker allows heavier media use.

Benoit Chatelard, Vice President, Production Printing, Ricoh Europe, says, “The 8200s series empowers printers to produce a wide variety of applications by eliminating manual steps. It supports a greater range of cost-effective services to help the delivery of a broader portfolio of print solutions. It ensures greater flexibility to meet demand for faster turnaround times and tighter deadlines.”

The Ricoh Pro 8200s series can be tailored to suit client needs. It offers users active registration to help ensure more precise, clean output. It can run at speeds of up to 136 ppm, maintain 1,200 x 4,800 dpi VCSEL quality on a wide variety of media, including coated media, up to 350 gsm. It supports NCR and pre-printed media.

Chatelard adds, “Printing on thick and coated media for attractive inserts, running NCR sheets and producing banners helps printers differentiate and add value. While high quality results and flexible set-up support busy production environments. This is a device for the future of high speed production.”

Its durable design and Ricoh’s Trained Customer Replaceable Unit (TCRU) programme work together to help maximise uptime.

The Ricoh Pro 8200s series will have its first European showing at Ricoh’s Open New Worlds events at its Customer Experience Centre in Telford, UK in November; and will be commercially available in Europe from January 2017.

Lees verder....

Matthews International Corporation announced that the Company, through its affiliate, has signed definitive agreements for the purchase of A. + E. Ungricht GmbH + Co KG (hereafter “Ungricht”) and Dornbusch Engraving GmbH (hereafter “Dornbusch”).

Matthews International Corporation announced that the Company, through its affiliate, has signed definitive agreements for the purchase of A. + E. Ungricht GmbH + Co KG (hereafter “Ungricht”) and Dornbusch Engraving GmbH (hereafter “Dornbusch”).

Ungricht is a leading European provider of pre-press services and gravure printing forms, located in Moenchengladbach, Germany. The products and services are sold worldwide. Dornbusch has a profound expertise in embossing rollers and corresponding services, located in Kempen, Germany. The acquisitions are designed to expand Matthews’ products and services in the global surfaces market.

Joseph C. Bartolacci, President and Chief Executive Officer of Matthews, stated, “The combination of our existing businesses with Ungricht and Dornbusch will increase our European production capacities and provide expanded product and service capabilities for our European and global customers.” Terms of the acquisition were not immediately disclosed.

The transactions, which are subject to regulatory approval in Germany, are expected to close during Matthews’ 2017 second fiscal quarter.

Lees verder.... Our industry is seeing massive improvements in ink technologies, especially to suit new print methods and substrates. Technology advances are taking print into all sorts of new applications. One of the most attractive for all concerned is textiles, particularly those produced digitally with devices such as the Epson SureColor SC-F2000 direct-to-garment printer or the EFI Reggiani series. Textile printing brings with it a host of expectations for quality and durability, and when it comes to on demand prototyping there is less price sensitivity in this kind of print. However there are other more important concerns, with product safety at the top of the list.

Our industry is seeing massive improvements in ink technologies, especially to suit new print methods and substrates. Technology advances are taking print into all sorts of new applications. One of the most attractive for all concerned is textiles, particularly those produced digitally with devices such as the Epson SureColor SC-F2000 direct-to-garment printer or the EFI Reggiani series. Textile printing brings with it a host of expectations for quality and durability, and when it comes to on demand prototyping there is less price sensitivity in this kind of print. However there are other more important concerns, with product safety at the top of the list.

As one might expect, there are many standards relating to the safety of printed textiles. The worldwide reference for textile standards is Oeko-Tex. This international association of textile testing institutes has been around for many years and has sixteen members across the globe. The organisation drives innovation in testing and safety in the textile industry, so that users of its services can check that their materials won’t cause harm or illness. Oeko-Tex standards are also used to optimise production and supply chains, so that they are sustainable. A certification from Oeko-Tex ensures independent verification of a company’s safety and sustainability claims.

The latest addition to the Oeko-Tex range of standards and tests is the Eco Passport. Intended for use by chemical and textile manufacturers and suppliers, the Eco Passport confirms that their products can be used in sustainable textile production. The chemicals used in a given product, such as ink, are checked against the Oeko-Tex restricted substance list. They are then analysed for various characteristics, including toxicity, in order to ascertain that the product can be used in the production of sustainable textiles. The mark can only be applied if the chemical product and its preparation meet the conditions of the Eco Passport label.

Epson has recently announced that its inks and printers have now been certified for the Eco Passport. This means that all processing chemicals and compounds used in Epson textile printers and inks are safe and produced in a sustainable way. The certification includes all dyes, additives, finishing agents and detergents as well as inks, so it is a majorly important step for Epson. Epson is reducing the environmental impact of its products, but it is also supporting the sustainability efforts of its customers. When it was launched in 2008, Epson’s Environmental Vision 2050 set a CO2 reduction target of 90% across the whole life cycle of its products, the Oeko-Tex certification confirms that it is making steady progress.

Laurel Brunner

The Verdigris project is an industry initiative intended to raise awareness of print’s positive environmental impact. It provides a weekly commentary to help printing companies keep up to date with environmental standards, and how environmentally friendly business management can help improve their bottom lines. Verdigris is supported by the following companies: Agfa Graphics, EFI, Epson,Fespa, HP, Kodak, Kornit, Ricoh, Spindrift, Splash PR, Unity Publishing and Xeikon

Lees verder.... Out of all new digital printing technology textile printing is the fastest growing solution. Not all chemicals and inks used in this process are equally environmentally friendly. In her Verdigris blog Laurel Brunner explains what Oeko-Tex certification is and the value of the Eco Passport recently given to printer manufacturer Epson for their textile print solutions. Read her blog on our articles page.

Out of all new digital printing technology textile printing is the fastest growing solution. Not all chemicals and inks used in this process are equally environmentally friendly. In her Verdigris blog Laurel Brunner explains what Oeko-Tex certification is and the value of the Eco Passport recently given to printer manufacturer Epson for their textile print solutions. Read her blog on our articles page.

Lees verder....

Our industry is seeing massive improvements in ink technologies, especially to suit new print methods and substrates. Technology advances are taking print into all sorts of new applications. One of the most attractive for all concerned is textiles, particularly those produced digitally with devices such as the Epson SureColor SC-F2000 direct-to-garment printer or the EFI Reggiani series. Textile printing brings with it a host of expectations for quality and durability, and when it comes to on demand prototyping there is less price sensitivity in this kind of print. However there are other more important concerns, with product safety at the top of the list.

Our industry is seeing massive improvements in ink technologies, especially to suit new print methods and substrates. Technology advances are taking print into all sorts of new applications. One of the most attractive for all concerned is textiles, particularly those produced digitally with devices such as the Epson SureColor SC-F2000 direct-to-garment printer or the EFI Reggiani series. Textile printing brings with it a host of expectations for quality and durability, and when it comes to on demand prototyping there is less price sensitivity in this kind of print. However there are other more important concerns, with product safety at the top of the list.

As one might expect, there are many standards relating to the safety of printed textiles. The worldwide reference for textile standards is Oeko-Tex. This international association of textile testing institutes has been around for many years and has sixteen members across the globe. The organisation drives innovation in testing and safety in the textile industry, so that users of its services can check that their materials won’t cause harm or illness. Oeko-Tex standards are also used to optimise production and supply chains, so that they are sustainable. A certification from Oeko-Tex ensures independent verification of a company’s safety and sustainability claims.

The latest addition to the Oeko-Tex range of standards and tests is the Eco Passport. Intended for use by chemical and textile manufacturers and suppliers, the Eco Passport confirms that their products can be used in sustainable textile production. The chemicals used in a given product, such as ink, are checked against the Oeko-Tex restricted substance list. They are then analysed for various characteristics, including toxicity, in order to ascertain that the product can be used in the production of sustainable textiles. The mark can only be applied if the chemical product and its preparation meet the conditions of the Eco Passport label.

Epson has recently announced that its inks and printers have now been certified for the Eco Passport. This means that all processing chemicals and compounds used in Epson textile printers and inks are safe and produced in a sustainable way. The certification includes all dyes, additives, finishing agents and detergents as well as inks, so it is a majorly important step for Epson. Epson is reducing the environmental impact of its products, but it is also supporting the sustainability efforts of its customers. When it was launched in 2008, Epson’s Environmental Vision 2050 set a CO2 reduction target of 90% across the whole life cycle of its products, the Oeko-Tex certification confirms that it is making steady progress.

Laurel Brunner

The Verdigris project is an industry initiative intended to raise awareness of print’s positive environmental impact. It provides a weekly commentary to help printing companies keep up to date with environmental standards, and how environmentally friendly business management can help improve their bottom lines. Verdigris is supported by the following companies: Agfa Graphics, EFI, Epson,Fespa, HP, Kodak, Kornit, Ricoh, Spindrift, Splash PR, Unity Publishing and Xeikon

Lees verder....De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK