Rob van den Braak

Last week Apple announced the new iPhones and a new version of the Apple Watch. Users waiting for a new Mac have to wait a bit longer.

Last week Apple announced the new iPhones and a new version of the Apple Watch. Users waiting for a new Mac have to wait a bit longer.

In a mail to customers, Apple CEO Tim Cook promised that they are working on new Mac models. Cook also said that he loves Mac and that current users do not need to worry. They just have to be patient, or in Cook´s words “stay tuned”.

Analysts say that Apple will introduce a new MacBook Pro first followed by new MacBook Air models. There is talk of new screen with a so-called “5K resolution”. Apple is said to work together with LG on this.

Lees verder....

Canon has announced a new inkjet ink, Canon UVgel. This new ink promises superfast drying times, a wider color gamut and is said to be more environmentally friendly than other or UV inks. The ink comes with a new ¨next generation¨ piezoelectric printhead with acoustic sampling technology that monitors nozzle performance on the fly during printing. According to Canon this results in higher and more consistent print quality.

Canon has announced a new inkjet ink, Canon UVgel. This new ink promises superfast drying times, a wider color gamut and is said to be more environmentally friendly than other or UV inks. The ink comes with a new ¨next generation¨ piezoelectric printhead with acoustic sampling technology that monitors nozzle performance on the fly during printing. According to Canon this results in higher and more consistent print quality.

At SGIA Canon showed a prototype of the UVGel printer, based on the Canon Arizona wide format printers. This new printer should become available next spring. If UVgel will also be suitable for other solutions such as production inkjet we do not know.

Read more about this new development in the press release below.

Lees verder....Canon U.S.A., Inc. Announces Revolutionary New Technology That Will Transform Wide Format Roll-to-Roll Printing

MELVILLE, N.Y., September 14, 2016 – Canon U.S.A., Inc. today announced its new UVgel printing technology. This unique technology will soon be featured in a new line of roll-to-roll printers that will offer large format print providers an unprecedented combination of productivity, image quality, application range, automation and low cost of operation.

“We are very excited to show this revolutionary new game-changing technology at SGIA,” said Toyotsugu Kuwamura, executive vice president and general manager, Business Imaging Solutions Group, Canon U.S.A., Inc. “This new technology will power an upcoming generation of roll-to-roll printers that will help our customers increase their print production efficiency while lowering their operating costs, enabling them to profitably grow their business.”

Key elements and benefits of the UVgel technology:

- A radically new UV curable ink from Canon that instantly gels on contact with the media, resulting in precise dot placement and area control for consistent high-quality images at high speed

- The large color gamut of solvent inks combined with the environmental benefits and safety profile of latex and UV inks

- Ultra-thin ink dispersion with almost no discernible physical profile and the lowest ink consumption rate can provide up to a 40 percent reduction in printing costs compared to eco-solvent and latex

These features all result in cost-effective, non-toxic, durable, color fast, high-quality prints for almost any flexible media application.

This amazing new UVgel technology incorporates several new hardware technology developments from Canon:

- Advanced, “next generation” piezoelectric printhead technology employing patented acoustic sampling technology that monitors nozzle performance on-the-fly during printing

- A unique LED UV curing sub-system that operates completely independently from the printing system ensuring identical jetting to curing timing for every droplet for unprecedented uniformity across the printed image

- An LED-based UV system that cures without adding any heat to the media whatsoever, making it easy to print on the thinnest, most heat-sensitive flexible media

- Continuous, on-the-fly, nozzle performance compensation facilitates confident unattended printing and reduced print waste

Canon’s new UVgel printing technology will be at the core of a family of new roll-to-roll printing products, the first of which will be a high productivity 64 inch roll-to-roll printer to be released in the Spring of 2017. The significant investment in this new technology demonstrates Canon’s continued commitment to be a leader in digital graphics markets. Canon has already proven itself to be a leader in the UV flatbed market with its highly awarded, market leading Océ Arizona series of flatbed printers.

Canon will be showcasing this new UVgel technology in its booth (#1536) at the 2016 SGIA Expo, September 14-16 in Las Vegas.

Canon heeft een nieuwe inkjet inkt aangekondigd, Canon UVgel. De nieuwe inkt belooft supersnelle droogtijden, een grotere kleuromvang en zou milieuvriendelijker moeten zijn dan latex en andere UV-drogende inkten. Bij de inkt hoort een nieuwe ‘next-generation’ piezoelectric printkop die met akoestische sampling on the fly de werking van elke nozzle controleert. Daarmee zou volgens Canon de afdrukkwaliteit hoger en constanter moeten worden. Op de SGIA toonde Canon een prototype van een UVgel printer, gebaseerd op de Canon Arizona groot formaat printers. De nieuwe printer zou volgend voorjaar al beschikbaar moeten zijn. Of UVgel naast groot formaat ook voor andere toepassingen zoals production inkjet geschikt is, is nog niet bekend.

Canon heeft een nieuwe inkjet inkt aangekondigd, Canon UVgel. De nieuwe inkt belooft supersnelle droogtijden, een grotere kleuromvang en zou milieuvriendelijker moeten zijn dan latex en andere UV-drogende inkten. Bij de inkt hoort een nieuwe ‘next-generation’ piezoelectric printkop die met akoestische sampling on the fly de werking van elke nozzle controleert. Daarmee zou volgens Canon de afdrukkwaliteit hoger en constanter moeten worden. Op de SGIA toonde Canon een prototype van een UVgel printer, gebaseerd op de Canon Arizona groot formaat printers. De nieuwe printer zou volgend voorjaar al beschikbaar moeten zijn. Of UVgel naast groot formaat ook voor andere toepassingen zoals production inkjet geschikt is, is nog niet bekend.

Canon U.S.A., Inc. Announces Revolutionary New Technology That Will Transform Wide Format Roll-to-Roll Printing

MELVILLE, N.Y., September 14, 2016 – Canon U.S.A., Inc. today announced its new UVgel printing technology. This unique technology will soon be featured in a new line of roll-to-roll printers that will offer large format print providers an unprecedented combination of productivity, image quality, application range, automation and low cost of operation.

“We are very excited to show this revolutionary new game-changing technology at SGIA,” said Toyotsugu Kuwamura, executive vice president and general manager, Business Imaging Solutions Group, Canon U.S.A., Inc. “This new technology will power an upcoming generation of roll-to-roll printers that will help our customers increase their print production efficiency while lowering their operating costs, enabling them to profitably grow their business.”

Key elements and benefits of the UVgel technology:

- A radically new UV curable ink from Canon that instantly gels on contact with the media, resulting in precise dot placement and area control for consistent high-quality images at high speed

- The large color gamut of solvent inks combined with the environmental benefits and safety profile of latex and UV inks

- Ultra-thin ink dispersion with almost no discernible physical profile and the lowest ink consumption rate can provide up to a 40 percent reduction in printing costs compared to eco-solvent and latex

These features all result in cost-effective, non-toxic, durable, color fast, high-quality prints for almost any flexible media application.

This amazing new UVgel technology incorporates several new hardware technology developments from Canon:

- Advanced, “next generation” piezoelectric printhead technology employing patented acoustic sampling technology that monitors nozzle performance on-the-fly during printing

- A unique LED UV curing sub-system that operates completely independently from the printing system ensuring identical jetting to curing timing for every droplet for unprecedented uniformity across the printed image

- An LED-based UV system that cures without adding any heat to the media whatsoever, making it easy to print on the thinnest, most heat-sensitive flexible media

- Continuous, on-the-fly, nozzle performance compensation facilitates confident unattended printing and reduced print waste

Canon’s new UVgel printing technology will be at the core of a family of new roll-to-roll printing products, the first of which will be a high productivity 64 inch roll-to-roll printer to be released in the Spring of 2017. The significant investment in this new technology demonstrates Canon’s continued commitment to be a leader in digital graphics markets. Canon has already proven itself to be a leader in the UV flatbed market with its highly awarded, market leading Océ Arizona series of flatbed printers.

Papier heeft veel voordelen ten opzichte van plastic als het gaat om hergebruik en milieubelasting bij fabricage. Maar plastic heeft grote voordelen als het gaat om duurzaamheid, sterkte en toepassingsmogelijkheden. Laurel Brunner somt ze allemaal op en gaat ook in op nieuwe technologische ontwikkelingen die een aantal nadelen van plastic op gaan lossen. Lees haar Plastic Dreams artikel op onze longreads pagina.

Papier heeft veel voordelen ten opzichte van plastic als het gaat om hergebruik en milieubelasting bij fabricage. Maar plastic heeft grote voordelen als het gaat om duurzaamheid, sterkte en toepassingsmogelijkheden. Laurel Brunner somt ze allemaal op en gaat ook in op nieuwe technologische ontwikkelingen die een aantal nadelen van plastic op gaan lossen. Lees haar Plastic Dreams artikel op onze longreads pagina.

Lees verder....

Paper is one of the world’s most readily recycled materials. It is based on a renewable resource that aids in the expansion of our planet’s lung capacity. Paper may be our most pervasive substrate, but it is not the only material used in printing and publishing applications. In packaging and in the sign and display sectors, plastic is extremely popular.

Paper is one of the world’s most readily recycled materials. It is based on a renewable resource that aids in the expansion of our planet’s lung capacity. Paper may be our most pervasive substrate, but it is not the only material used in printing and publishing applications. In packaging and in the sign and display sectors, plastic is extremely popular.

Plastic has much to commend it for packaging and signage. It’s durable and can be configured to meet all sorts of requirements, from flexibility to stretchability. It is durable and works well with different print processes. However many of plastic’s strengths are also severe limitations when it comes to recycling and managing end of life. Basically not much of either goes on. Take plastics such as polyethylene terephthalate (PET), commonly used for bottles. It often ends up in landfill where it can take over 400 years to biodegrade or it gets incinerated. This latter option at least has the benefit of contributing to energy generation.

The good news is that technology doesn’t stand still, so other options are coming along. These possibilities offer an interesting prognosis for the recyclability of plastics in the graphic arts. Bioplastics for instance are based on vegetable fats and oils or cornstarch and biodegrade as a result of bacterial activity. We have yet to see bioplastics widely used in the printing business, but we are seeing them used as coatings in packaging.

Another option is to upcycle plastics, so that they can be used in new applications. A small company in New Zealand has developed a technology that turns plastic waste into building blocks. This is a proprietary technology specifically designed to upcycle waste plastic. It uses water held under pressure at very high temperatures ranging from 100ºC and 374ºC, and compresssion, but it does not melt or otherwise degrade the polymers in the plastic. ByFusion’s machine turns the waste plastic into an alternative building material which it calls RePlast. The blocks have undergone testing to ensure that they comply with various building requirements related to compression and shear strength. ByFusion is working hard to make sure that their blocks comply with international requirements. In New Zealand and California these blocks have been used to construct retaining walls without showing signs of degradation. In areas prone to earthquakes these blocks may even be more suitable than concrete blocks, because they are flexible.

The ByFusion process works with pretty much any type of plastic, with the exception of foamed plastics such as polystyrene as these materials lack the structural integrity required for upcycling into building blocks. But coming up with a way to upcycle waste plastic is only a small part of the story. We also need sorting and waste collection streams that get the waste to where it is needed if it is to be a viable raw material. That part of the equation is still missing.

Laurel Brunner

The Verdigris project is an industry initiative intended to raise awareness of print’s positive environmental impact. It provides a weekly commentary to help printing companies keep up to date with environmental standards, and how environmentally friendly business management can help improve their bottom lines. Verdigris is supported by the following companies: Agfa Graphics, EFI, Epson, Fespa, HP, Kodak, Kornit, Ricoh, Spindrift, Splash PR, Unity Publishing and Xeikon.

Lees verder.... Paper has a lot of advantages over plastic in so far as recycling and environment taxes are concerned. But plastic has the big advantage of durability, strength and uses. Laurel Brunner made a list of all pros and cons and includes new technological developments which will counter a few of plastic´s cons. Read her Plastic Dreams article on our longreads page.

Paper has a lot of advantages over plastic in so far as recycling and environment taxes are concerned. But plastic has the big advantage of durability, strength and uses. Laurel Brunner made a list of all pros and cons and includes new technological developments which will counter a few of plastic´s cons. Read her Plastic Dreams article on our longreads page.

Lees verder....

Paper is one of the world’s most readily recycled materials. It is based on a renewable resource that aids in the expansion of our planet’s lung capacity. Paper may be our most pervasive substrate, but it is not the only material used in printing and publishing applications. In packaging and in the sign and display sectors, plastic is extremely popular.

Paper is one of the world’s most readily recycled materials. It is based on a renewable resource that aids in the expansion of our planet’s lung capacity. Paper may be our most pervasive substrate, but it is not the only material used in printing and publishing applications. In packaging and in the sign and display sectors, plastic is extremely popular.

Plastic has much to commend it for packaging and signage. It’s durable and can be configured to meet all sorts of requirements, from flexibility to stretchability. It is durable and works well with different print processes. However many of plastic’s strengths are also severe limitations when it comes to recycling and managing end of life. Basically not much of either goes on. Take plastics such as polyethylene terephthalate (PET), commonly used for bottles. It often ends up in landfill where it can take over 400 years to biodegrade or it gets incinerated. This latter option at least has the benefit of contributing to energy generation.

The good news is that technology doesn’t stand still, so other options are coming along. These possibilities offer an interesting prognosis for the recyclability of plastics in the graphic arts. Bioplastics for instance are based on vegetable fats and oils or cornstarch and biodegrade as a result of bacterial activity. We have yet to see bioplastics widely used in the printing business, but we are seeing them used as coatings in packaging.

Another option is to upcycle plastics, so that they can be used in new applications. A small company in New Zealand has developed a technology that turns plastic waste into building blocks. This is a proprietary technology specifically designed to upcycle waste plastic. It uses water held under pressure at very high temperatures ranging from 100ºC and 374ºC, and compresssion, but it does not melt or otherwise degrade the polymers in the plastic. ByFusion’s machine turns the waste plastic into an alternative building material which it calls RePlast. The blocks have undergone testing to ensure that they comply with various building requirements related to compression and shear strength. ByFusion is working hard to make sure that their blocks comply with international requirements. In New Zealand and California these blocks have been used to construct retaining walls without showing signs of degradation. In areas prone to earthquakes these blocks may even be more suitable than concrete blocks, because they are flexible.

The ByFusion process works with pretty much any type of plastic, with the exception of foamed plastics such as polystyrene as these materials lack the structural integrity required for upcycling into building blocks. But coming up with a way to upcycle waste plastic is only a small part of the story. We also need sorting and waste collection streams that get the waste to where it is needed if it is to be a viable raw material. That part of the equation is still missing.

Laurel Brunner

The Verdigris project is an industry initiative intended to raise awareness of print’s positive environmental impact. It provides a weekly commentary to help printing companies keep up to date with environmental standards, and how environmentally friendly business management can help improve their bottom lines. Verdigris is supported by the following companies: Agfa Graphics, EFI, Epson, Fespa, HP, Kodak, Kornit, Ricoh, Spindrift, Splash PR, Unity Publishing and Xeikon.

Mimaki launched its Tx500P-3200DS, a 3.2m wide direct sublimation printer. This new printer significantly shortens production time because of the simultaneous performance of printing and colour fixation. Two steps become only the one. With printing speeds of up to 130m2/hour the Tx500P-3200DS is not only ideal for the production of samples, but also for bigger productions with a quick turnaround.

Mimaki launched its Tx500P-3200DS, a 3.2m wide direct sublimation printer. This new printer significantly shortens production time because of the simultaneous performance of printing and colour fixation. Two steps become only the one. With printing speeds of up to 130m2/hour the Tx500P-3200DS is not only ideal for the production of samples, but also for bigger productions with a quick turnaround.

“There is a growing demand for soft signage due to its economic and environmental benefits,” said Mike Horsten, General Manager Marketing of Mimaki EMEA. “At the same time, the textile industry is shifting increased volumes from analog to digital printing in order to meet market demand for the growing number of small lot orders and shortened cycle times. The new Tx500P-3200DS was designed specifically to meet these requirements in both segments, as well as the growing demand for digitally printed textiles in home décor, with its requirement for extra-wide fabrics to draperies, linens and upholstery. We are also seeing an increase in custom orders via the Internet that can more easily be fulfilled leveraging the productivity benefits of this printer.”

The details

The Tx500P-3200DS is uniquely suited for a wide array of textile printing, including soft signage, customised apparel, and fabrics for home décor and furnishings. It delivers:

- Print speeds at up to 130 m2/hour with 4-colour printing and up to 105 m2/hour with 6 colours.

- Unmatched print quality with resolution up to 720 x 1080 dpi using 12 print heads in a staggered 3-line array.

- Stable quality enabled to its pulling roller that maintains appropriate pressure during printing onto rolled textiles with widths up to 3,2 meters and weight up to 130 kg.

- Worry-free uninterrupted print operation with automatic detection and cleaning of clogged nozzles, substituting good nozzles for printing during this process. This allows constant printing and reduces waste due to defective nozzles.

- What is truly unique about this printer,” Horsten added, “is the combination of printing and heat fixation in a single pass. Direct sublimation transfer printing requires the fixing of printed inks through heating. In a typical operation, these processes are performed separately, adding time and touches to textile printing. When operations are dealing with very small lots, samples or longer runs with tight delivery schedules, every minute counts. Our goal in bringing this unique configuration to market was to deliver a printer that was more efficient than anything else on the market, and this new printer meets that need.”

Lees verder....

Just like the print industry bag makers are dealing with a saturated market where cheap copies push down margins. The solution found by 1Ateltier, a startup that combines digital technology and craftsmanship, is combining quality and intensive internet marketing. The ease of ordering via the web combined with quality which previously could only be found in luxury brands such as Chanel or Hermes has ensured a flying start for the 1Atelier. The parallel with the print industry is easier than expected. There has to be a market for better greeting cards, bound photobooks, unique business cards and other printed materials. A market that wants quality and the speed of ordering and delivery they are accustomed to because of the internet and is willing to pay for this. Read 1Atelier´s story via this link and be inspired to look for that market for your own enterprise.

Just like the print industry bag makers are dealing with a saturated market where cheap copies push down margins. The solution found by 1Ateltier, a startup that combines digital technology and craftsmanship, is combining quality and intensive internet marketing. The ease of ordering via the web combined with quality which previously could only be found in luxury brands such as Chanel or Hermes has ensured a flying start for the 1Atelier. The parallel with the print industry is easier than expected. There has to be a market for better greeting cards, bound photobooks, unique business cards and other printed materials. A market that wants quality and the speed of ordering and delivery they are accustomed to because of the internet and is willing to pay for this. Read 1Atelier´s story via this link and be inspired to look for that market for your own enterprise.

Xitron, de maker van RIP en workflow oplossingen voor bijna alle output devices, introduceert op Graph Expo een netwerk oplossing waarmee CtP belichters, imagesetters en printers via een ethernet-interface aangestuurd kunnen worden. Met interface, B3, wordt het aansturen van output devices nog simpeler voor elke gebruiker. Lees meer over deze revolutionaire oplossing in onderstaand persbericht.

Xitron Network CTP Interface to be Shown at Graph Expo

Xitron Network CTP Interface to be Shown at Graph Expo

—

Coincides with North American introduction of Raster Blaster 4.0

Ann Arbor, MI – September 19, 2016 – Xitron, the leading independent developer of RIP and workflow products for commercial, digital, and high-speed inkjet printing has announced that Graph Expo will be the North American launch venue for two new products. Raster Blaster 4.0, the industry’s first “intelligent” TIFF catcher will make its debut along with the much-anticipated Xitron network CTP interface, known as B3.

“B3 and Raster Blaster 4.0 are next generation products that change the way prepress workflows communicate with computer-to-plate systems,” said Xitron Product Manager Jeffrey Piestrak. “B3 eliminates the need for a dedicated computer platform to act as a CTP TIFF catcher, localizing the interface directly on the network. Besides saving hundreds of dollars in additional cost, B3 offers complete flexibility with regard to equipment location in the shop.”

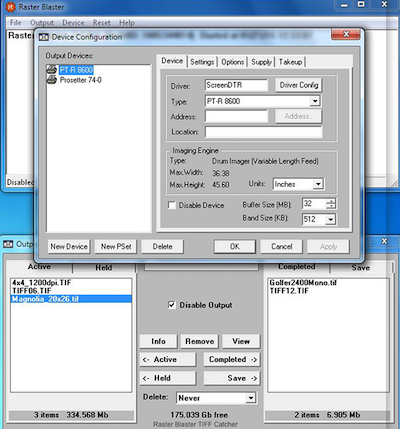

Raster Blaster 4.0 is a browser-based window into plate production, providing output control from anywhere on the network as well as through smart phones and tablets. Performance data and media usage are automatically tracked and operators can export detailed reports with intelligent filtering. Raster Blaster 4.0 can be used in conjunction with B3 or with existing Xitron USB interfaces as an upgrade from earlier versions of the software.

Xitron has an installed base of over 30,000 Navigator RIPs and workflows and nearly 5,000 Raster Blaster TIFF Catchers worldwide. Driving CTP devices from Agfa, ECRM, Creo, Kodak, Presstek, Heidelberg, Fuji, and Screen, they provide prepress independence® to customers who want to maximize their investments by extending the life of their prepress systems. Xitron will be exhibiting in booth 941 at Graph Expo in Orlando, September 25th through the 28th. More information is available at www.xitron.com.

Lees verder.... Xitron, the leading independent developer of RIP and workflow products for commercial, digital, and high-speed inkjet printing has announced that Graph Expo will be the North American launch venue for two new products. Raster Blaster 4.0, the industry’s first “intelligent” TIFF catcher will make its debut along with the much-anticipated Xitron network CTP interface, known as B3.

Xitron, the leading independent developer of RIP and workflow products for commercial, digital, and high-speed inkjet printing has announced that Graph Expo will be the North American launch venue for two new products. Raster Blaster 4.0, the industry’s first “intelligent” TIFF catcher will make its debut along with the much-anticipated Xitron network CTP interface, known as B3.

“B3 and Raster Blaster 4.0 are next generation products that change the way prepress workflows communicate with computer-to-plate systems,” said Xitron Product Manager Jeffrey Piestrak. “B3 eliminates the need for a dedicated computer platform to act as a CTP TIFF catcher, localizing the interface directly on the network. Besides saving hundreds of dollars in additional cost, B3 offers complete flexibility with regard to equipment location in the shop.”

Raster Blaster 4.0 is a browser-based window into plate production, providing output control from anywhere on the network as well as through smart phones and tablets. Performance data and media usage are automatically tracked and operators can export detailed reports with intelligent filtering. Raster Blaster 4.0 can be used in conjunction with B3 or with existing Xitron USB interfaces as an upgrade from earlier versions of the software.

Xitron has an installed base of over 30,000 Navigator RIPs and workflows and nearly 5,000 Raster Blaster TIFF Catchers worldwide. Driving CTP devices from Agfa, ECRM, Creo, Kodak, Presstek, Heidelberg, Fuji, and Screen, they provide prepress independence® to customers who want to maximize their investments by extending the life of their prepress systems. Xitron will be exhibiting in booth 941 at Graph Expo in Orlando, September 25th through the 28th. More information is available at www.xitron.com.

Lees verder....De trainingen voor 2022 staan gereed. Kijk voor het volledige online aanbod van bestaande- en nieuwe trainingen op de website.

BLOKBOEK.COM EN PRINTMEDIANIEUWS: HET OPTIMALE DOELGROEP BEREIK